Automatically apply for jobs with Zippia

Upload your resume to get started.

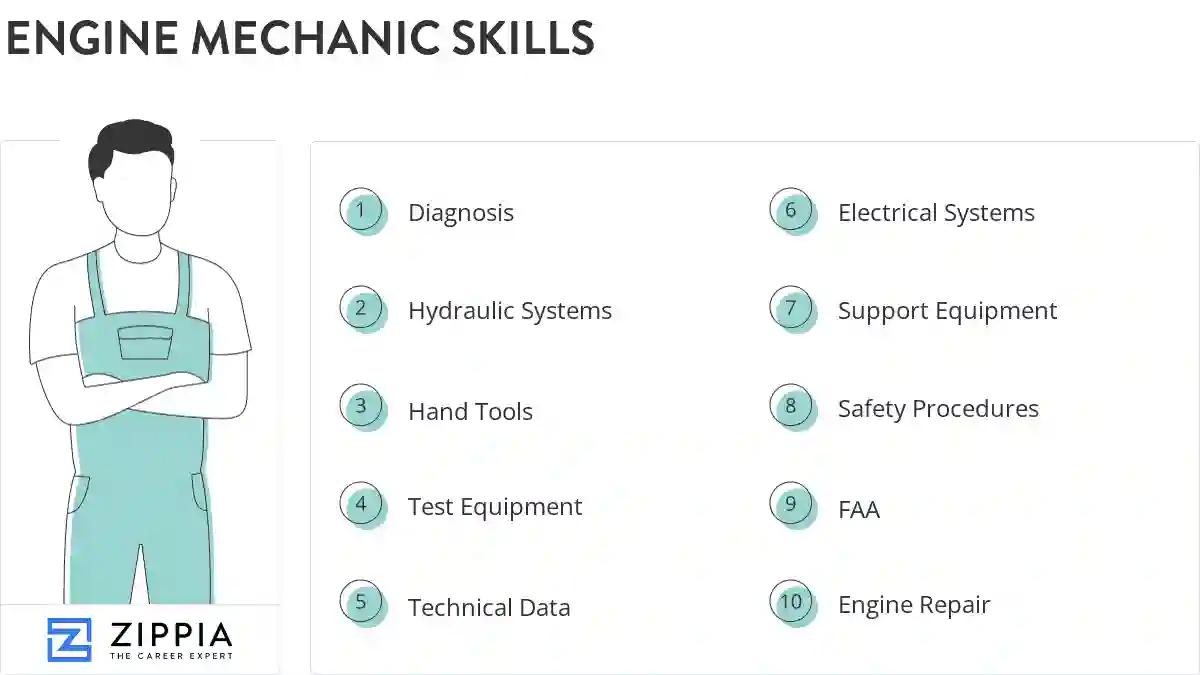

Engine mechanic skills for your resume and career

15 engine mechanic skills for your resume and career

1. Diagnosis

- Worked in there fleet department repairing and diagnosis on all emergency apparatuses and ambulances and police vehicles also included maintenance schedules.

- General automobile maintenance including: vehicle alignments, brake replacement and adjustments, defective parts replacements, problem diagnosis.

2. Hydraulic Systems

- Inspected and overhauled pneumatic and hydraulic systems.

- Performed appropriate maintenance techniques to correct malfunctions in mechanical, electrical and hydraulic systems or components.

3. Hand Tools

- Examine protective guards, loose bolts, and specified safety devices on trucks, and makes adjustments, using hand tools.

- Change battery and recharge batteries and replace transmissions other parts, using hand tools.

4. Test Equipment

Test equipment is a mechanical tool or a device which is used create signals and gather response from an electronic device under test. It helps in detecting any faults in the device and it also proves the proper operation of the electronic device.

- Perform trouble shooting, adjustment and vibration analyses using calibrated test equipment.

- Performed engine test runs, utilizing test equipment to find malfunctions.

5. Technical Data

Technical data refers to both scientific and technical nature and information recorded and presented in any form other than financial and management information but includes manuals and instructional materials, as well as technical data formatted as a computer database.

- Verify all work performed and that the parts/components installed conform to technical data requirements by stamp certifying process documents/historical records.

- Disassemble and assemble gearboxes and accessory drive components per technical data.

