What does a die setter do?

In manufacturing facilities, a die setter is primarily in charge of setting up machines and equipment, selecting and utilizing various tools, preparing molds, gathering measurements and analyzing data, keeping records, monitoring the operations of machinery, and processing products according to protocols. They may also conduct regular maintenance checks, troubleshoot errors, perform basic repairs or adjustments, and produce regular reports for managers. Moreover, a die setter usually works in a team setting, which requires an open and transparent communication line for an efficient workflow.

Die setter responsibilities

Here are examples of responsibilities from real die setter resumes:

- Manage utilization of LOTO procedures, GMP standards and OSHA safety standards.

- Preheat die sections using torches.

- Set up and load programs for CNC horizontal punching presses.

- Set up and repair machines and run hi-low equipment .!

- Clean out grinders, dryers and hoppers for material change over.

- Check, record, and enter data into computer for SPC control.

- Experience working on and operating thermalators, dryers, and hydraulic Cinpresses.

- Supervise employees who run the line to make sure line run efficiently.

- Maintain all PPE requirements and assure everyone else is maintaining safety protocols.

- Maintain ISO standards of the products and ensure proper handling of inspection tools.

- Interpret job specifications, parts solving, operator instructions and SPC control charts.

- Set up machines with resin materials (Iso and Poly) to run production products.

- Fabricate, modify, and remove various types of casts and splints, both plaster and synthetic.

- Verify alignment of work piece on machine, using measuring instruments, such as rules, gauges, and calipers.

- Assist physicians and nursing personnel with orthopedic casting procedures including the application and removal of a variety of casts and splints.

Die setter skills and personality traits

We calculated that 16% of Die Setters are proficient in Die-Setter, Calipers, and Overhead Cranes. They’re also known for soft skills such as Computer skills, Dexterity, and Mechanical skills.

We break down the percentage of Die Setters that have these skills listed on their resume here:

- Die-Setter, 16%

Operated powder metal presses -Inspected and ran tests on parts manufactured by the company - Die-setter set up and tore down presses

- Calipers, 10%

Use Micrometers, Dial indicators, Taper gauges, and Calipers to inspect and certify parts made are good.

- Overhead Cranes, 7%

Install molds in plastic injection presses using 15, 25 & 40 ton overhead cranes.

- Cranes, 6%

Use of overhead crane to move and set dies depending on the current press runs.

- Safety Glasses, 6%

Have my own tools, safety glasses, steel toe work boots, generic shop uniforms.

- Plastic Injection, 6%

Set up, adjusted and maintained equipment with responsibility for production and quality on plastic injection machines.

Most die setters use their skills in "die-setter," "calipers," and "overhead cranes" to do their jobs. You can find more detail on essential die setter responsibilities here:

Computer skills. The most essential soft skill for a die setter to carry out their responsibilities is computer skills. This skill is important for the role because "metal and plastic machine workers must be able to use programmable devices, computers, and robots on the factory floor." Additionally, a die setter resume shows how their duties depend on computer skills: "set up press from blueprint specification for size, weight, concentricity and density using hand tools and computers. "

Mechanical skills. die setters are also known for mechanical skills, which are critical to their duties. You can see how this skill relates to die setter responsibilities, because "these workers must be comfortable with machines and have a good understanding of how all the parts work." A die setter resume example shows how mechanical skills is used in the workplace: "experience with 700 to 1650 ton minster mechanical presses, hi-lo & overhead crane experience, on call duties as needed. "

Physical strength. A big part of what die setters do relies on "physical strength." You can see how essential it is to die setter responsibilities because "metal and plastic machine workers must be able to secure and tighten heavy fixtures into place." Here's an example of how this skill is used from a resume that represents typical die setter tasks: "perform visual and physical inspection using tools such as micrometers, calipers, and gages. "

The three companies that hire the most die setters are:

