What does a general machine operator do?

General machine operator responsibilities

Here are examples of responsibilities from real general machine operator resumes:

- Lift work pieces to machines using hoists.

- Control & troubleshoot automate extrusion line adjusting speed & feed, monitoring temperature, & finish material specification per customers order.

- Overlook daily operations of single/twin screw extruders and packaging of finish product.

General machine operator skills and personality traits

We calculated that 12% of General Machine Operators are proficient in Math, CNC, and Safety Procedures. They’re also known for soft skills such as Communication skills, Coordination, and Visual ability.

We break down the percentage of General Machine Operators that have these skills listed on their resume here:

- Math, 12%

Produced and maintained accurate documentation for production reports using math and computer skills.

- CNC, 10%

Operated and programmed CNC Milling, Plasma Arc and Flame cutting CNC Machinery.

- Safety Procedures, 10%

Maintained a clean and safe work environment by practicing safety procedures.

- Troubleshoot, 9%

Maintain machinery integrity and troubleshoot equipment issues Skills :.

- Production Process, 8%

Worked on or ran 8 different machines, gained understanding of the lumber production process as a whole.

- Machine Operation, 6%

Perform machine operations per specified parameters and Standard Operating Procedures.

"math," "cnc," and "safety procedures" are among the most common skills that general machine operators use at work. You can find even more general machine operator responsibilities below, including:

Communication skills. To carry out their duties, the most important skill for a general machine operator to have is communication skills. Their role and responsibilities require that "material moving machine operators signal and direct workers to load and unload material." General machine operators often use communication skills in their day-to-day job, as shown by this real resume: "generate samples for quality control, break relief employees, follow gmp's, and implement team dynamics with communication. "

Coordination. Another essential skill to perform general machine operator duties is coordination. General machine operators responsibilities require that "material moving machine operators must have steady hands and feet to guide and control heavy machinery precisely." General machine operators also use coordination in their role according to a real resume snippet: "operated production machinery utilized good communication skill to interact well with co-workers possess good hand-eye coordination ability to perform repetitive tasks"

Visual ability. general machine operators are also known for visual ability, which are critical to their duties. You can see how this skill relates to general machine operator responsibilities, because "material moving machine operators must be able to see clearly where they are driving or what they are moving." A general machine operator resume example shows how visual ability is used in the workplace: "performed visual inspections on sensitive production lines. "

The three companies that hire the most general machine operators are:

- Garney Holding Company8 general machine operators jobs

- Cargill7 general machine operators jobs

- Orchid Orthopedic Solutions6 general machine operators jobs

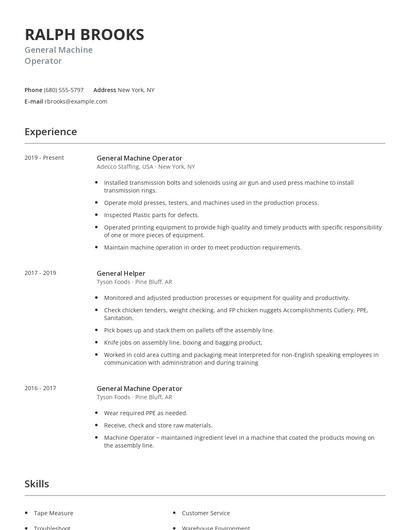

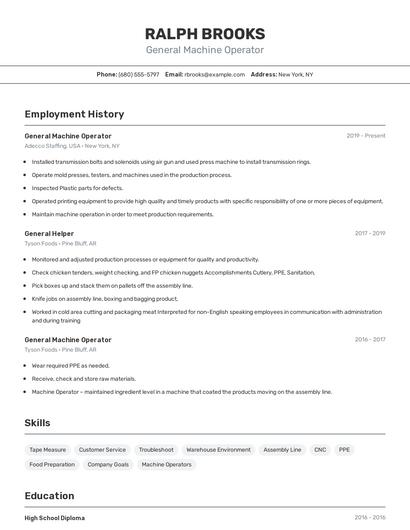

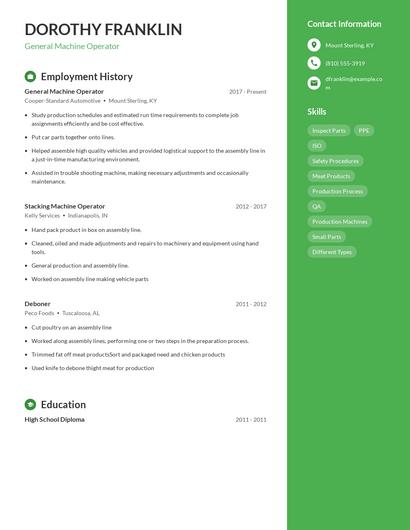

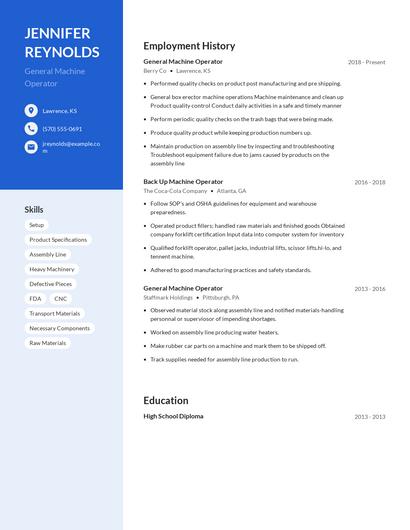

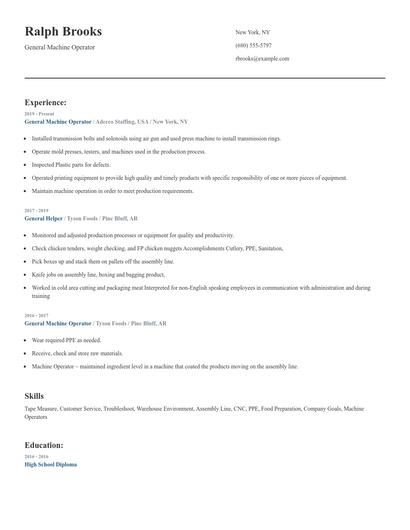

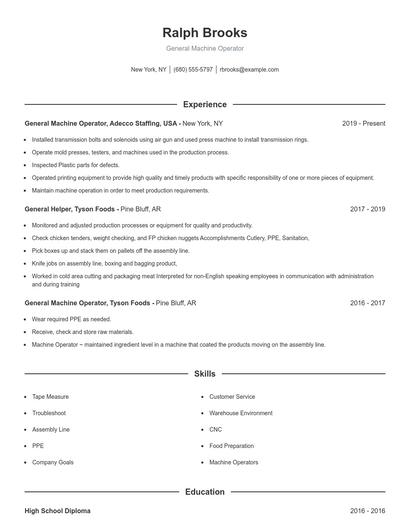

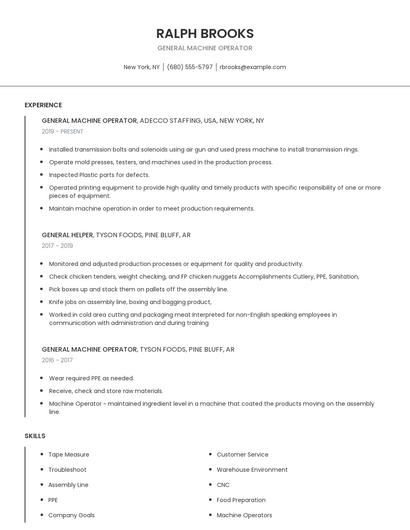

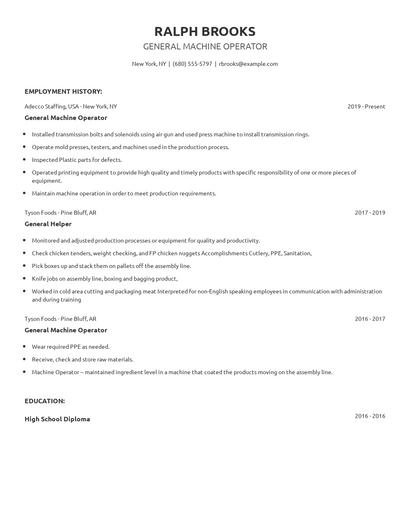

Choose from 10+ customizable general machine operator resume templates

Build a professional general machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your general machine operator resume.Compare different general machine operators

General machine operator vs. Mill operator

Mill operators are skilled employees who are responsible for operating and maintaining milling machines that grind materials such as rocks or chemicals at a milling facility. These operators must gather raw materials for production and assist with the inventory of all materials. They must operate a wide variety of equipment such as power saws, sanders, drill press, and basic hand tools while performing regular maintenance and troubleshooting on the milling machines. Mill operators must also attend safety meetings that are held weekly and monthly to ensure machine operators are following safety procedures.

