What does a line supervisor do?

A line supervisor is responsible for monitoring the line operations within an organization, ensuring the adequacy of line staff on production, and supervising the quality control processes. Line supervisors enforce the highest safety standards and procedures within the premises to avoid operation hazards that might cause delays in the production. They also train new employees, coordinate with the management for process improvement, and develop strategic techniques to minimize excessive costings without compromising the service quality.

Line supervisor responsibilities

Here are examples of responsibilities from real line supervisor resumes:

- Manage the quality control, safety, and sanitation for the second-process of poultry processing while adhering to FDA regulations.

- Manage and develop associates base on organizational and developmental needs/conduct monthly one-on-ones with each employee to provide guidance and leadership.

- Schedule crewing (union shop), production scheduling, MRP.

- Run mechanical machinery to package FDA control medicine, build cardboard displays for different products and package them.

- Operate manual and pneumatic tools and machinery used in the maintenance of vessels, HVAC and ice arena equipment.

- Train maintenance personnel in diagnosing and repairing machines to minimize downtime and cost associated with the operation of all machinery.

- Delegate responsibilities to decrease downtime and improve efficiency within the department.

- Manage and develop associates base on organizational and developmental needs/conduct monthly one-on-ones with each employee to provide guidance and leadership.

- Cut sheet metal using either a CNC or hand shear for use in a brake press to form trim.

- Set up a cellular manufacturing cell with 12 CNC turning centers that reduce headcount and 2500 square feet of floor space.

- Coordinate workload to a team of finishers.

- Maintain all supplies for finishers so production can keep running.

- Work with negotiating team and the UAW, IAM, and USW to successfully implement work teams with hourly group leaders.

- Verify quantity and quality of stock receive by manufacturer and report irregularities to QC.

- Improve existing procedures and enhance QC processes while establishing an open communication between engineering, welders, and management.

Line supervisor skills and personality traits

We calculated that 15% of Line Supervisors are proficient in Safety Procedures, Direct Supervision, and Safety Rules.

We break down the percentage of Line Supervisors that have these skills listed on their resume here:

- Safety Procedures, 15%

Evaluated maintenance operations and facilities daily for compliance with directives, technical manuals, standard operating procedures, and safety procedures.

- Direct Supervision, 14%

Direct supervision of 12 union hourly packaging operators.

- Safety Rules, 8%

Follow all departmental safety rules and regulations and put on all appropriate safety gear and clothing/protection required by assigned work activities.

- Continuous Improvement, 6%

Managed production scheduling, manning requirements, safety and quality standards, training, inventory and continuous improvements.

- Food Safety, 5%

Trained workers according to food safety regulations.

- Assembly Line, 5%

Introduced many improvements upon assembly line to increase stability and efficiency.

Most line supervisors use their skills in "safety procedures," "direct supervision," and "safety rules" to do their jobs. You can find more detail on essential line supervisor responsibilities here:

The three companies that hire the most line supervisors are:

- AVANGRID58 line supervisors jobs

- YRC Freight20 line supervisors jobs

- Yellow11 line supervisors jobs

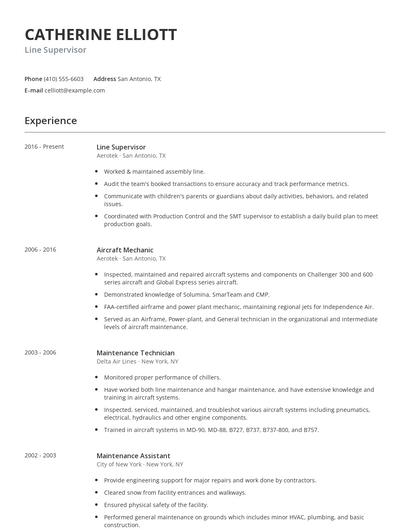

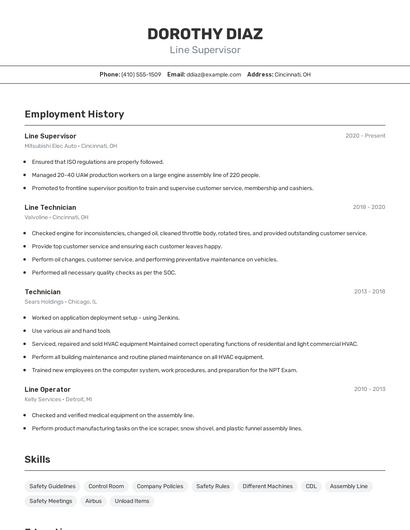

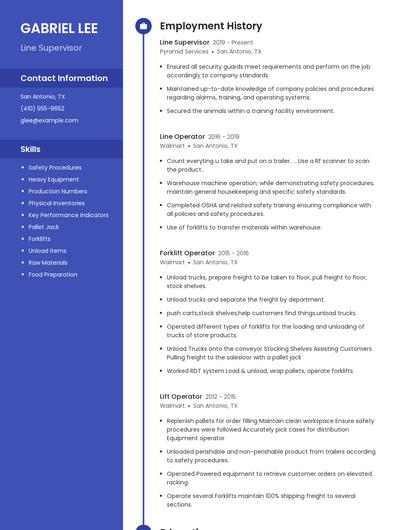

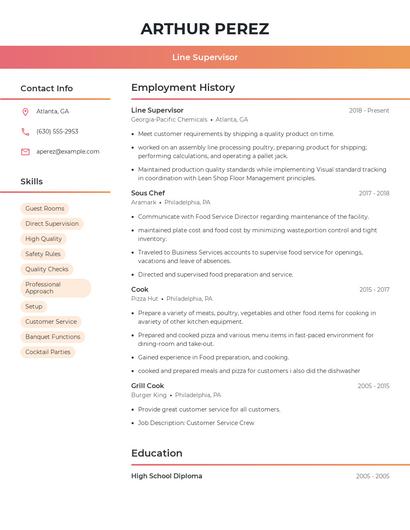

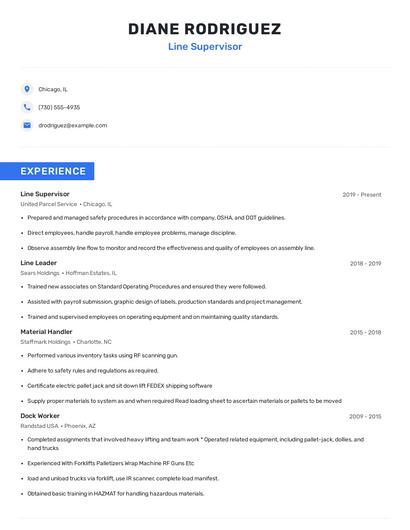

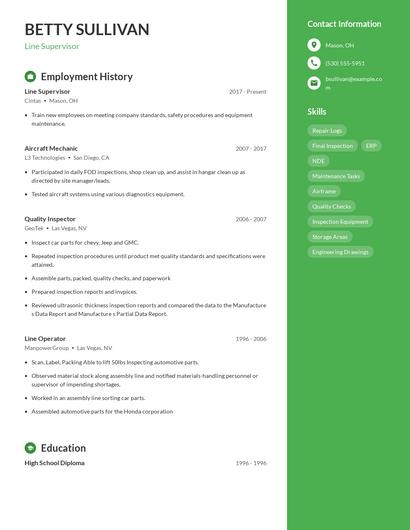

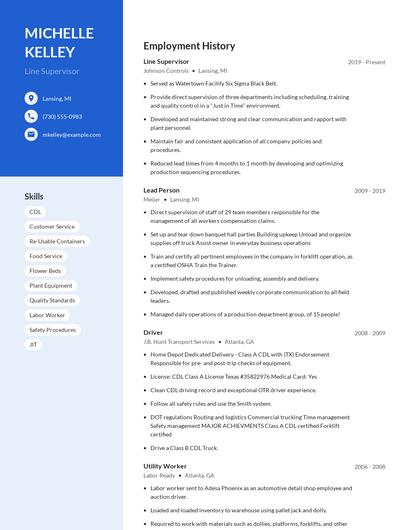

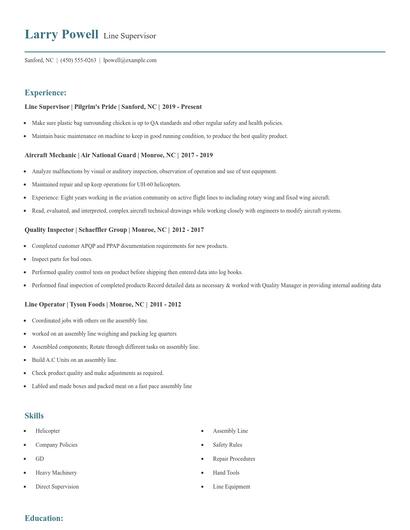

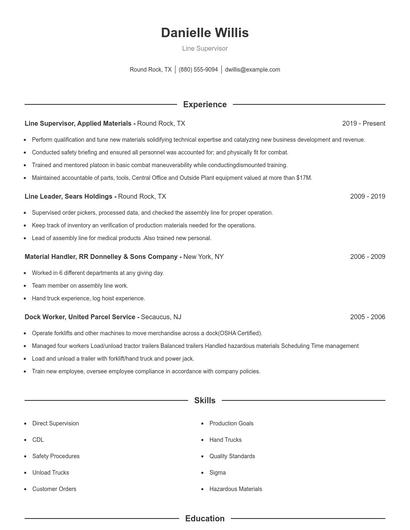

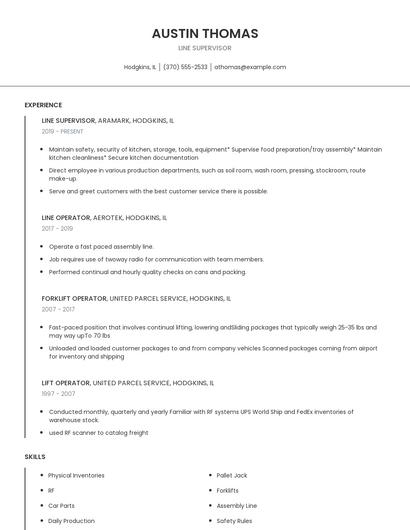

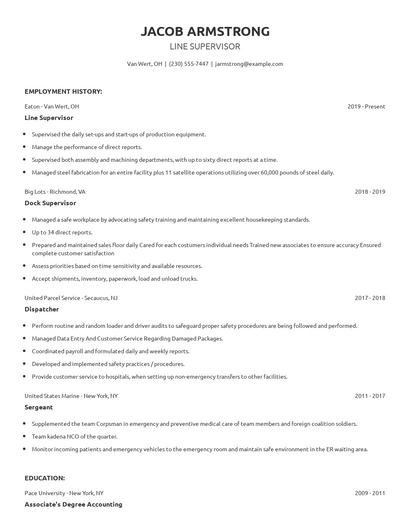

Choose from 10+ customizable line supervisor resume templates

Build a professional line supervisor resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your line supervisor resume.Compare different line supervisors

Line supervisor vs. Production supervisor/manager

Production supervision managers display strong skills in supervision, decision-making, effective planning, and also have a keen eye for detail. This career will call on the maintenance of a production line's operations, as well as the ongoing production of the end product, in addition to maximizing production while maintaining quality products and staff safety.

While similarities exist, there are also some differences between line supervisors and production supervisor/manager. For instance, line supervisor responsibilities require skills such as "direct supervision," "food safety," "assembly line," and "collective bargaining." Whereas a production supervisor/manager is skilled in "spc," "production supervisors," "lean manufacturing," and "on-time delivery." This is part of what separates the two careers.

The education levels that production supervisors/manager earn slightly differ from line supervisors. In particular, production supervisors/manager are 2.7% more likely to graduate with a Master's Degree than a line supervisor. Additionally, they're 0.2% more likely to earn a Doctoral Degree.Line supervisor vs. Shift production supervisor

A shift production supervisor is in charge of overseeing business operations, ensuring efficiency and smooth workflow. Their responsibilities revolve around devising strategies to reach production standards and production targets, supervising and assessing staff performance, delegating tasks, managing schedules, and prioritizing customer satisfaction. They may also produce progress reports and presentations, address and resolve any issues or concerns, and train new workforce members. Furthermore, as a supervisor, it is essential to lead and encourage team members, all while implementing the company's policies and regulations.

