Automatically apply for jobs with Zippia

Upload your resume to get started.

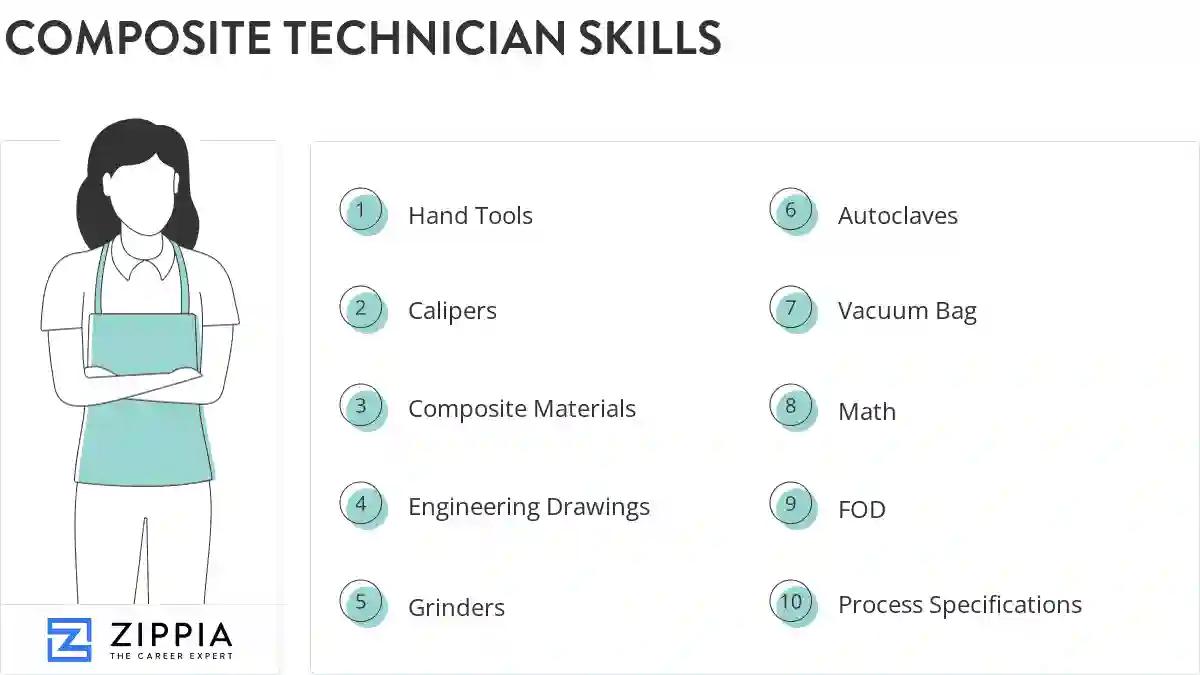

Composite technician skills for your resume and career

15 composite technician skills for your resume and career

1. Hand Tools

- Operate various hand tools pneumatic and electric, cut parts to spec's according to work order and or customers request.

- Used pneumatic hand tools such as drills, SEMCO guns, rivet shavers and vacuums to assemble and bond composite structures.

2. Calipers

- Use precision measuring tools (calipers, scales and micrometers) to check work performed.

- Verify dimensions of products, using calipers, Vernier gauges, or protractors.

3. Composite Materials

A composite material in the engineering and scientific world refers to materials made using two or more different substances. Each of these has varying chemical and physical properties, and they usually combine to form materials with high resistance to pressure and heat. The newly formed material is also more robust and offers a variety of applications.

- Designed and produced composite material patterns for processing into aerospace, automotive, recreational, and industrial applications.

- Handled and applied advanced composite materials into regulated aircraft parts in accordance to specific work instructions

4. Engineering Drawings

Engineering drawings are technical drawings that tell about the requirements for engineering components or equipment. Such drawings have standardized languages and symbols. There are multiple types of engineering drawings such as isometric drawing, orthographic or multiview drawing, schematic drawings, one view, and two view drawings, etc.

