Automatically apply for jobs with Zippia

Upload your resume to get started.

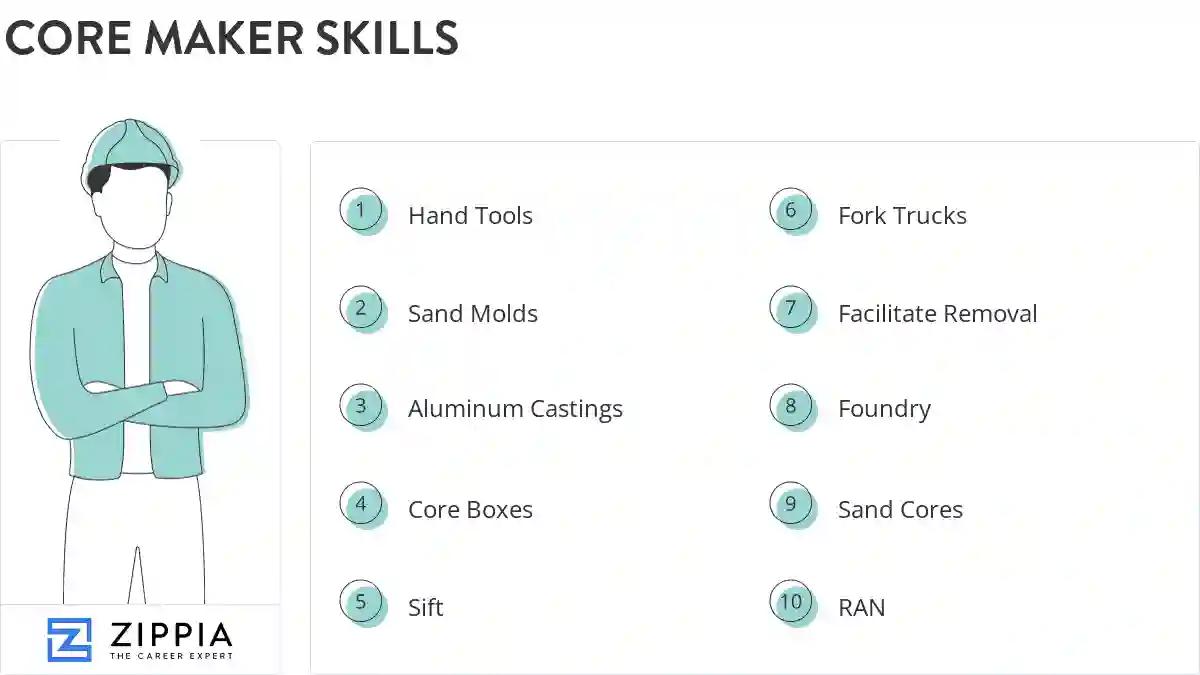

Core maker skills for your resume and career

14 core maker skills for your resume and career

1. Hand Tools

- Formed sand molds to fabricate metal castings, using patterns and match plates, flasks, hand tools and power tools.

- Dressed cores, using hand tools and power tools such as files, scrapers and grinding wheel.

2. Sand Molds

- Worked alongside others to effectively set cores into sand molds.

- Hand pour sand molds with aluminum.

3. Aluminum Castings

- Operated hydraulic aluminum permanent mold machine and made aluminum castings.

4. Core Boxes

- Sifted and packed sand into mold sections, core boxes, and pattern contours, using hand or pneumatic ramming tools.

- Experienced in packing sand into mold sections, core boxes and pattern contours.

5. Sift

- Sift and pack sand into mold sections Clean and smooth molds to company standards Refractory/ Kiln knowledge

- Sift and pack sand into mold sections, core boxes, and pattern contours, using hand or pneumatic ramming tools.

6. Fork Trucks

- conduct basic maintenance on galin,propane, electric, and diesel fork trucks.

Choose from 10+ customizable core maker resume templates

Build a professional core maker resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your core maker resume.7. Facilitate Removal

- Dusted parting sand over inside of core box to facilitate removal of finished core.

- Sprinkle or spray parting agents onto patterns and mold sections to facilitate removal of patterns from molds.

8. Foundry

- Worked as a core maker in the foundry using chemically treated sand to prepare molds for production of railroad chassis.

- Core maker (8 years), make and assemble cores for molds in the foundry operation.

9. Sand Cores

- Make or form wax or sand cores or molds used in the production of metal castings in foundries.

- Make sand cores used in molds to facilitate the production of carbon and low alloy steel castings.

10. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Organized and produced material inventory as a result of communicating with staff, production ran smoothly.

- Program machine to its specific instructions written on process sheets for the jobs being ran.

11. Core Machine

- Core Maker duties: set up and program machines, regulate heat of core machines, make and inspect cores

- Maintain and operate the following equipment: CB18, UB180, Shalco315, and Sand Core machines

12. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Worked as a team in an assembly line, in a demanding fast-pace environment.

- Schedule jobs according to priority and set up assembly line.

13. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Worked in grinding department salvaging seal ring as well as looking for defects not suitable for shipment per quality standards.

- Painted wicker baskets and ensured each finished product met quality standards.

14. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Developed and documented operating procedures for CNC machines along with MasterCam CAD/CAM programming interface.

- Created material recycling program that recycles waste CNC material and waste additive manufacturing material.

What skills help Core Makers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of core maker skills to add to your resume

The most important skills for a core maker resume and required skills for a core maker to have include:

- Hand Tools

- Sand Molds

- Aluminum Castings

- Core Boxes

- Sift

- Fork Trucks

- Facilitate Removal

- Foundry

- Sand Cores

- RAN

- Core Machine

- Assembly Line

- Quality Standards

- CNC

Updated January 8, 2025