6. Electrical Systems

- Perform repair of automobiles such as engines, drive trains, transmissions, electrical systems.

- Use Volt-Ohm Meter to test and troubleshoot electrical systems associated with Turbine engine malfunctions.

Choose from 10+ customizable engine mechanic resume templates

Build a professional engine mechanic resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your engine mechanic resume.7. Support Equipment

- Worked under supervision to perform scheduled and unscheduled maintenance on T-64-GEengines, support equipment and dynamic components.

- Performed preventive and corrective maintenance on aviation ground support equipment, mobile firefighting units, and material-handling, and moving units.

8. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Insured all personnel follow TM safety procedures when operating and maintaining equipment to ensure individual objectives and safety goals are satisfied.

- Sound knowledge of compliance requirements related to International Civil Aviation Organization (ICAO) regulations and safety procedures during construction.

9. FAA

FAA (Federal Aviation Administration) is an aviation regulatory body in the USA.

- Provide engine and component configuration control utilizing customer build standard and FAA Service Bulletin.

- Maintained and recorded necessary paperwork in accordance with FAA and Army regulations for turbine engine maintenance.

10. Engine Repair

- Mentored 12 personnel in engine repair and administrative procedures; resulted in all 12 personnel achieving their qualification within 4 months.

- Experience and extensive training in aircraft maintenance, turbine engine repair and servicing, task prioritization and documentation.

11. Dial Indicators

- Have had some use with dial indicators.

12. Torque Wrenches

A torque wrench is an advanced mechanical tool used to apply a specific torque on a nut/bolt. They can also measure the torque needed to fasten a nut. Torque wrenches are handy in repairs, tire changing, and other manufacturing applications. They are precise and can provide the exact torque required by a vehicle or machine in the automotive or restoration industry. They are safer to use and offer better grip and smoother mechanics than a standard wrench.

- Use of torque wrenches, measuring devices, calibration tools, ignition tester, air flow and vacuum carts.

- Use of specific measuring tools such as depth gauges, calipers, torque wrenches and filler gages on reassembly.

13. Aircraft Engines

- Performed operational tune-ups of new or overhauled aircraft engines.

- General preventive maintenance aircraft engines.

14. Technical Manuals

Technical Manuals are informative pieces of writing, often including diagrams and images, which educate the person who is using it and assist them in learning how to control, build, fix, or otherwise handle the product or products which it speaks of. A technical manual is also known more commonly as a user manual and it typically comes with most products, especially items such as furniture, electronics, appliances, software, machinery, and even medication and medical devices.

- Ensured the proper maintenance procedures by utilizing schematics, technical manuals and electronic maintenance manuals.

- Utilize technical manuals and other publications to solve problems and interpret specification requirements.

15. Repair Procedures

- Read and interpreted drawings, schematics, wiring diagrams, and technical instructions to determine repair procedures.

- Advised, performed, and analyzed various data to determine the repair procedures on aircraft engines.

5 Engine Mechanic resume examples

Build a professional engine mechanic resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your engine mechanic resume.

What skills help Engine Mechanics find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of engine mechanic skills to add to your resume

The most important skills for an engine mechanic resume and required skills for an engine mechanic to have include:

- Diagnosis

- Hydraulic Systems

- Hand Tools

- Test Equipment

- Technical Data

- Electrical Systems

- Support Equipment

- Safety Procedures

- FAA

- Engine Repair

- Dial Indicators

- Torque Wrenches

- Aircraft Engines

- Technical Manuals

- Repair Procedures

- General Maintenance

- Aircraft Maintenance

- Routine Maintenance

- Unscheduled Maintenance

- Gearboxes

- Technical Publications

- Airframe

- Turbine Engines

- Diesel Engines

- Maintenance Actions

- FOD

- Engine Components

- Maintenance Manuals

- Gas Turbine Engines

- Blowers

- Perform Routine Maintenance

- Fall Protection

- Flight Line

- Landing Gear

- Fuel Pumps

- Test Cell

- Engine Maintenance

- APU

- F-16

- Engine Modules

- Engine Performance

- Fuel Systems

- Hazardous Materials

- Engine Assembly

- QEC

- Water Pumps

- Depot

Updated January 8, 2025