Automatically apply for jobs with Zippia

Upload your resume to get started.

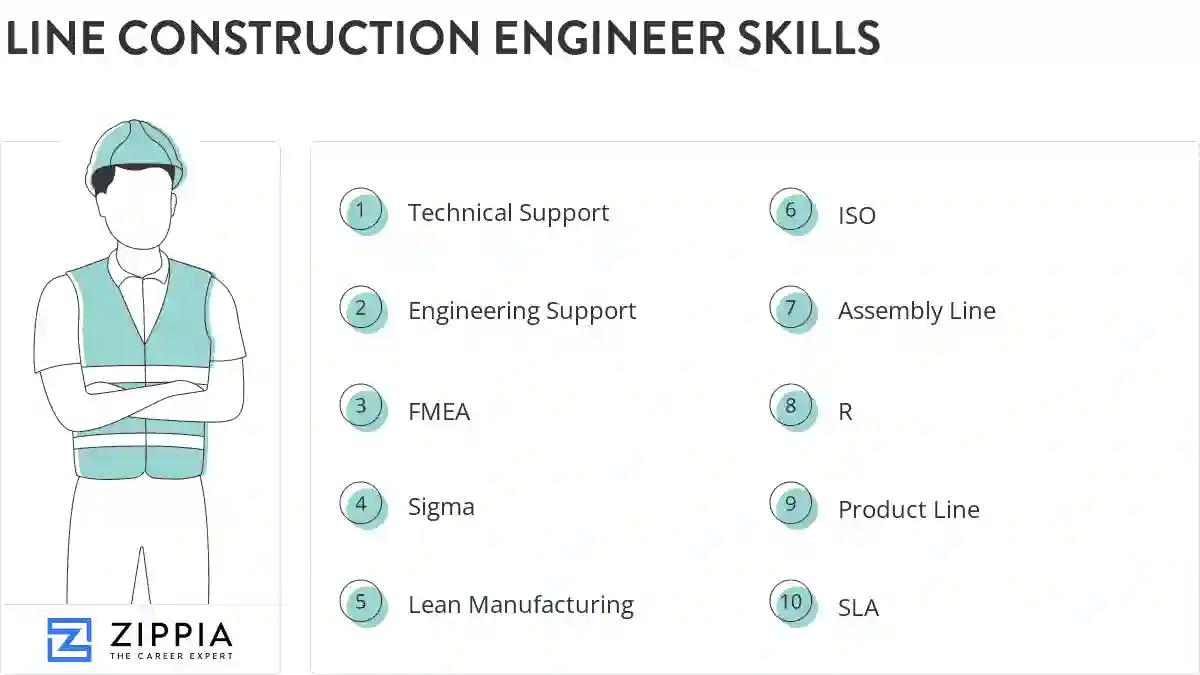

Line construction engineer skills for your resume and career

14 line construction engineer skills for your resume and career

1. Technical Support

Technical support or tech support are the services provided by any hardware or software company to users. They help in solving the technical difficulties the customers face with their products or services. Moreover, the tech support employees maintain, manage, and repair the IT faults. They are also responsible for resolving the network problems, installing and configuring hardware and software.

- Prioritized severity of service disruptions and dispatched onsite technical support.

- Helped increase equipment availability factor by responding to emergent issues and providing technical support to safely meet outages schedules.

2. Engineering Support

Engineering support means providing assistance to different engineers working in the company. It enables them to complete their tasks effectively and timely. Engineering support revolves around diagnosing and resolving software and hardware problems. They also look for network issues and resolve them in a timely manner.

- Provided engineering support to the 456 blanker and choppers for the start departments.

- Provide engineering support to the Regional Offices throughout Allegheny Power's Territory.

3. FMEA

- Generated FMEA (Failure Mode & Effect Analysis) and process evaluation and recommendations for supporting manufacturing failure investigation activities.

- Implemented first PdM technologies project by applying FMEA methodology to identify opportunities for detection and avoidance of future equipment failures.

4. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Contributed to the Caterpillar Quality Management System Certification by performing internal audit and coordinating a Six Sigma Black Belt project.

- Participated in multiple Lean Manufacturing/Six Sigma process improvement initiatives to include comparing and obtaining new equipment for hydro forming parts.

5. Lean Manufacturing

- Increased profitability through Lean manufacturing concepts by a minimum of 3% per year.

- Established "Lean Manufacturing" processes as part of Continuous Operational and Process Excellence.

6. ISO

- Implemented automated methods for the reporting of ISO 9002 quality issues and reporting/tracking customer complaints and follow-up actions for Operations.

- Performed manufacturing engineering functions for final assembly operations; led productivity and quality improvement projects including ISO 9001:2000 Certification and Maintenance.

Choose from 10+ customizable line construction engineer resume templates

Build a professional line construction engineer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your line construction engineer resume.7. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Created visual work instructions for new 2011 model year Case backhoe cab assembly line.

- Managed successful relocation of 50,000 sq ft assembly line to adjacent area.

8. R

R is a free software environment and a language used by programmers for statistical computing. The R programming language is famously used for data analysis by data scientists.

- Applied statistical methods to manufacturing disciplines including X-bar and R charts, process capability studies and problem identification/solving activities.

- Developed and used X-bar R charts to determine process variation for dry film thickness of paint process.

9. Product Line

Product line is a collection of similar or related products that may be under a single brand manufactured by the same company. It may include different varieties of a specific product of a brand which comes in different categories. In other cases, the product line may differ in some characteristics despite being from the same manufacturer.

- Designed new area layouts for product line acquisition and collaborated with process owners for plant redesign for company-wide plant standardization initiative.

- Designed process flows, trained manufacturing/quality teams and executed process validations to launch newly integrated product lines into new manufacturing site.

10. SLA

SLA refers to Service-level Agreement. It is an agreement between a customer and the service provider on the quality of service and what standards they must meet.

- Top performer for the Dell Pro Support Project maintaining SLA

- Contract to hire for Convergys 4 months Top performer for the Dell Pro Support Project maintaining SLA

11. KPI

- Follow up the SIM board and reporting KPI's.

12. Routine Maintenance

- Clean and check tools and equipment, perform routine maintenance in preparation for next job.

- Perform routine maintenance at customer location to achieve an uptime rate of 98 percent.

13. Windows

Windows is a chain of operating systems that controls a computer and is developed by Microsoft. Every version of Windows consists of GUI (graphical user interface), with a desktop that allows the user to open their files.

- Received several HP certifications in Windows troubleshooting on HP PCs, PC Security, and Customer Satisfaction.

- Traveled to HP's campus in Houston, TX to have Windows 7 training.

14. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Determined manufacturing requirements and quality assurance measures through to use of operational process planning drawings and inspection reports for CNC machined components

- Developed CNC programs and setup drawings utilizing Pro/Engineering and Pro/Manufacturing software for machining centers, lathes and flexible manufacturing cells.

What skills help Line Construction Engineers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of line construction engineer skills to add to your resume

The most important skills for a line construction engineer resume and required skills for a line construction engineer to have include:

- Technical Support

- Engineering Support

- FMEA

- Sigma

- Lean Manufacturing

- ISO

- Assembly Line

- R

- Product Line

- SLA

- KPI

- Routine Maintenance

- Windows

- CNC

Updated January 8, 2025