Automatically apply for jobs with Zippia

Upload your resume to get started.

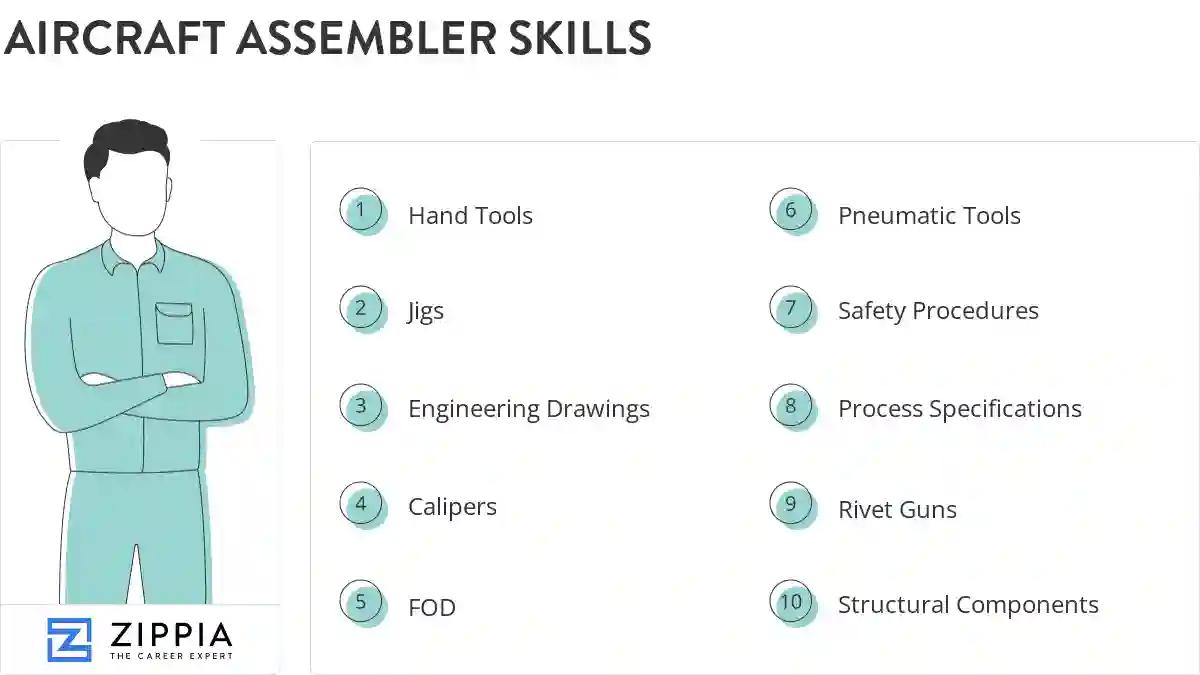

Aircraft assembler skills for your resume and career

15 aircraft assembler skills for your resume and career

1. Hand Tools

- Use various pneumatic tools, hand tools, and precision tools to layout, drill, ream and countersink precision holes.

- Clean, oil, assemble, and attach parts, using hand tools, power tools, and measuring instruments.

2. Jigs

- Created precision bends of various degrees, through both hand measurement and preformed jigs.

- Operated jig fixtures and heavy metal drills.

3. Engineering Drawings

Engineering drawings are technical drawings that tell about the requirements for engineering components or equipment. Such drawings have standardized languages and symbols. There are multiple types of engineering drawings such as isometric drawing, orthographic or multiview drawing, schematic drawings, one view, and two view drawings, etc.

- Read and interpret blueprints, assembly orders, engineering drawings and other work instructions to assemble components per quality specifications.

- Used EWI (Electronic Work Instructions) engineering drawings, hand and pneumatic tools in assembling aircraft components.

4. Calipers

- Utilized precision measuring instruments such as micrometers, calipers, rulers and scribes in the performance of duties.

- Use of precision measurement tools including micrometer, calipers and scales.

