What does a forming machine operator do?

Forming machine operator responsibilities

Here are examples of responsibilities from real forming machine operator resumes:

- Design all extrusion dies and their support tooling.

- Utilize CNC machinery for shaping and routing of materials for final product.

- Trouble shooting CNC programs and re writing programs to edit to meet measurement specification.

- Machine parts according to customer specifications utilizing calipers.

- Work with injection molding manufacturing hospital product parts -operate machines in departments of extrusion and injection molding -Experience with digital calipers.

- Stack pieces onto pallet, strap and then wrap the pallet up and label with customers information for pick up date.

- Monitor machine operation throughout shift; also programme and troubleshot Ishida and Yamato scale.

Forming machine operator skills and personality traits

We calculated that 18% of Forming Machine Operators are proficient in Quality Standards, Safety Rules, and Troubleshoot. They’re also known for soft skills such as Communication skills, Coordination, and Mechanical skills.

We break down the percentage of Forming Machine Operators that have these skills listed on their resume here:

- Quality Standards, 18%

Do quality checks every half hour for high quality standards that meet ISO-9001/2000, ISO-14001.

- Safety Rules, 10%

Observe all safety rules and regulations and is responsible for using required safety equipment.

- Troubleshoot, 7%

Displayed ability to troubleshoot equipment issues to meet productivity standards.

- Tape Measure, 6%

Loaded material onto roller Follow and interpet blueprints maintain quality control and ispection use calipers, tape measurer

- Pallets, 6%

Obtained a pallet jack permit.

- Cranes, 6%

Certified as an overhead crane operator and forklift operator.

"quality standards," "safety rules," and "troubleshoot" are among the most common skills that forming machine operators use at work. You can find even more forming machine operator responsibilities below, including:

Communication skills. The most essential soft skill for a forming machine operator to carry out their responsibilities is communication skills. This skill is important for the role because "material moving machine operators signal and direct workers to load and unload material." Additionally, a forming machine operator resume shows how their duties depend on communication skills: "change machine parts shift reporting and documentation skills used good attention to detail math skills communication skills"

Coordination. Another soft skill that's essential for fulfilling forming machine operator duties is coordination. The role rewards competence in this skill because "material moving machine operators must have steady hands and feet to guide and control heavy machinery precisely." According to a forming machine operator resume, here's how forming machine operators can utilize coordination in their job responsibilities: "speed, quickness, hand eye coordination, use of tape measure and viscosity tester. "

Mechanical skills. This is an important skill for forming machine operators to perform their duties. For an example of how forming machine operator responsibilities depend on this skill, consider that "material moving machine operators make minor adjustments to their machines and perform basic maintenance on them." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a forming machine operator: "operated automatic cnc machines, mechanical and hydraulic presses. ".

Visual ability. A big part of what forming machine operators do relies on "visual ability." You can see how essential it is to forming machine operator responsibilities because "material moving machine operators must be able to see clearly where they are driving or what they are moving." Here's an example of how this skill is used from a resume that represents typical forming machine operator tasks: "operate extrusion & compounding machines visually inspect temperature gages"

The three companies that hire the most forming machine operators are:

