What does a high lift operator do?

High lift operator responsibilities

Here are examples of responsibilities from real high lift operator resumes:

- Inventory control and making sure wrapped fill pallets are accurately account and labele before exiting the building.

- Maintain proper housekeeping and guidelines set forth by OSHA and management.

- Operate fork-lift to transport finish product to shipping warehouse for distribution.

- Maintain safe and clean work environment by keeping shelves, pallet area, and workstations.

- Experience with setting up LTL, FTL, and FedEx/UPS shipments via phone or computer.

High lift operator skills and personality traits

We calculated that 26% of High Lift Operators are proficient in Pallets, OSHA, and Load Trucks. They’re also known for soft skills such as Alertness, Communication skills, and Coordination.

We break down the percentage of High Lift Operators that have these skills listed on their resume here:

- Pallets, 26%

Pick items for the stores and make pallets for them to be sent to Giant Eagle stores

- OSHA, 16%

Maintained accurate and timely documentation as is required by organization and OSHA.

- Load Trucks, 15%

Unload trucks and receive product using RF scan gun to close PO's noting damages and deficiencies.

- Pallet Jack, 15%

Tow Motor operator Power pallet jack operator

- Safety Standards, 6%

Enforced safety standards by preparing composite risk management assessments for individual training exercises and various operations throughout South Korea.

- Store Merchandise, 4%

Operated forklift to retrieve and store merchandise.

Common skills that a high lift operator uses to do their job include "pallets," "osha," and "load trucks." You can find details on the most important high lift operator responsibilities below.

Communication skills. Another essential skill to perform high lift operator duties is communication skills. High lift operators responsibilities require that "material moving machine operators signal and direct workers to load and unload material." High lift operators also use communication skills in their role according to a real resume snippet: "maintained necessary level of communications between shifts ensured that all health and safety guidelines were followed. "

Coordination. Another skill that relates to the job responsibilities of high lift operators is coordination. This skill is critical to many everyday high lift operator duties, as "material moving machine operators must have steady hands and feet to guide and control heavy machinery precisely." This example from a resume shows how this skill is used: "maintained good communication with supervisors, managers, and co-workers for proper safety procedures and coordination of various shipments. "

Mechanical skills. For certain high lift operator responsibilities to be completed, the job requires competence in "mechanical skills." The day-to-day duties of a high lift operator rely on this skill, as "material moving machine operators make minor adjustments to their machines and perform basic maintenance on them." For example, this snippet was taken directly from a resume about how this skill applies to what high lift operators do: "operate forklift loading and unloading trucks and kilns* feed dried lumber to grading crew* light mechanical and preventive maintenance. "

Visual ability. A commonly-found skill in high lift operator job descriptions, "visual ability" is essential to what high lift operators do. High lift operator responsibilities rely on this skill because "material moving machine operators must be able to see clearly where they are driving or what they are moving." You can also see how high lift operator duties rely on visual ability in this resume example: "maintained a moderate level of visual attention and mental concentration for extended periods of time while properly stacking products on pallets. "

The three companies that hire the most high lift operators are:

- Four Seasons Produce29 high lift operators jobs

- ABM Industries3 high lift operators jobs

- Dollar Tree1 high lift operators jobs

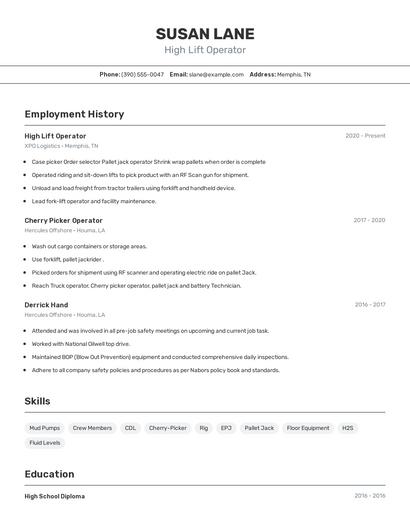

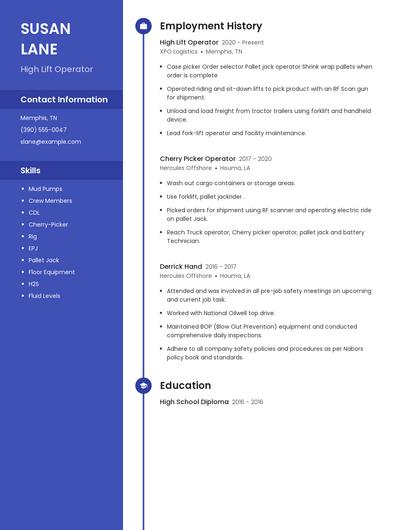

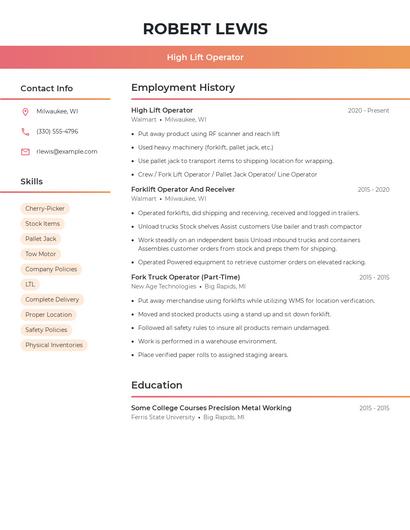

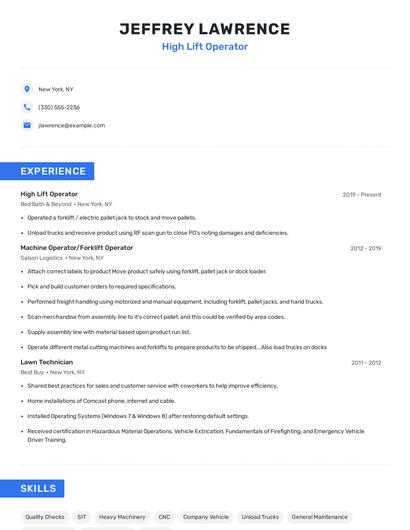

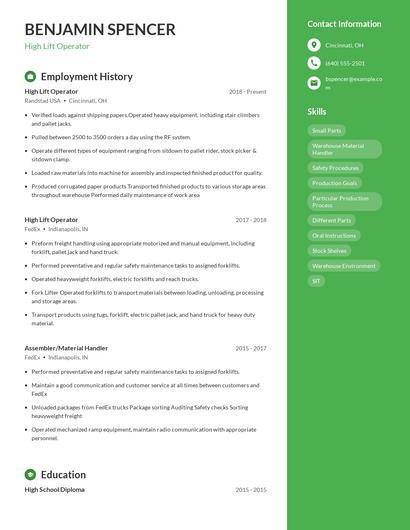

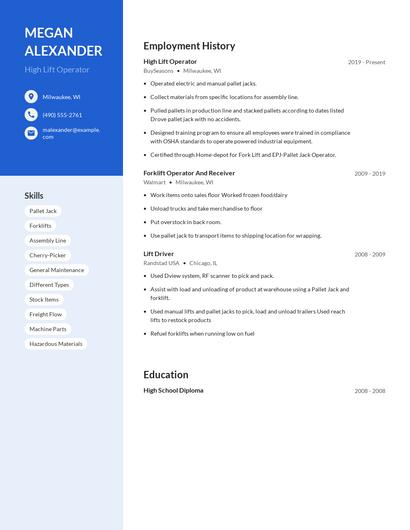

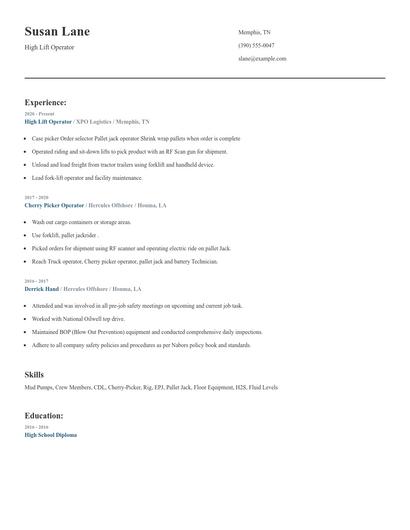

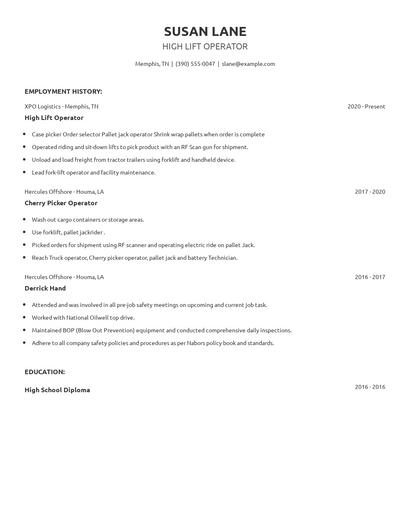

Choose from 10+ customizable high lift operator resume templates

Build a professional high lift operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your high lift operator resume.Compare different high lift operators