- Interpret engineering drawings, understand and apply work instructions, and accurately follow instructions related to composite layup and assembly manufacturing.

- Excelled at following both written and verbal instructions for engineering drawings in order to develop composite hardware fabrication and assembly processes/tooling.

5. Grinders

- Use pneumatic tools such as air drills and die grinders to complete tasks with resins, specifically EA-9309 and EA-956.

- Tool preparation and Finishing with power tools; Grinders, Sanders, Jig Saw, Drills, Skill Saws.

6. Autoclaves

- Assist in loading autoclaves and\or ovens with the use of forklifts, cranes or handling carts.

- Operate full scale equipment, such as autoclaves, ovens, and layup systems.

Choose from 10+ customizable composite technician resume templates

Build a professional composite technician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your composite technician resume.7. Vacuum Bag

- Vacuum bagging inspection and curing oven operation

- Set up molds for vacuum bag with peel ply, release/perforated film, breather/bleeder, vacuum connections and do leak check.

8. Math

- Use of math, scientific calculator, computers, document creation.

- Enter correct data into computer system and double check all math calculations.

9. FOD

FOD is the safety and quality control process followed in environments where loose objects, wildlife and small debris make cause damage to equipment, employees, visitors, or passengers. In worse cases, it will also lead to production delays and violation of safety regulations.

- Practice and ensured all assemblies and detail parts are free of Foreign Object Debris (FOD) and non-conformances.

- Work in both FOD critical and FOD sensitive environments, and observe all related safety procedures.

10. Process Specifications

Process Specifications refers to a method of outlining how a decision is made within data structures. By documenting each step in the decision-making process, one can determine how the data inputted changed to the outputted data, which may influence any affected engineering or regulatory requirements.

- Developed and implemented the paint manufacturing process specifications.

- Build aircraft composite parts using prepreg materials per blue print, process specifications and shop orders.

11. FAA

FAA (Federal Aviation Administration) is an aviation regulatory body in the USA.

- Followed the FAA standards to ensure compliance of all Military and Commercial engines.

- Use measuring tools to ensure that composite meets FAA and company guidelines.

12. Expiration Dates

- Check expiration dates of materials prior to use, prepare proper mixes of resins and catalysts.

- Check all material expiration dates to prior to wrapping.

13. Aircraft Components

- Maintain structural and non-structural composite aircraft components.

- Refurbished and repaired interior commercial aircraft components.

14. Basic Math

- Clean up trash, operate electrical tools, use basic math and measurements.

- Use basic math knowledge (decimals, fractions, adding/subtracting).

15. Composite Components

- Overhauled composite components and general sheet metal repairs.

- Repaired aircraft composite components as needed.

5 Composite Technician resume examples

Build a professional composite technician resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your composite technician resume.

What skills help Composite Technicians find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of composite technician skills to add to your resume

The most important skills for a composite technician resume and required skills for a composite technician to have include:

- Hand Tools

- Calipers

- Composite Materials

- Engineering Drawings

- Grinders

- Autoclaves

- Vacuum Bag

- Math

- FOD

- Process Specifications

- FAA

- Expiration Dates

- Aircraft Components

- Basic Math

- Composite Components

- OSHA

- Blueprint Dimensions

- Lean Manufacturing

- Cleanliness

- Control Procedures

- Technical Specifications

- Band Saws

- Protractors

- CNC

- Bonds

- Composite Structures

- Statistical Process

- R

- Pneumatic Tools

- Wet Lay-Up

- Stabilizers

- Jigs

- Shop Aids

- Composite Repairs

- PPE

- Shop Equipment

- Kevlar

- Epoxy Resins

- Hand Lay-Up

- Woven Material

- Structural Adhesives

- Pre-Preg Materials

- Fastener Applications

- Air Tools

Updated January 8, 2025