- Goodman Manufacturing20 die setters jobs

- Schaller Group

5 die setters jobs

- Martinrea International4 die setters jobs

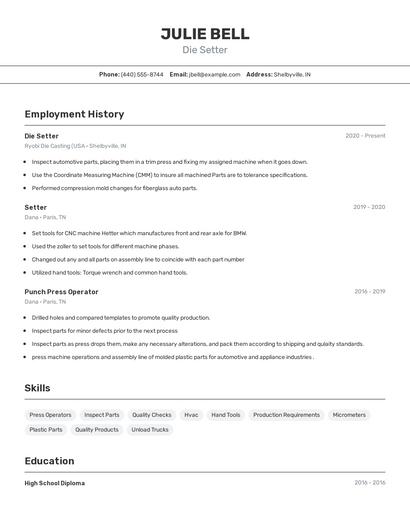

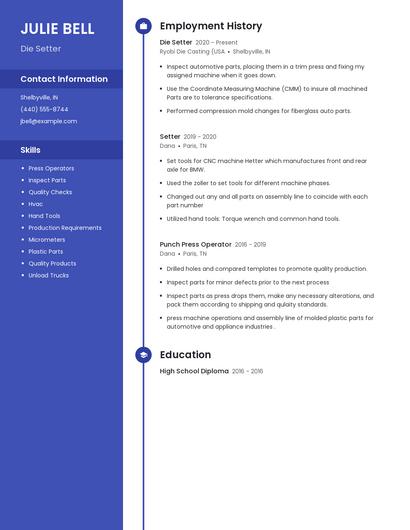

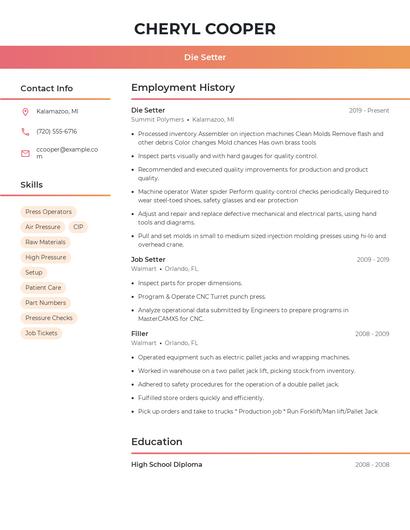

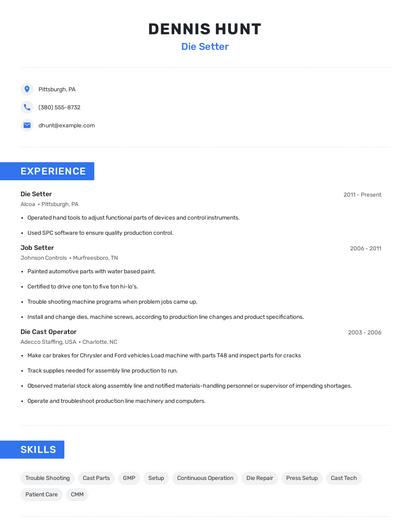

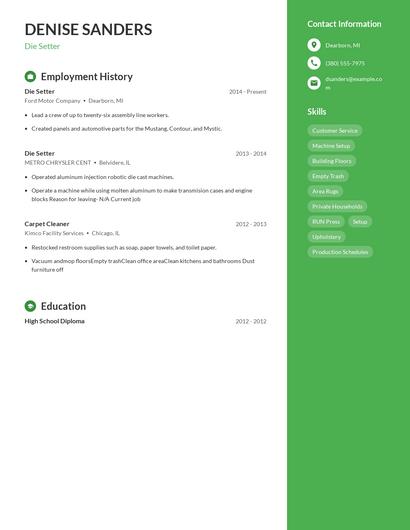

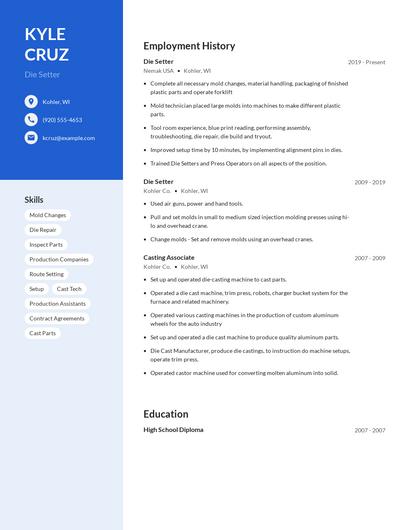

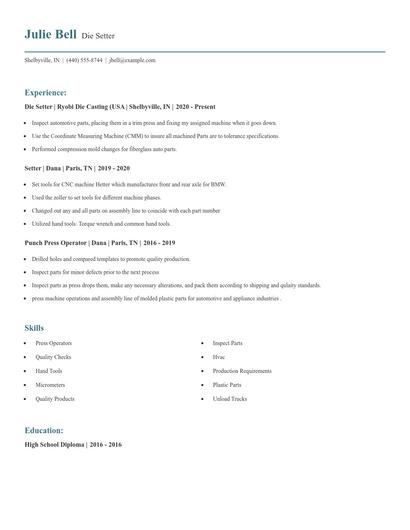

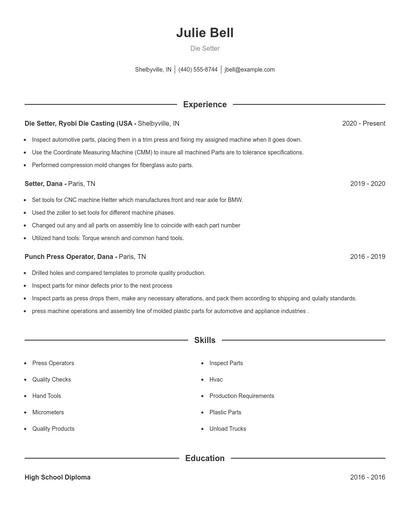

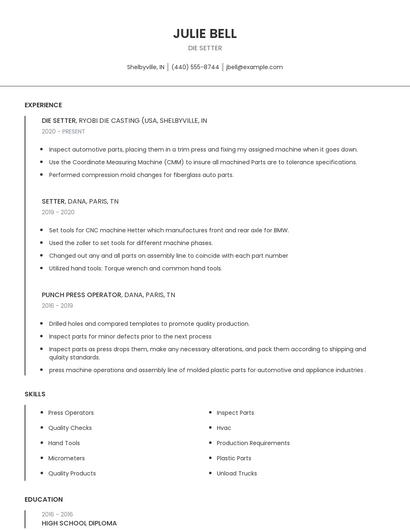

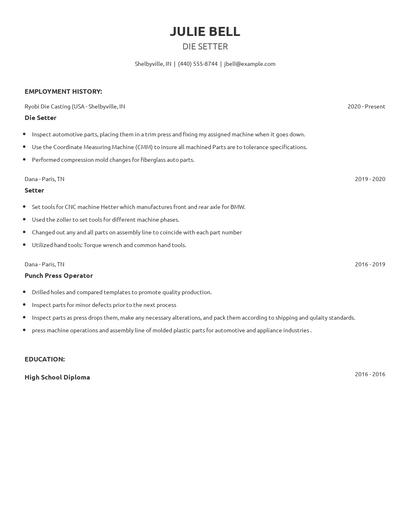

Choose from 10+ customizable die setter resume templates

Build a professional die setter resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your die setter resume.Compare different die setters

Die setter vs. Injection molding technician

Usually working at manufacturing facilities, an injection molding technician is in charge of setting up and designing molds and cores to ensure a smooth workflow and quality standard products. They perform installations and adjustments, troubleshoot problems, monitor systems and regulation parameters, and maintain an active communication line with co-workers. They must also conduct regular maintenance checks and perform repairs as needed. Moreover, an injection molding technician must provide technical support to staff while enforcing and promoting the company's safety policies and regulations.

While similarities exist, there are also some differences between die setters and injection molding technician. For instance, die setter responsibilities require skills such as "die-setter," "overhead cranes," "safety glasses," and "machine operation." Whereas a injection molding technician is skilled in "auxiliary equipment," "osha," "grinders," and "mold maintenance." This is part of what separates the two careers.

Injection molding technicians really shine in the automotive industry with an average salary of $54,624. Comparatively, die setters tend to make the most money in the manufacturing industry with an average salary of $39,473.The education levels that injection molding technicians earn slightly differ from die setters. In particular, injection molding technicians are 1.6% more likely to graduate with a Master's Degree than a die setter. Additionally, they're 0.0% less likely to earn a Doctoral Degree.Die setter vs. Molding technician

