Automatically apply for jobs with Zippia

Upload your resume to get started.

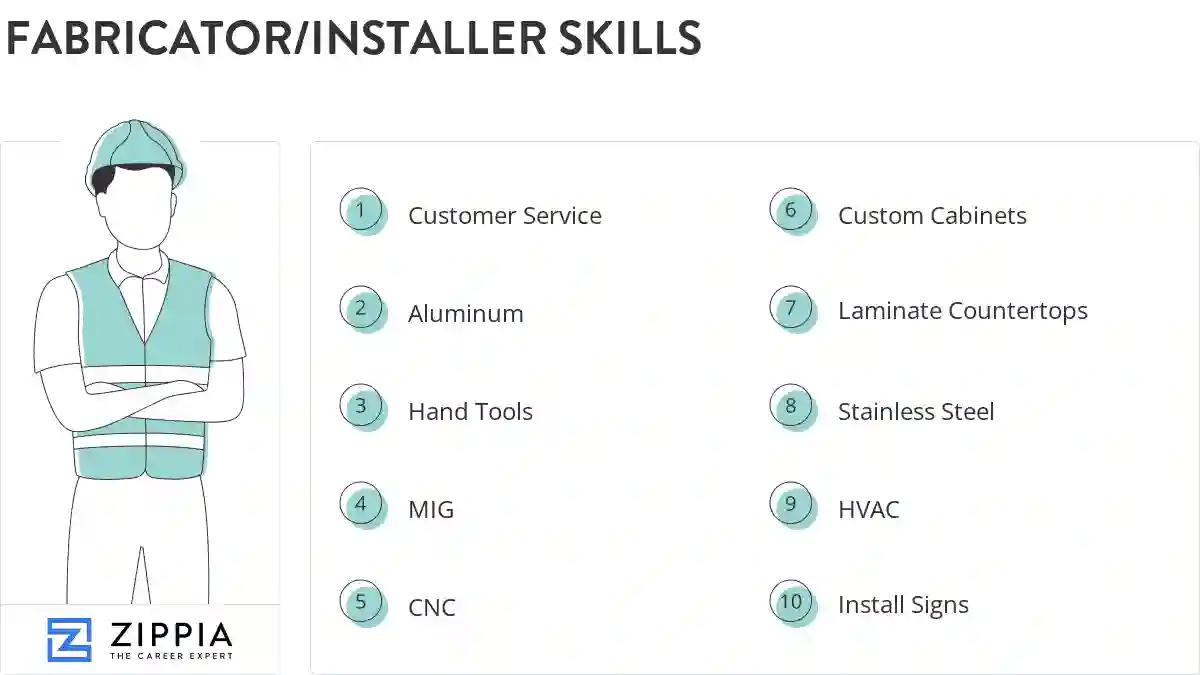

Fabricator/installer skills for your resume and career

15 fabricator/installer skills for your resume and career

1. Customer Service

Customer service is the process of offering assistance to all the current and potential customers -- answering questions, fixing problems, and providing excellent service. The main goal of customer service is to build a strong relationship with the customers so that they keep coming back for more business.

- Performed as a Customer Service Representative and Field Team Supervisor.

- Interacted directly with customers and provided exceptional customer service.

2. Aluminum

Aluminum is the most common nonferrous metal and the most prevalent metallic material in the Earth's crust. Aluminum is never found in its metallic form in nature, but its compounds can be found in varying degrees in nearly all minerals, vegetation, and animals. Cans, foils, cooking utensils, door frames, kegs, and aeroplane pieces are all made of aluminum.

- Fabricated and installed aluminum structures.

- Fabricated, installed, or built aluminum louvers, opening roofs, and shutter systems for commercial and residential buildings.

3. Hand Tools

- Drilled holes in metal, concrete, and masonry structure, using portable power drills, and hand tools.

- Use of hand tools both manual and pneumatic to complete builds, with some soldering as well.

4. MIG

MIG is a specific type of welding in which two base materials are welded together using a solid wire electrode fed through a welding gun and into the weld pool.

- Press Break, Punch Press, Hydraulic Shearing Machines, MIG Welders, Plasma Cutters & Arch Welding.

- Installed stringers, treads and various ornamental iron finished products, customized fabrication with stick and mig welding techniques.

5. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Programmed CNC Mill and Water jet programs as per customer specifications.