- Saint-Gobain4 forming machine operators jobs

- Inline Plastics2 forming machine operators jobs

- AMETEK1 forming machine operators jobs

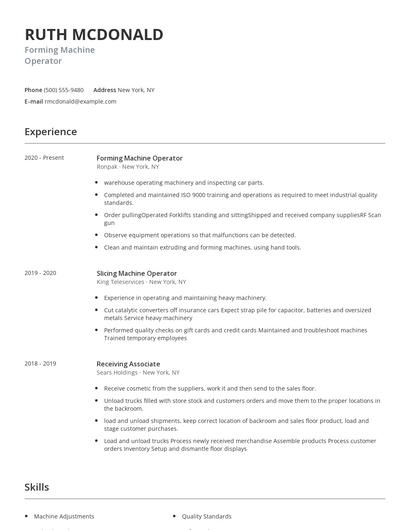

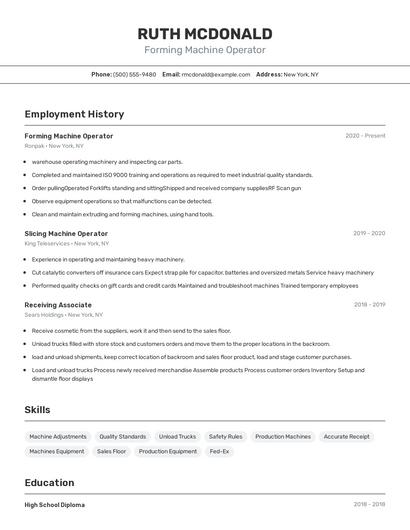

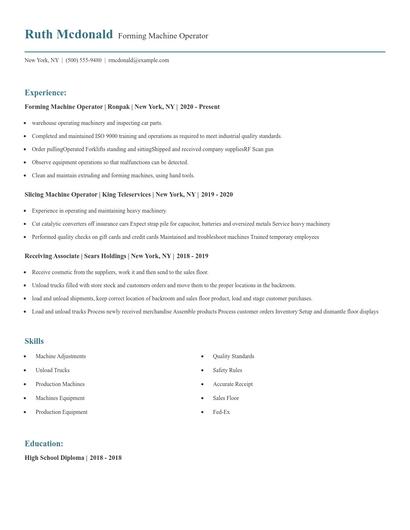

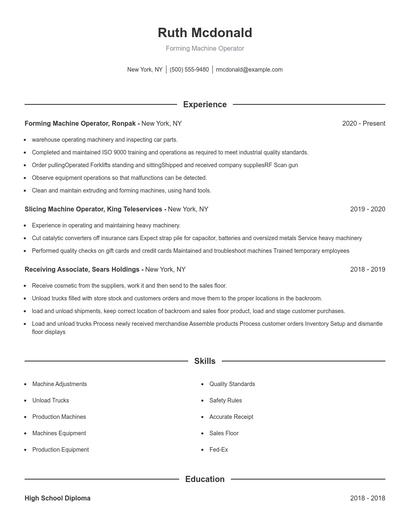

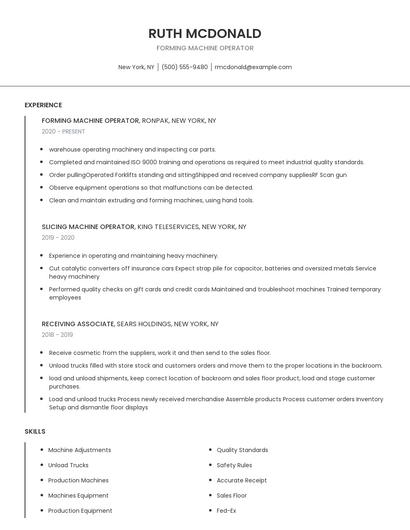

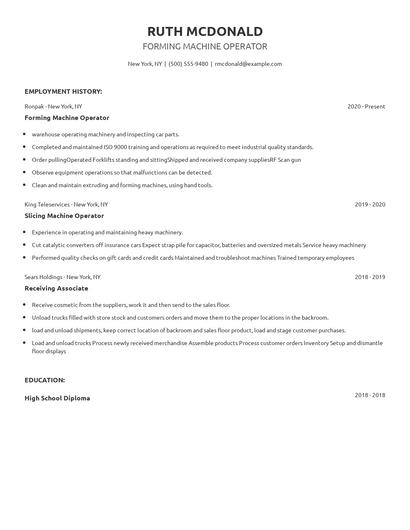

Choose from 10+ customizable forming machine operator resume templates

Build a professional forming machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your forming machine operator resume.Compare different forming machine operators

Forming machine operator vs. Pelletizer operator

Operators are skilled workers who are in charge of working on an industrial machine or a specific aspect of the manufacturing business. They are trained to operate machines, learning how to use them. They are also responsible for the maintenance and repair of the machine, and they should be able to troubleshoot problems and provide remedies to them. They must be knowledgeable about the different parts of the machine and how to mitigate any challenges that may arise. Operators should be alert, detail-oriented, and familiar with safety and health guidelines.

While similarities exist, there are also some differences between forming machine operators and pelletizer operator. For instance, forming machine operator responsibilities require skills such as "quality standards," "safety rules," "troubleshoot," and "grinders." Whereas a pelletizer operator is skilled in "english-spanish," "lab equipment," "control room," and "laboratory analysis." This is part of what separates the two careers.

The education levels that pelletizer operators earn slightly differ from forming machine operators. In particular, pelletizer operators are 9.1% more likely to graduate with a Master's Degree than a forming machine operator. Additionally, they're 0.0% less likely to earn a Doctoral Degree.Forming machine operator vs. Operator

A machine operator/forklift operator is responsible for operating industrial trucks to move merchandise around the warehouse facilities and other assigned areas. Machine operators/forklift operators also assist with inventory tasks by scanning orders and ensuring the correct merchandise for shipment. They manage the stability of the vehicles, ensuring its efficiency and optimization during operations, performing engine repairs for any inconsistencies to avoid delays on deliveries. A machine operator/forklift operator should strictly follow the safety protocols of the business, as well as have knowledge of the mechanical industry.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that forming machine operator responsibilities requires skills like "troubleshoot," "grinders," "tape measure," and "pallets." But an operator might use other skills in their typical duties, such as, "safety procedures," "cdl," "emergency calls," and "preventative maintenance."

Average education levels between the two professions vary. Operators tend to reach similar levels of education than forming machine operators. In fact, they're 1.9% more likely to graduate with a Master's Degree and 0.0% more likely to earn a Doctoral Degree.Forming machine operator vs. Hot end operator

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a forming machine operator is likely to be skilled in "quality standards," "safety rules," "troubleshoot," and "grinders," while a typical hot end operator is skilled in "control room," "chemical application," "hot end," and "fiberglass insulation."

Hot end operators typically earn similar educational levels compared to forming machine operators. Specifically, they're 3.3% more likely to graduate with a Master's Degree, and 0.0% more likely to earn a Doctoral Degree.Forming machine operator vs. Machine operator/forklift operator

Types of forming machine operator

Updated January 8, 2025