A Molding Technician specializes in molding materials such as plastic or metal. They are responsible for operating and calibrating machinery, adhering to product guidelines, conducting quality inspections on finished products, lifting heavy materials, and training new workforce members. There are also instances where they must troubleshoot equipment problems, perform basic repairs, coordinate with managers or engineers, and conduct regular maintenance checks. Molding Technicians must maintain an active communication line with staff while adhering to its safety policies and regulations.

In addition to the difference in salary, there are some other key differences worth noting. For example, die setter responsibilities are more likely to require skills like "die-setter," "calipers," "cranes," and "safety glasses." Meanwhile, a molding technician has duties that require skills in areas such as "auxiliary equipment," "math," "basic math," and "lean manufacturing." These differences highlight just how different the day-to-day in each role looks.

On average, molding technicians earn a higher salary than die setters. Some industries support higher salaries in each profession. Interestingly enough, molding technicians earn the most pay in the health care industry with an average salary of $44,313. Whereas die setters have higher pay in the manufacturing industry, with an average salary of $39,473.In general, molding technicians achieve similar levels of education than die setters. They're 0.0% more likely to obtain a Master's Degree while being 0.0% more likely to earn a Doctoral Degree.Die setter vs. Molder operator

A molder operator sets up for the production of millwork, which is a crucial and major output of precision wood products. This position requires experience with all machinery associated with the woodworking industry. The responsibilities of a molder operator include setting up and operating the molder, inspecting the stock being cut, and verifying the dimensions of cut material to ensure they match specifications.

The required skills of the two careers differ considerably. For example, die setters are more likely to have skills like "die-setter," "calipers," "overhead cranes," and "cranes." But a molder operator is more likely to have skills like "gmp," "dexterity," "troubleshoot," and "basic math."

Molder operators earn the best pay in the manufacturing industry, where they command an average salary of $33,149. Die setters earn the highest pay from the manufacturing industry, with an average salary of $39,473.Most molder operators achieve a similar degree level compared to die setters. For example, they're 0.0% less likely to graduate with a Master's Degree, and 0.1% less likely to earn a Doctoral Degree.Die setter vs. Blow mold operator

Types of die setter

Updated January 8, 2025