Each career also uses different skills, according to real line supervisor resumes. While line supervisor responsibilities can utilize skills like "direct supervision," "safety rules," "food safety," and "assembly line," shift production supervisors use skills like "lean manufacturing," "osha," "lean six sigma," and "sigma."

Average education levels between the two professions vary. Shift production supervisors tend to reach similar levels of education than line supervisors. In fact, they're 0.3% more likely to graduate with a Master's Degree and 0.2% less likely to earn a Doctoral Degree.Line supervisor vs. Night shift supervisor

A Night Shift Supervisor is a person who manages and supervises night shift production. Their responsibilities include: providing good customer services, ensuring efficiencies of tasks, ensuring cost objectives are met, training and guiding a team of workers, ensuring staff and the working environment is in line with compliance standards, help the site team ensure the company specifications on products are made with the quality of the products intact, acting as a communication bridge between associates and management to address key issues and conducting minor repairs during their shift to ensure the work does not lag.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from line supervisor resumes include skills like "direct supervision," "continuous improvement," "food safety," and "assembly line," whereas a night shift supervisor is more likely to list skills in "patients," "customer service," "cpr," and "preventative maintenance. "

When it comes to education, night shift supervisors tend to earn similar degree levels compared to line supervisors. In fact, they're 0.4% less likely to earn a Master's Degree, and 0.0% less likely to graduate with a Doctoral Degree.Line supervisor vs. Quality assurance supervisor

A quality assurance supervisor oversees and leads the quality control operations within a manufacturing plant or similar establishment. They are primarily responsible for crafting and implementing policies that prioritize the efficiency of products or services, supervising and evaluating the performances of the workforce, and setting standards and procedures that align not just with the goals of the company, but the national and international level of production standards. Furthermore, as a supervisor in the field, it is crucial to encourage and shape quality assurance workers into valuable members of the company.

Types of line supervisor

Updated January 8, 2025