What does an engineer, foundry process do?

Engineer, foundry process responsibilities

Here are examples of responsibilities from real engineer, foundry process resumes:

- Lead and assist maintenance in resolving equipment malfunctions, troubleshoot process problems, and organize and implement preventative maintenance procedures.

- Develop a method to get AutoCad isometric drawings relevant to relief valve transferred electronically to the relief valve sizing package.

- Systemize the Deviation/CAPA and train on investigations utilizing DMAIC.

Engineer, foundry process skills and personality traits

We calculated that 23% of Engineers, Foundry Process are proficient in RF, Lean Manufacturing, and CAD. They’re also known for soft skills such as Speaking skills, Writing skills, and Creativity.

We break down the percentage of Engineers, Foundry Process that have these skills listed on their resume here:

- RF, 23%

Improved product yields by >30% optimizing RF sputter etch at various FEOL and BEOL PVD/CVD processes.

- Lean Manufacturing, 15%

Develop process control activities throughout the casting operations using Lean Manufacturing principles.

- CAD, 11%

Gained significant increases in cost-effectiveness and improved manufacturing process efficiency by using 3D CAD to design customized in-house tooling.

- Failure Analysis, 9%

Performed failure analysis on product and purchased equipment - determined cause and product liability and or recommend specification revision.

- Process Changes, 9%

Provided training to manufacturing leads and production personnel on process changes and improvements, and utilization of new automated drilling machine.

- DOE, 6%

Provided technical expertise in setting up, executing and analyzing designed experiments (DOE) in manufacturing environment.

Most engineers, foundry process use their skills in "rf," "lean manufacturing," and "cad" to do their jobs. You can find more detail on essential engineer, foundry process responsibilities here:

Speaking skills. The most essential soft skill for an engineer, foundry process to carry out their responsibilities is speaking skills. This skill is important for the role because "industrial engineers sometimes have to explain their instructions to production staff or technicians before they can make written instructions available." Additionally, an engineer, foundry process resume shows how their duties depend on speaking skills: "identified and addressed process issues resulting in increased shop production. "

Writing skills. Many engineer, foundry process duties rely on writing skills. "industrial engineers must prepare documentation for other engineers or scientists, or for future reference," so an engineer, foundry process will need this skill often in their role. This resume example is just one of many ways engineer, foundry process responsibilities rely on writing skills: "contract position) responsibilities and accomplishments writing iq / oq / pq qualifications and execution of same. "

Creativity. Another skill that relates to the job responsibilities of engineers, foundry process is creativity. This skill is critical to many everyday engineer, foundry process duties, as "industrial engineers use creativity and ingenuity to design new production processes in many kinds of settings in order to reduce the use of material resources, time, or labor while accomplishing the same goal." This example from a resume shows how this skill is used: "identified cost reduction opportunities through better inventory management and supply chain tracking. "

Listening skills. For certain engineer, foundry process responsibilities to be completed, the job requires competence in "listening skills." The day-to-day duties of an engineer, foundry process rely on this skill, as "these engineers often operate in teams, but they also must solicit feedback from customers, vendors, and production staff." For example, this snippet was taken directly from a resume about how this skill applies to what engineers, foundry process do: "communicated quality issues with venders that have arisen on the assembly line. "

Math skills. Another crucial skill for an engineer, foundry process to carry out their responsibilities is "math skills." A big part of what engineers, foundry process relies on this skill, since "industrial engineers use the principles of calculus, trigonometry, and other advanced topics in mathematics for analysis, design, and troubleshooting in their work." How this skill relates to engineer, foundry process duties can be seen in an example from an engineer, foundry process resume snippet: "completed quantitative analysis through data gathering, interviews and observations to document current work flow and identify areas of process improvement. "

Problem-solving skills. While "problem-solving skills" is last on this skills list, don't underestimate its importance to engineer, foundry process responsibilities. Much of what an engineer, foundry process does relies on this skill, seeing as "in designing facilities for manufacturing and processes for providing services, these engineers deal with several issues at once, from workers’ safety to quality assurance." Here is a resume example of how this skill is used in the everyday duties of engineers, foundry process: "conduct statistic data analysis on key quality measures, identifying improvements and delivery of appropriate solutions. "

The three companies that hire the most engineer, foundry processs are:

