Automatically apply for jobs with Zippia

Upload your resume to get started.

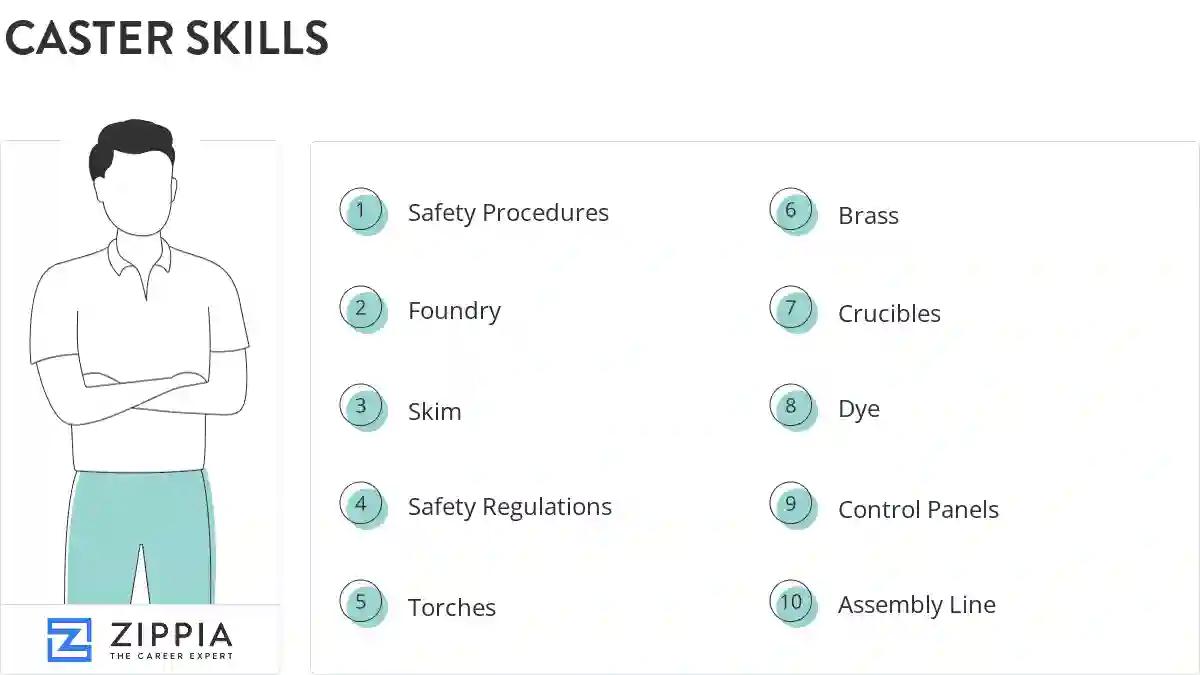

Caster skills for your resume and career

12 caster skills for your resume and career

1. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Follow all safety procedures involved with the handling and production process with molten metal.

- Produced castings, maintained work area, followed production and safety procedures.

2. Foundry

- Melt nickel for US mint foundry as well as brass and other copper alloys.

3. Skim

- Skim dross off the surface of molten aluminum before cast.

- Skim slag or remove excess metal from tundish collect scrap for recycling.

4. Safety Regulations

- Maintained safety regulations to prevent injury.

- Attend three safety webinars monthly to stay current on all safety regulations and weekly meetings for obtaining work goals.

5. Torches

- Melt metal pieces, using torches, and cast products, such as inlays and crowns, using centrifugal casting machines.

- Melt metal pieces, using torches, and cast products, such as inlays and crowns, using centrifugal casting machines.

6. Brass

- Mixed molted metals according to specific formulations to create copper, brass, and nickel alloys.

- Designed custom jewelry using gold, silver, platinum, diamonds, and brass.

7. Crucibles

- Load specified amounts of metal and flux into furnaces or clay crucibles.

- Use fluxing tubes with Argon and SF6 gas for degassing furnaces and crucibles with molten aluminum.

8. Dye

- Dye changes, minor maintainence, one person conveyor belt, stack ware for production, and selected ware for production.

9. Control Panels

A control panel is a flat, enclosed unit, often the vertical part of a system in which the control or monitoring instruments are displayed and accessible to users. Control panels are typically closed-circuit boards with connections to all peripheral devices in their area. They can be found in factories to monitor and control machines or production lines and in places like nuclear power plants, ships, airplanes, and mainframe computers.

- Monitor and operate control panel, pre-stuff fixtures, load fixtures, inspect plates, load and unload plates.

10. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Lifted and loaded toilet bowls onto an assembly line.

11. Production Equipment

Production equipment in limited terms is used to define any type of machinery or equipment used in the production of a video or film. Basic production equipment includes a camera, tripod, lighting kit, camera light, short term microphone, light reflector, boom pole, shock mount, audio cables, wireless microphone, headphones, portable digital audio recorder, camera lenses, extra batteries, external hard drive, and DSLR shoulder mount rig.

- Ensured that production equipment is functioning within operating parameters correctly.

- Ensured that production equipment is producing or processing castings that meet the customer's quality requirements.

12. Urinals

- Manufacture bathtubs, urinals, sinks and toilets.

- Cast toilets and urinals from plaster molds.

What skills help Casters find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of caster skills to add to your resume

The most important skills for a caster resume and required skills for a caster to have include:

- Safety Procedures

- Foundry

- Skim

- Safety Regulations

- Torches

- Brass

- Crucibles

- Dye

- Control Panels

- Assembly Line

- Production Equipment

- Urinals

Updated January 8, 2025