What does a flexographic press operator do?

Flexographic press operator responsibilities

Here are examples of responsibilities from real flexographic press operator resumes:

- Operate flexo press machine with intent of minimizing downtime and achieving production goals.

- Manage shop, warehouse & inventories, supervise employees, schedule production, maintain and run equipment when need.

- Load and unload press with screens, inks, flood bars and squeegees.

- Remain current with all ISO revisions; experience with ISO in a work cell environment.

- Transfer custom design artwork to silk-screen medium to be apply to t-shirts and other garments.

- Set up and operate production equipment in accordance with current good manufacturing practices and standard operating procedures.

- Lead a crew of more than six personnel to safely operate and maintain a 108"KBA rotogravure eight-unit printing press.

- Set up includes hanging plates pre-setting ink profiles and conductivity water levels, viscosity of coatings when require.

- Press helper on 40"six color Komori.

Flexographic press operator skills and personality traits

We calculated that 11% of Flexographic Press Operators are proficient in UV, Basic Math, and Flexo. They’re also known for soft skills such as Computer skills, Dexterity, and Mechanical skills.

We break down the percentage of Flexographic Press Operators that have these skills listed on their resume here:

- UV, 11%

Process printing on 6 & 8 color CI presses, solvent based, water based & UV Inks

- Basic Math, 11%

Performed basic mathematical calculations using a calculator.

- Flexo, 9%

Run 2200 and P7 Mark Andy Flexo press

- General Maintenance, 9%

Performed general maintenance work on various machines to ensure production standards were maintained which included preventive electrical maintenance work as well.

- Troubleshoot, 8%

Set up operate and troubleshoot (Mark Andy) printing press.

- Quality Standards, 6%

Ensured high quality for all jobs using quality standards and processes.

Common skills that a flexographic press operator uses to do their job include "uv," "basic math," and "flexo." You can find details on the most important flexographic press operator responsibilities below.

Computer skills. One of the key soft skills for a flexographic press operator to have is computer skills. You can see how this relates to what flexographic press operators do because "metal and plastic machine workers must be able to use programmable devices, computers, and robots on the factory floor." Additionally, a flexographic press operator resume shows how flexographic press operators use computer skills: "general maintenance,safety,and computer functions. "

Mechanical skills. This is an important skill for flexographic press operators to perform their duties. For an example of how flexographic press operator responsibilities depend on this skill, consider that "these workers must be comfortable with machines and have a good understanding of how all the parts work." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a flexographic press operator: "maintain most mechanical problems with press and perform preventive maintenance daily/weekly. ".

Physical strength. flexographic press operator responsibilities often require "physical strength." The duties that rely on this skill are shown by the fact that "metal and plastic machine workers must be able to secure and tighten heavy fixtures into place." This resume example shows what flexographic press operators do with physical strength on a typical day: "performed quality checks to verify weight, strength and durability of the finished goods. "

The three companies that hire the most flexographic press operators are:

