What does an assembly supervisor do?

Assembly Supervisors oversee and coordinate employees' work on assembly-lines. The supervisors assign personnel to stations or tasks and prepare their work schedules. They monitor processes to make sure that the employees are carrying out their tasks correctly. It is their responsibility to monitor the whole assembly process for delay prevention. They also contribute to developing procedures and processes to boost the overall operation of the assembly lines.

Assembly supervisor responsibilities

Here are examples of responsibilities from real assembly supervisor resumes:

- Manage manufacturing department operations to ensure compliance with establish quality specifications, production levels, and FDA regulations.

- Assemble and test home improvement products (gas grills, lawn tractors, snow blowers, etc .).

- Complete all paper work per ISO and FDA regulations.

- Company's representative for BAMA organization for Toyota suppliers.

- Review project drawings to QC builds according to specifications.

- Define projects to improve the manufacturing processes for CdV base on Chrysler core processes.

- Engage the team to continuously improve the manufacturing processes to meet ISO and NASA certifications.

- Monitor control plans, troubleshoot workmanship problems and supervise production activities to ensure manufacture products meet or exceed establish quality requirements.

- Monitor production line OEE, process capability, and SPC control chart and any key indicator.

- Monitor and recommend resolves of quality document control systems (including SPC) to ensure compliance with customers and ISO audits.

- Operate a forklift and RF scan- manufacturing industry as a leader.

- Offer CNC machining and custom sheet metal fabrication for electronic/computer components to customers.

- Select as site TPM implementation leader, working with multiple sites to develop systems and roll out to teams.

- Utilize TPS techniques to standardize process/methods, identify waste, methodically eliminate waste and standardize the new process/ methods.

Assembly supervisor skills and personality traits

We calculated that 12% of Assembly Supervisors are proficient in Continuous Improvement, Lean Manufacturing, and Safety Procedures.

We break down the percentage of Assembly Supervisors that have these skills listed on their resume here:

- Continuous Improvement, 12%

Created strong, cohesive teams focused on continuous improvement, waste identification/ elimination and sustained levels of performance and customer satisfaction.

- Lean Manufacturing, 10%

Applied knowledge on Lean manufacturing to supplier locations; efficiently converted existing garage facilities into prototype assembly facilities.

- Safety Procedures, 7%

Follow and enforce detailed instructions on proper laboratory safety procedures.

- Corrective Action, 5%

Resolve personnel problems by analyzing data, investigating issues, identifying solutions and executing appropriate corrective actions.

- Production Schedules, 5%

Co-developed production schedule to maintain an efficient production time line to ensure on time customer delivery.

- Quality Standards, 5%

Achieved ISO 9000 compliance by qualifying suppliers, quality standards and using administrative accountability and production procedures.

Most assembly supervisors use their skills in "continuous improvement," "lean manufacturing," and "safety procedures" to do their jobs. You can find more detail on essential assembly supervisor responsibilities here:

The three companies that hire the most assembly supervisors are:

- Kimco Staffing Services Inc22 assembly supervisors jobs

- Goodman Manufacturing9 assembly supervisors jobs

- Metalcraft of Mayville7 assembly supervisors jobs

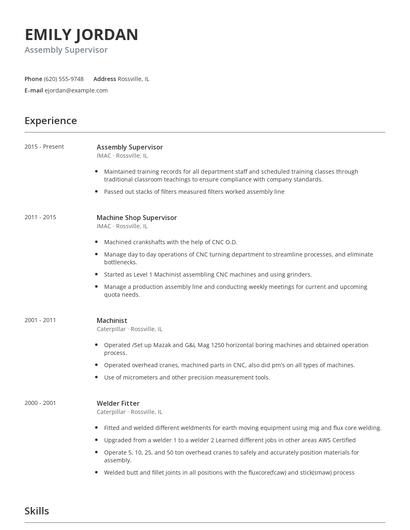

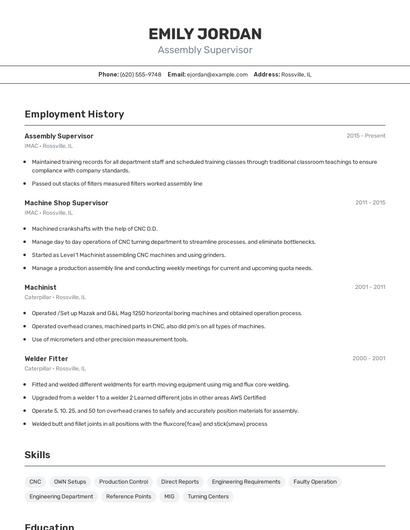

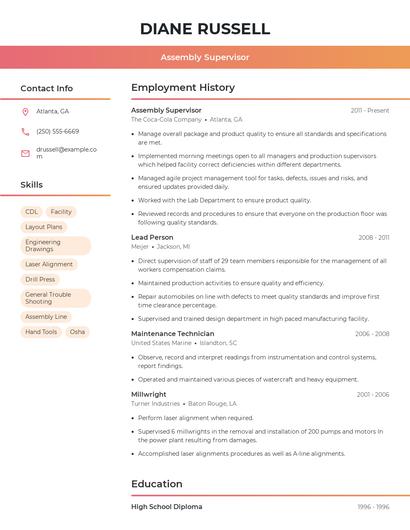

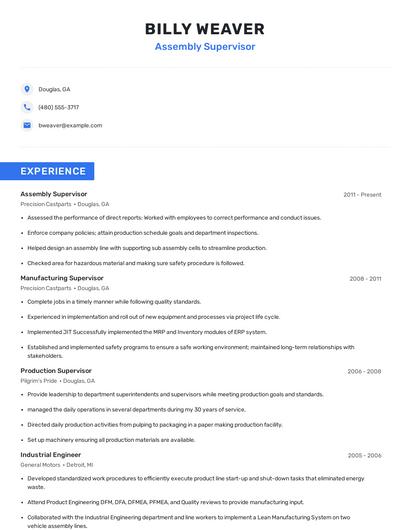

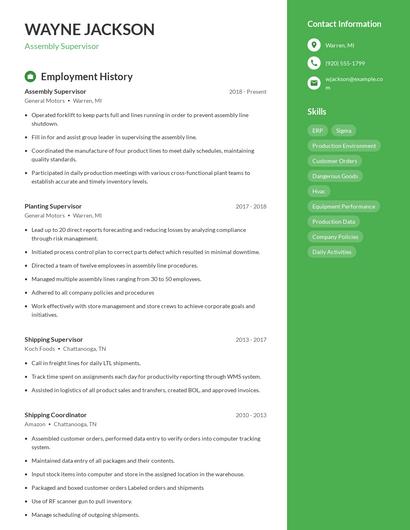

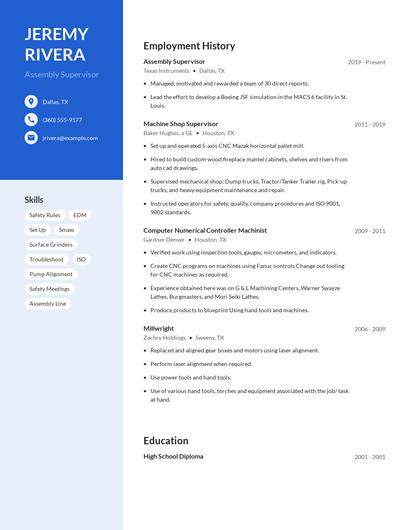

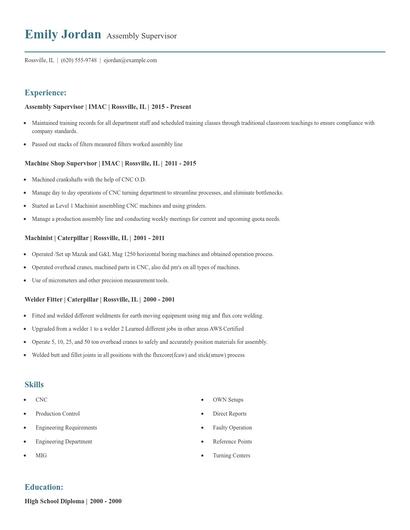

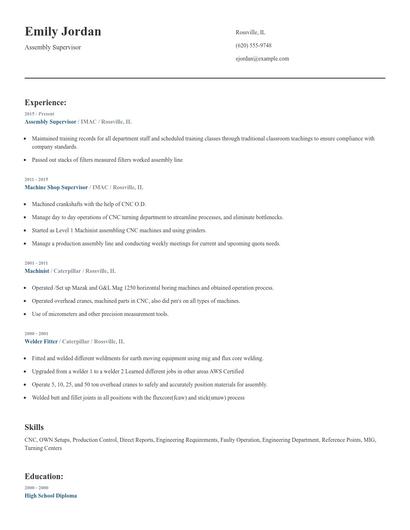

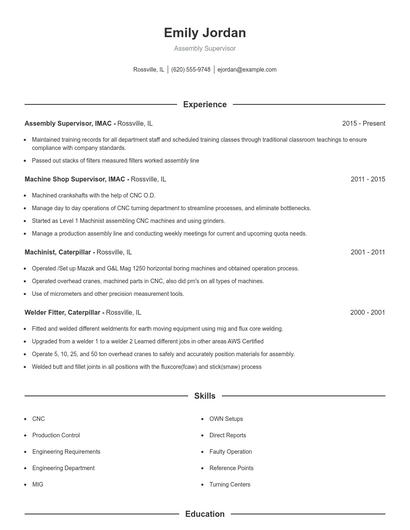

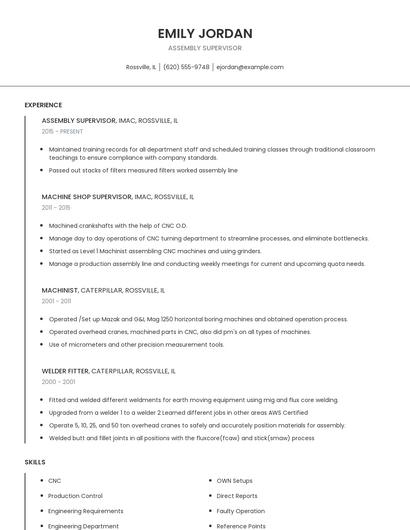

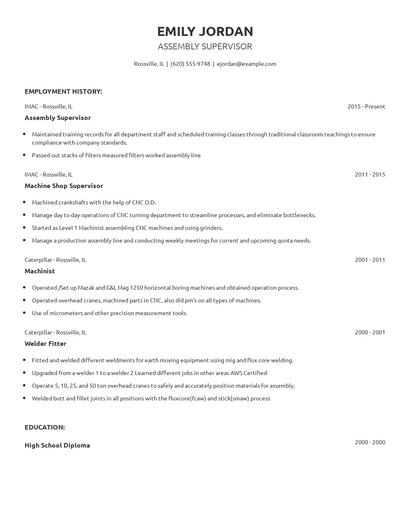

Choose from 10+ customizable assembly supervisor resume templates

Build a professional assembly supervisor resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your assembly supervisor resume.Compare different assembly supervisors

Assembly supervisor vs. Production supervisor/manager

Production supervision managers display strong skills in supervision, decision-making, effective planning, and also have a keen eye for detail. This career will call on the maintenance of a production line's operations, as well as the ongoing production of the end product, in addition to maximizing production while maintaining quality products and staff safety.

These skill sets are where the common ground ends though. The responsibilities of an assembly supervisor are more likely to require skills like "assembly line," "assembly operations," "delivery dates," and "assembly procedures." On the other hand, a job as a production supervisor/manager requires skills like "production supervisors," "production facility," "r," and "production operations." As you can see, what employees do in each career varies considerably.

Production supervisors/manager tend to reach similar levels of education than assembly supervisors. In fact, production supervisors/manager are 2.8% more likely to graduate with a Master's Degree and 0.3% more likely to have a Doctoral Degree.Assembly supervisor vs. Shift production supervisor

A shift production supervisor is in charge of overseeing business operations, ensuring efficiency and smooth workflow. Their responsibilities revolve around devising strategies to reach production standards and production targets, supervising and assessing staff performance, delegating tasks, managing schedules, and prioritizing customer satisfaction. They may also produce progress reports and presentations, address and resolve any issues or concerns, and train new workforce members. Furthermore, as a supervisor, it is essential to lead and encourage team members, all while implementing the company's policies and regulations.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that assembly supervisor responsibilities requires skills like "assembly line," "assembly operations," "delivery dates," and "assembly procedures." But a shift production supervisor might use other skills in their typical duties, such as, "osha," "lean six sigma," "gmp," and "develop team."