High lift operator vs. Warehouse machine operator

Warehouse machine operators perform various tasks for their employers. These include setting up, operating, monitoring, and troubleshooting machinery, inspecting parts for specifications and any potential damage, and reading and interpreting diagrams and blueprints to position and secure the machines. They are expected to communicate with other team members and provide support for continuous production. Most employers are looking to hire someone with knowledge of production and safety procedures, previous experience as a machine operator, and analytical skills.

These skill sets are where the common ground ends though. The responsibilities of a high lift operator are more likely to require skills like "pallets," "osha," "pallet jack," and "outbound orders." On the other hand, a job as a warehouse machine operator requires skills like "basic math," "safety regulations," "electric pallet jack," and "shipping receiving." As you can see, what employees do in each career varies considerably.

Warehouse machine operators tend to make the most money working in the manufacturing industry, where they earn an average salary of $36,642. In contrast, high lift operators make the biggest average salary, $39,420, in the construction industry.The education levels that warehouse machine operators earn slightly differ from high lift operators. In particular, warehouse machine operators are 0.4% more likely to graduate with a Master's Degree than a high lift operator. Additionally, they're 0.1% more likely to earn a Doctoral Degree.High lift operator vs. Mechanical spreader operator

A mechanical spreader operators manage and operate all equipment in various industries where they perform their jobs. The operators work as general mechanics in building HVAC, general building maintenance, and pump station operations. They test electro-mechanical subsystems for operational reliability and circuit integrity. Their job includes promoting quality assurance and performance improvement programs within the organization. Also, they perform an energy audit to improve the efficiency of HVAC energy.

In addition to the difference in salary, there are some other key differences worth noting. For example, high lift operator responsibilities are more likely to require skills like "pallets," "osha," "load trucks," and "pallet jack." Meanwhile, a mechanical spreader operator has duties that require skills in areas such as "hand tools," "plumbing," "preventive maintenance," and "safety procedures." These differences highlight just how different the day-to-day in each role looks.

Mechanical spreader operators earn a higher average salary than high lift operators. But mechanical spreader operators earn the highest pay in the energy industry, with an average salary of $48,520. Additionally, high lift operators earn the highest salaries in the construction with average pay of $39,420 annually.In general, mechanical spreader operators achieve similar levels of education than high lift operators. They're 2.0% more likely to obtain a Master's Degree while being 0.1% more likely to earn a Doctoral Degree.High lift operator vs. Lift driver

A lift driver is responsible for operating warehouse machines and vehicles, especially on loading and unloading items from distribution trucks and transporting the merchandise to different parts of the warehouse. Lift drivers inspect the efficiency and reliability of the machines, ensuring its operational and optimal performance to avoid production delays. They also verify the number of products for distribution according to the order requests and shipment details. A lift driver must be highly-organized, as well as having excellent time-management skills to perform duties and meet strict production schedules.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a high lift operator is likely to be skilled in "osha," "pallet jack," "outbound orders," and "store merchandise," while a typical lift driver is skilled in "fork-lift," "electric pallet jack," "hand trucks," and "safety rules."

Lift drivers earn the best pay in the automotive industry, where they command an average salary of $38,145. High lift operators earn the highest pay from the construction industry, with an average salary of $39,420.When it comes to education, lift drivers tend to earn similar degree levels compared to high lift operators. In fact, they're 0.7% more likely to earn a Master's Degree, and 0.1% more likely to graduate with a Doctoral Degree.High lift operator vs. Cherry picker operator

Cherry pickers perform a safe and efficient operation of motorized lift vehicles in pulling customer order-based products. The cherry pickers manage different warehouse operating systems and associates to support processing and internal order logistics. They perform preventive maintenance on pallet packs, machines, cherry pickers, and forklifts. It is part of their job to count, verify, and check documents for completeness and accuracy. The skills to develop for this job include warehouse environment, clamp, and pallet jack operations.

Types of high lift operator

Updated January 8, 2025