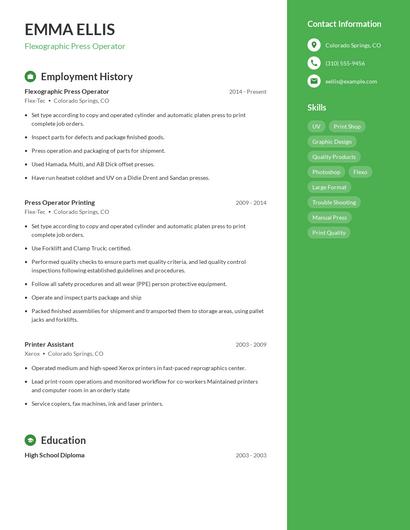

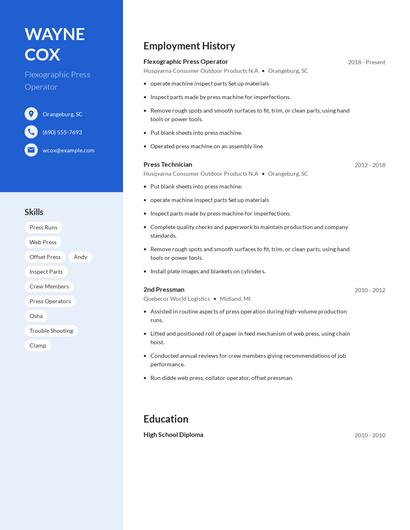

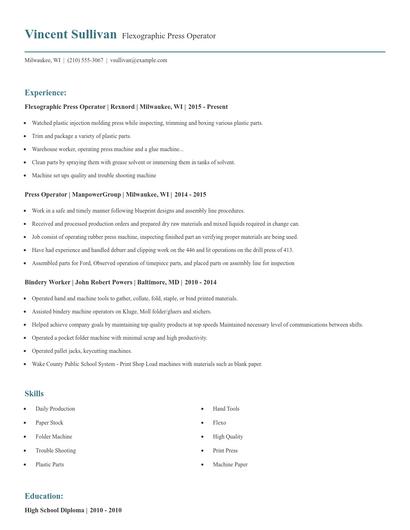

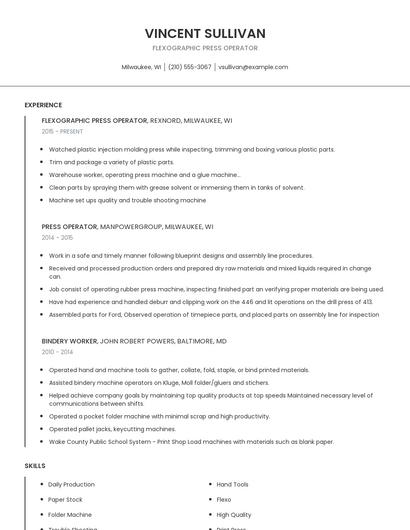

Choose from 10+ customizable flexographic press operator resume templates

Build a professional flexographic press operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your flexographic press operator resume.Compare different flexographic press operators

Flexographic press operator vs. Roll tender

A printer is primarily responsible for printing materials according to project requirements. Although the extent of their responsibilities depends on their company or employment industry, it typically includes identifying the project needs, utilizing machines and tools, cutting materials according to size guidelines, and submitting materials to clients or managers promptly. Moreover, a printer typically works in a team setting, which requires an active communication line for a smooth and efficient workflow.

These skill sets are where the common ground ends though. The responsibilities of a flexographic press operator are more likely to require skills like "uv," "flexo," "general maintenance," and "troubleshoot." On the other hand, a job as a roll tender requires skills like "load paper," "offset printing," "load rolls," and "clean press." As you can see, what employees do in each career varies considerably.

Roll tenders earn the highest salaries when working in the media industry, with an average yearly salary of $36,580. On the other hand, flexographic press operators are paid more in the transportation industry with an average salary of $44,049.roll tenders tend to reach similar levels of education than flexographic press operators. In fact, roll tenders are 1.6% less likely to graduate with a Master's Degree and 0.0% less likely to have a Doctoral Degree.Flexographic press operator vs. Printer

A screen making technician performs installations and repairs to maintain the smooth flow of operations at manufacturing facilities. Their responsibilities typically include conducting measurements and assessments, setting guidelines, troubleshooting problems, gathering and analyzing data, and maintaining records of all procedures and adjustments. They must also maintain an active communication line with co-workers to ensure a safe and efficient work environment. Moreover, a screen making technician provides technical support to different teams while implementing company standards and regulations.

Each career also uses different skills, according to real flexographic press operator resumes. While flexographic press operator responsibilities can utilize skills like "basic math," "flexo," "general maintenance," and "safety standards," printers use skills like "customer service," "data entry," "automatic press," and "clean screens."

In general, printers achieve similar levels of education than flexographic press operators. They're 0.4% less likely to obtain a Master's Degree while being 0.0% more likely to earn a Doctoral Degree.Flexographic press operator vs. Screen making technician

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from flexographic press operator resumes include skills like "uv," "basic math," "flexo," and "troubleshoot," whereas a screen making technician is more likely to list skills in "customer service," "hand tools," "plumbing," and "caulking. "

Screen making technicians make a very good living in the manufacturing industry with an average annual salary of $35,358. On the other hand, flexographic press operators are paid the highest salary in the transportation industry, with average annual pay of $44,049.screen making technicians typically earn similar educational levels compared to flexographic press operators. Specifically, they're 1.1% more likely to graduate with a Master's Degree, and 0.1% more likely to earn a Doctoral Degree.Flexographic press operator vs. Screen printer

Types of flexographic press operator

Updated January 8, 2025