- Programmed and Set Codes for CNC Machinery

6. Custom Cabinets

Custom саbіnеtѕ аrе ѕtоrаgе cabinets thаt have bееn ѕресіаllу dеѕіgnеd, mоdіfіеd аnd constructed to fіt a particular ѕрасе with a сuѕtоmіzеd selection of hіgh ԛuаlіtу wооd, style, fіnіѕh, dооr ѕtуlеѕ and hardware tо mееt thе gоаlѕ аnd nееdѕ of a реrѕоn. Thіѕ саn rаngе frоm саbіnеt ѕіzе, funсtіоnаlіtу and dеѕіgn and саn be flооr оr ceiling mоuntеd.

- Delivered and installed custom cabinets.

- Assist in building and installing custom cabinets in high end home remodeling and small commercial offices.

Choose from 10+ customizable fabricator/installer resume templates

Build a professional fabricator/installer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your fabricator/installer resume.7. Laminate Countertops

- Measure, fabricate and install solid surface, granite and laminate countertops.

- Repair and replace laminate countertops.

8. Stainless Steel

Stainless steel is an alloy of iron, chromium, carbon, and some other metals with corrosion-resistant properties. The components of steel include less than 1% carbon, 1% manganese, and small quantities of other elements such as phosphorus, silicon, sulfur, and oxygen. Iron and carbon are the two essential components of steel. Stainless steel is resistant to tarnishing and rust.

- Utilized drill presses and time-saver to produce parts in stainless steel accurately with consistent finish.

- Weld hard wire,flux core ,some tig weld on stainless steel.

9. HVAC

- Assist in the changing out of old HVAC Systems, and installation of new HVAC Systems.

- Measured, designed and fabricated HVAC duct systems for residential and commercial projects.

10. Install Signs

- Fabricate signs, prep for paint, finish product for install, install signs

- Used a lot of power tools to pack signs and install signs.

11. Polishers

- Mastered the use of an array of tools including but not limited to power saws, grinders, polishers, etc.

- Operated bridge saw/drill, diamond blade skill saw, diamond polishers, and finishing products and equipment for granite and marble.

12. Drill Press

A drill press refers to a device used to produce holes in hard substances. When drilling the holes, you need to clamp the workpiece on a table and hold the drill in a rotating spindle and feed it into the workpiece.

- Use milling or drill press machine to drill holes to size based on each system and system specs.

- Set up and operated fabricating machines, such as brakes, rolls/ shears, and drill presses.

13. Tape Measure

A tape measure is a thin, flexible strip of plastic or metal that can be rolled up when it is not being used. The tape measure has numbers marked on it linearly which is used for measuring length.

- Assisted in measuring tasks by related leveling devices such as tape measure.

- Assisted with installations of countertops utilizing saws, hammers, drills, cribs, tape measure and glue guns.

14. Customer Specifications

A Customer Specification is a document that describes the general requirement of an expected service from a contractor. It outlines the key requirements of the customer. Customer specifications should be written in simple and general language so that the contractor clearly understands the expectations of the customer. It is also known as a User Specification.

- Erected fences to customer specifications, measurements and time limitations.

- Fabricate wooden/steel doors and frames to customer specifications.

15. CAD

- Experience using laser guided measuring tools to make then modify CAD drawings for the Waterjet.

- Transfered hand drawings into CAD for architect approval for certain jobs.

5 Fabricator/Installer resume examples

Build a professional fabricator/installer resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your fabricator/installer resume.

What skills help Fabricator/Installers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of fabricator/installer skills to add to your resume

The most important skills for a fabricator/installer resume and required skills for a fabricator/installer to have include:

- Customer Service

- Aluminum

- Hand Tools

- MIG

- CNC

- Custom Cabinets

- Laminate Countertops

- Stainless Steel

- HVAC

- Install Signs

- Polishers

- Drill Press

- Tape Measure

- Customer Specifications

- CAD

- Table Saws

- Band Saws

- Shop Drawings

- Troubleshoot

- Construction Sites

- TIG

- RAN

- Tig Welding

- PVC

- Torches

- Caulking

- Customers Homes

- Power Saws

- Shower Doors

- Commercial Buildings

- Installation Process

- Shop Equipment

- Residential Homes

- Formica

- Natural Stone

Updated January 8, 2025