- Intel6 engineers, foundry process jobs

- Waupaca Foundry5 engineers, foundry process jobs

- Hitachi U.S.A.4 engineers, foundry process jobs

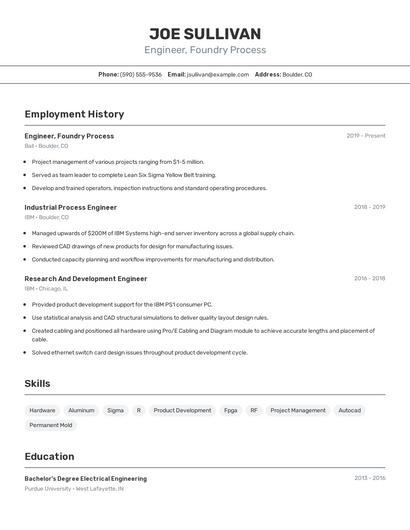

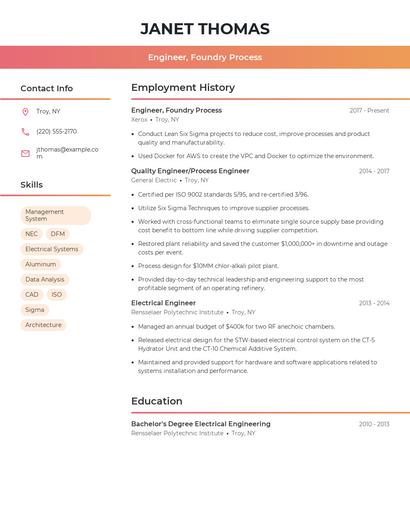

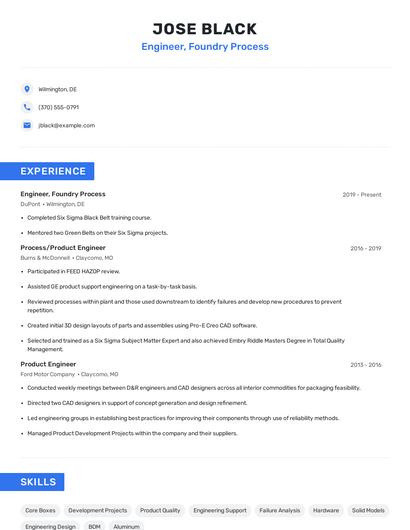

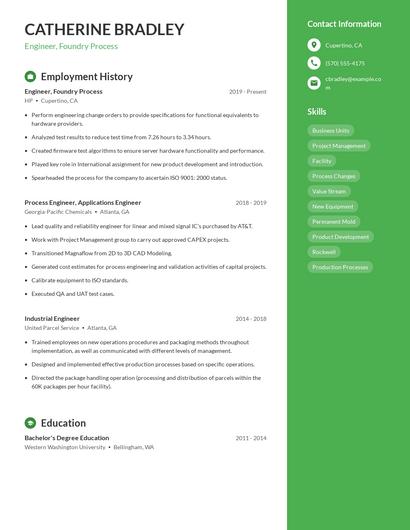

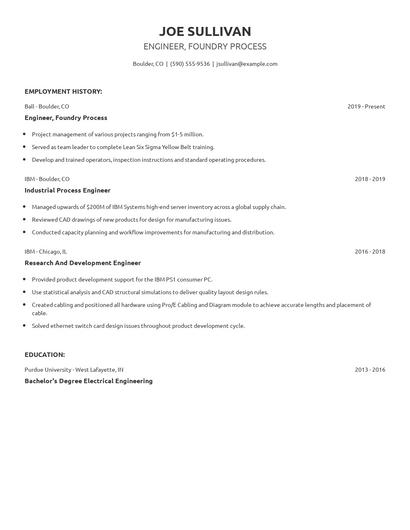

Choose from 10+ customizable engineer, foundry process resume templates

Build a professional engineer, foundry process resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your engineer, foundry process resume.Compare different engineers, foundry process

Engineer, foundry process vs. Process improvement engineer

A process improvement engineer specializes in conducting research and analysis to develop new strategies and ideas to improve the processes in a manufacturing plant or a similar setting. They prioritize efficiency and profitability. Most of the time, engineers participate in a series of meetings where they coordinate with fellow engineers to determine opportunities for product growth and development. Moreover, a process improvement engineer is also responsible for crafting new policies and regulations, upgrading systems, and developing new practices to ensure product quality and customer satisfaction.

These skill sets are where the common ground ends though. The responsibilities of an engineer, foundry process are more likely to require skills like "rf," "analog," "cad," and "failure analysis." On the other hand, a job as a process improvement engineer requires skills like "lean six sigma," "project management," "healthcare," and "data analysis." As you can see, what employees do in each career varies considerably.

Process improvement engineers tend to reach higher levels of education than engineers, foundry process. In fact, process improvement engineers are 7.9% more likely to graduate with a Master's Degree and 1.2% more likely to have a Doctoral Degree.Engineer, foundry process vs. Supplier quality engineer

A Supplier Quality Engineer ensures that the supplier's quality standards are in accordance with the requirement of the organization. They also report supplier performance and quality to management.

In addition to the difference in salary, there are some other key differences worth noting. For example, engineer, foundry process responsibilities are more likely to require skills like "rf," "analog," "cad," and "process changes." Meanwhile, a supplier quality engineer has duties that require skills in areas such as "apqp," "gd," "quality system," and "fmea." These differences highlight just how different the day-to-day in each role looks.

In general, supplier quality engineers achieve higher levels of education than engineers, foundry process. They're 6.3% more likely to obtain a Master's Degree while being 1.2% more likely to earn a Doctoral Degree.Engineer, foundry process vs. Quality control engineer

A quality control engineer is responsible for conducting quality assessments for the company's products and services to ensure adherence to federal regulations and quality standards. Quality control engineers recommend strategic methods by analyzing processes and writing test results. They also identify opportunities for more services that meet public demands and market trends, helping the business generate more resources for revenues. A quality control engineer utilizes various software tools and applications to document findings, requiring them to have excellent communication and technical skills.

The required skills of the two careers differ considerably. For example, engineers, foundry process are more likely to have skills like "rf," "lean manufacturing," "analog," and "cad." But a quality control engineer is more likely to have skills like "quality standards," "corrective action," "test procedures," and "management system."

Most quality control engineers achieve a similar degree level compared to engineers, foundry process. For example, they're 2.3% more likely to graduate with a Master's Degree, and 0.9% more likely to earn a Doctoral Degree.Engineer, foundry process vs. Product support engineer

A product support engineer is responsible for resolving technical issues of end-users regarding the products and services offered by the company. Product support engineers conduct troubleshooting operations for system failures and write resolution reports for reference. They also support the product analysts in improving the product's features and processes to prevent the reoccurrence of defects and maintain optimal performance. A product support engineer designs automation procedures and runs multiple diagnostic tests to ensure high-quality outputs and avoid operational delays.

Types of engineer, foundry process

Updated January 8, 2025