Shift production supervisors may earn a lower salary than assembly supervisors, but shift production supervisors earn the most pay in the technology industry with an average salary of $37,043. On the other hand, assembly supervisors receive higher pay in the automotive industry, where they earn an average salary of $79,821.shift production supervisors earn similar levels of education than assembly supervisors in general. They're 0.4% more likely to graduate with a Master's Degree and 0.3% less likely to earn a Doctoral Degree.Assembly supervisor vs. Manufacturing supervisor

A manufacturing supervisor is a management-level employee who takes responsibility for the daily operations of the production processes in the manufacturing sector. Manufacturing supervisors execute different roles as sponsors, coaches, directors, counselors, and educators. They supervise staff, organize the production team, and monitor the overall workflow. There are necessary skills for this position, including adaptability, cooperation, verbal and written communication, and conflict resolution. The supervisors are also expected to be skilled in mentorship and in making a sound decision.

The required skills of the two careers differ considerably. For example, assembly supervisors are more likely to have skills like "assembly operations," "delivery dates," "assembly procedures," and "assembly production." But a manufacturing supervisor is more likely to have skills like "gmp," "direct supervision," "fda," and "lean six sigma."

Manufacturing supervisors earn the highest salary when working in the pharmaceutical industry, where they receive an average salary of $85,664. Comparatively, assembly supervisors have the highest earning potential in the automotive industry, with an average salary of $79,821.Most manufacturing supervisors achieve a similar degree level compared to assembly supervisors. For example, they're 4.6% more likely to graduate with a Master's Degree, and 0.2% more likely to earn a Doctoral Degree.Assembly supervisor vs. Production supervisor

Production supervisors are employees who oversee the production process, usually handling activities directly related to people management. They manage employees by ensuring that the production floor employees are doing their work well and are motivated. Production supervisors guide employees and ensure that everyone is working towards company goals. They properly communicate these goals as well as the strategies to meet the set goals. Production supervisors have a direct hand in the hiring and subsequent training of employees. They should have good communication skills, decision-making skills, and leadership skills.

Types of assembly supervisor

Updated January 8, 2025