While similarities exist, there are also some differences between general machine operators and mill operator. For instance, general machine operator responsibilities require skills such as "safety regulations," "product specifications," "assembly line," and "pallet jack." Whereas a mill operator is skilled in "osha," "calipers," "hand tools," and "basic math." This is part of what separates the two careers.

Mill operators really shine in the construction industry with an average salary of $41,320. Comparatively, general machine operators tend to make the most money in the finance industry with an average salary of $35,435.mill operators tend to reach similar levels of education than general machine operators. In fact, mill operators are 0.0% less likely to graduate with a Master's Degree and 0.1% more likely to have a Doctoral Degree.General machine operator vs. Machine operator/forklift operator

A machine operator/forklift operator is responsible for operating industrial trucks to move merchandise around the warehouse facilities and other assigned areas. Machine operators/forklift operators also assist with inventory tasks by scanning orders and ensuring the correct merchandise for shipment. They manage the stability of the vehicles, ensuring its efficiency and optimization during operations, performing engine repairs for any inconsistencies to avoid delays on deliveries. A machine operator/forklift operator should strictly follow the safety protocols of the business, as well as have knowledge of the mechanical industry.

Each career also uses different skills, according to real general machine operator resumes. While general machine operator responsibilities can utilize skills like "math," "production equipment," "safety regulations," and "product specifications," machine operator/forklift operators use skills like "safety standards," "drive forklift," "load trucks," and "electric pallet jack."

Machine operator/forklift operators earn a higher average salary than general machine operators. But machine operator/forklift operators earn the highest pay in the automotive industry, with an average salary of $36,711. Additionally, general machine operators earn the highest salaries in the finance with average pay of $35,435 annually.machine operator/forklift operators earn similar levels of education than general machine operators in general. They're 0.1% less likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.General machine operator vs. Saw operator

Saw operators are responsible for setting up and operating power saws to slot, cut, and trim metallic and non-metallic materials. They are the ones who choose and install blades on machinery using hand-tools and verify dimensions of finished material using measuring devices. They may perform additional tasks such as loading saws and monitoring sawing operations, and replacing damaged or worn saw blades. Saw operators are also responsible for recording data on production reports and assisting staff with the maintenance and repair of saw equipment.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a general machine operator is likely to be skilled in "troubleshoot," "production process," "production equipment," and "ppe," while a typical saw operator is skilled in "hand tools," "basic math," "aluminum," and "overhead cranes."

Saw operators earn the best pay in the construction industry, where they command an average salary of $36,227. General machine operators earn the highest pay from the finance industry, with an average salary of $35,435.Most saw operators achieve a similar degree level compared to general machine operators. For example, they're 0.1% less likely to graduate with a Master's Degree, and 0.1% less likely to earn a Doctoral Degree.General machine operator vs. Relief operator

A relief operator job depends on the institution or organization. Their main jobs include examining, measuring, and weighing materials or products to verify conformance to specifications, using measuring devices such as rulers, micrometers, or scales. Their additional responsibilities include maintaining regular contact and communication with customers to resolve concerns, issues, and complaints.

Even though a few skill sets overlap between general machine operators and relief operators, there are some differences that are important to note. For one, a general machine operator might have more use for skills like "math," "cnc," "troubleshoot," and "machine operation." Meanwhile, some responsibilities of relief operators require skills like "food safety," "cip," "basic math," and "cdl. "

Relief operators enjoy the best pay in the energy industry, with an average salary of $46,955. For comparison, general machine operators earn the highest salary in the finance industry.The average resume of relief operators showed that they earn similar levels of education compared to general machine operators. So much so that theyacirc;euro;trade;re 0.4% less likely to earn a Master's Degree and less likely to earn a Doctoral Degree by 0.0%.Types of general machine operator

Updated January 8, 2025