5. FOD

FOD is the safety and quality control process followed in environments where loose objects, wildlife and small debris make cause damage to equipment, employees, visitors, or passengers. In worse cases, it will also lead to production delays and violation of safety regulations.

- Followed aviation/company Tool Control and FOD procedures.

- Trained in FOD, which included how to detect and remove unwanted debris before causing damage to the product.

6. Pneumatic Tools

- Assembled air-conditioning units for semis using pneumatic tools

- Hired on as a casual to help assemble engines and transmissions on an assembly line using torque wrenches and pneumatic tools.

Choose from 10+ customizable aircraft assembler resume templates

Build a professional aircraft assembler resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your aircraft assembler resume.7. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Operate machinery and equipment, following established safety procedures.

- Organized work station and followed safety procedures at all times.

8. Process Specifications

Process Specifications refers to a method of outlining how a decision is made within data structures. By documenting each step in the decision-making process, one can determine how the data inputted changed to the outputted data, which may influence any affected engineering or regulatory requirements.

- Performed drilling, rivets and threaded fasteners, inserts and properly prepared sealant/adhesives for process specifications.

- Understand blue prints, and use process specifications in order to install/do the job correctly.

9. Rivet Guns

- Assembled rowing machines working both on a line and assembling parts on own using rivet guns, air and hand tools

- Used a variety hand tools, rivet guns, scanning tools and testing of final product.

10. Structural Components

- Assembled aircraft fuselages in accordance with blueprint specifications, repaired, treated and primed damaged aircraft structural components

- Performed operational checks of aircraft structural components with or without production aids.

11. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Perform duties as outlined in established Job Safety Analysis and National Quality Standards and meet established hourly production goals.

- Assembled medical components in clean room environment while following company procedures effectively maximizing production output while meeting quality standards.

12. Aircraft Systems

Aircraft systems refer to the subsystems necessary for the efficient and safe operation of an aircraft, including flight controls, landing gear, electrical systems, hydraulics, avionics, navigation, communications, and instrumentation. All aircraft require essential systems such as engine, propeller, induction, ignition systems, as well as fuel, lubrication, cooling, electrical, landing gear, and environmental control systems to aid flight. Understanding aircraft systems in flight is essential for safe operation and proper maintenance.

- Performed routine production assembly operations on wiring and electrical sub/assemblies and aircraft systems.

- Trouble shooting Problems with in various aircraft systems.

13. Plumbing

- Fitted and installed plumbing, hydraulic and/or pressure systems (both removable and permanent).

- Installed aircraft skin, frame work, plumbing, and wiring.

14. Aircraft Assembly

- Sheet metal fabrication and aircraft assembly

- Operated station on fast-moving aircraft assembly line while monitoring activity for efficiency, quality, and safety at all times.

15. Aircraft Structures

- Align major aircraft structures, body parts, flight controls and landing gear assemblies

5 Aircraft Assembler resume examples

Build a professional aircraft assembler resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your aircraft assembler resume.

What skills help Aircraft Assemblers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of aircraft assembler skills to add to your resume

The most important skills for an aircraft assembler resume and required skills for an aircraft assembler to have include:

- Hand Tools

- Jigs

- Engineering Drawings

- Calipers

- FOD

- Pneumatic Tools

- Safety Procedures

- Process Specifications

- Rivet Guns

- Structural Components

- Quality Standards

- Aircraft Systems

- Plumbing

- Aircraft Assembly

- Aircraft Structures

- Electrical Systems

- Landing Gear

- Torque Wrenches

- Fastener Installation

- FAA

- Clips

- Shop Equipment

- Aircraft Components

- Assembly Line

- Tolerance Holes

- Hazardous Materials

- Test Equipment

- Mechanical Components

- F-35

- C-17

- Reference Points

- Drill Holes

- Blueprint Specifications

- Air Tools

- Reamers

- MES

- Fuel Systems

- Drill Motors

- F-16

- Engineering Specifications

- Precision Tools

- Drill Press

- Assembly Tools

- Functional Performance

- Gulfstream

Updated January 8, 2025