Automatically apply for jobs with Zippia

Upload your resume to get started.

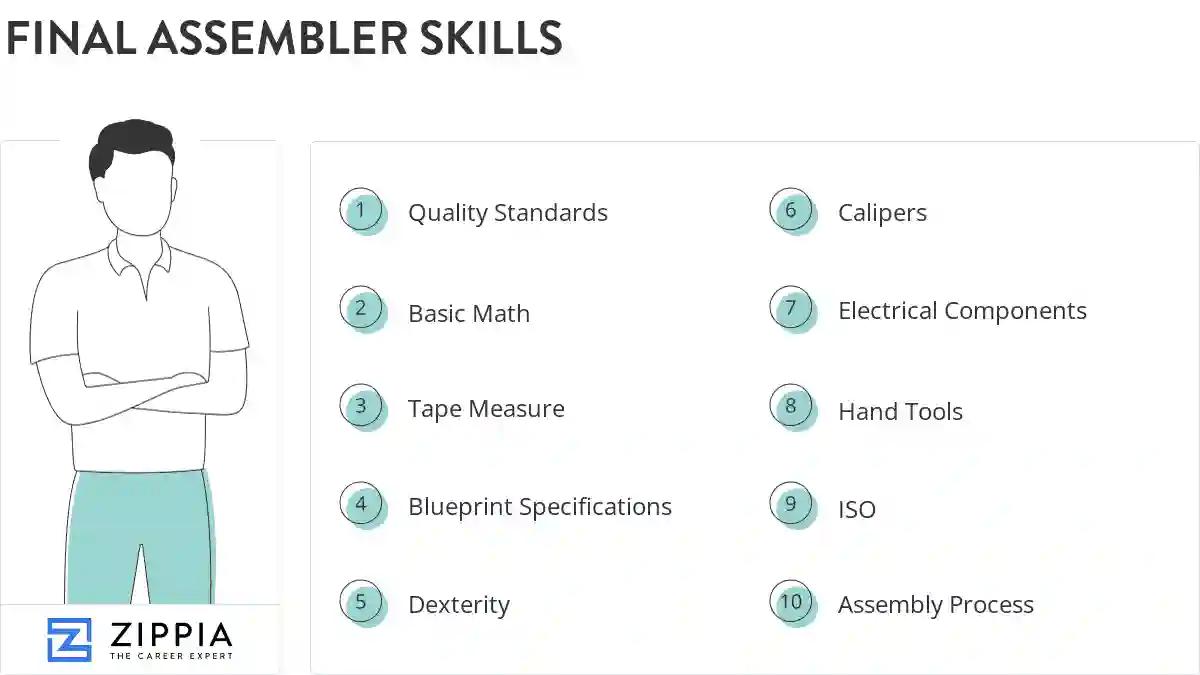

Final assembler skills for your resume and career

15 final assembler skills for your resume and career

1. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Washed, transported, tracked parts based on blueprints and quality standards set by the company.

- Determine quality issues and set aside defective material within Company s quality standards.

2. Basic Math

- Read tape measure/ basic math-Read blueprints-Assembly of boxes

- Total quality control, reach daily goal, assemble shower valves, basic mathematics, teamwork, keep work area clean.

3. Tape Measure

A tape measure is a thin, flexible strip of plastic or metal that can be rolled up when it is not being used. The tape measure has numbers marked on it linearly which is used for measuring length.

- Air tools, tape measure, putty knife.

- Put awnings together worked about 72 hours a week it was a temporary job worked with drills tape measures hammers and etc

4. Blueprint Specifications

Blueprints are layouts or designs about the construction of a building or structure. It consists of accurate engineering drawing on light-sensitive sheets allowing to create copies easily.

- Follow written instructions and read and apply blueprint specifications.-Check parts for conformance to specifications.

- Make setups and adjustments holding tolerances to blueprint specifications.

5. Dexterity

- Performed various assembly, sub-assembly, and or packaging operation in a production area requiring general physical dexterity.

- Demonstrated manual dexterity as it relates to detailed assembly processes.

6. Calipers

- Measure parts using gauges and calipers* Recording the numbers and entering them into SPC database.

- Re-manufactured and packaged disc brake calipers for Napa Auto Parts.

Choose from 10+ customizable final assembler resume templates

Build a professional final assembler resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your final assembler resume.7. Electrical Components

- Removed and replaced mechanical and electrical components.

- Installed small electrical components, inspected, tested and packaged final product.

8. Hand Tools

- Utilized various hand tools, electronic testing equipment, power, and air tools to complete the assembly process.

- Use of power hand tools and pneumatic air tools to drill holes using templates, soldering, wiring assembly.

9. ISO

- Inspected prototypes products to ensure conformity to specifications using ISO 9000 Standards.

- Maintained product documentation, non-conformance records and related inspection logs as required quality management system and ISO 9001 compliance.

10. Assembly Process

- Build and assemble up to 5 or more different types of assembly processes.

- Awarded several citations and monetary compensation for suggestions to improve assembly processes, cut costs and reduce waste.

11. Safety Policies

Safety policies are the rules and codes of conduct developed by an organization to ensure workplace safety.

- Performed all duties according to established company safety policies, including strict adherence to all OSHA guidelines ensuring zero safety violations.

- Observed all safety policies and procedures Recognized and reported defective material and equipment to shift supervisor.

12. Air Tools

- Used additional air tools to assemble components as necessary (drills, tack guns, etc.)

- Mounted painted parts onto unit using various hand and air tools and overhead crane operation.

13. Quality Products

A quality product satisfies the client's intended need and matches the cost the consumer paid for it.

- Comply with Good Manufacturing Training and guarantee quality products by following approved assembly and testing procedure.

- Worked closely with both quality control and management to ensure quality products were sent to the customer.

14. Drill Presses

- Used various power tools, including routers, table saws, drills, band saws, drill presses, power staplers.

- Operated drill presses, screw guns, packagers, and other equipment to assist in assembly operation.

15. Safety Equipment

- Use and assures proper fit of any required safety equipment and clothing.

- Set up and verified the functionality of safety equipment.

5 Final Assembler resume examples

Build a professional final assembler resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your final assembler resume.

What skills help Final Assemblers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of final assembler skills to add to your resume

The most important skills for a final assembler resume and required skills for a final assembler to have include:

- Quality Standards

- Basic Math

- Tape Measure

- Blueprint Specifications

- Dexterity

- Calipers

- Electrical Components

- Hand Tools

- ISO

- Assembly Process

- Safety Policies

- Air Tools

- Quality Products

- Drill Presses

- Safety Equipment

- Band Saws

- Quality Checks

- PPE

- Clips

- Jigs

- Windows

- Safety Guidelines

- Fork Trucks

- Circuit Boards

- Electrical Systems

- RAN

- Control Panels

- Customer Specifications

- Assembly Line

- Control Boxes

- Serial Numbers

- FAA

- Computer System

- Assembly Procedures

- Truck Bodies

- PCB

- SMT

- Dryers

Updated January 8, 2025