What does a machine set up operator do?

Machine set up operator responsibilities

Here are examples of responsibilities from real machine set up operator resumes:

- Perform trial runs on new CNC programs, working with programming and tooling to achieve satisfactory parts.

- Used micrometers and calipers to determine require tolerances.

- Follow ISO and QS standard operating procedures.

- Panel control, fanuc control, & dynapath.

- Run machines after setup, inspect parts run.

- Work on CNC OKUMA machines, horizontals and verticals.

- Operate hass machine and okuma mill to make the wheel

- Used scribes, gauges, and digital comparators for quality control.

- Work with ISO coordinator to ensure quality control on 2nd shift.

- Set up and run Okumas and Mazaks for high production jobs.

- Used shop math to read metric or standard base off of prints.

- Apply math skills, extensive multitasking, and problem solving while setting up machines.

- Set up and operation of Haas horizontal lathes and Haas vertical lates to include.

- weld setupsetup resistance welders, cnc and plc equipment, wire benders and presses.

- Operate CMM for EDM machines using precision tools to scooter gauges, micrometers, and verniers.

Machine set up operator skills and personality traits

We calculated that 13% of Machine Set Up Operators are proficient in CNC Machines, Calipers, and Micrometers. They’re also known for soft skills such as Computer skills, Dexterity, and Physical strength.

We break down the percentage of Machine Set Up Operators that have these skills listed on their resume here:

- CNC Machines, 13%

Set up various CNC machines, troubleshooting and operation of machines, making parts in the manufacturing of furniture.

- Calipers, 10%

Handled measuring tools (Calipers, Micrometers, etc) and read them in English and Metric units.

- Micrometers, 9%

Operated CMM for EDM machines using precision tools to scooter gauges, micrometers, and verniers.

- CNC Lathes, 6%

Set up and programmed a variety of CNC lathes, drills, and mills for mass production parts.

- Quality Checks, 5%

Performed quality checks of manufacturing processes and finish products to assure compliance with company requirements and customer s expectations.

- Math, 5%

Produced and maintained accurate documentation for production reports using math and computer skills.

"cnc machines," "calipers," and "micrometers" are among the most common skills that machine set up operators use at work. You can find even more machine set up operator responsibilities below, including:

Computer skills. The most essential soft skill for a machine set up operator to carry out their responsibilities is computer skills. This skill is important for the role because "metal and plastic machine workers often must be able to use programmable devices, computers, and robots on the factory floor." Additionally, a machine set up operator resume shows how their duties depend on computer skills: "use a computer to enter production and printing cards, to use, understand and properly respond to spc results. "

Dexterity. Another soft skill that's essential for fulfilling machine set up operator duties is dexterity. The role rewards competence in this skill because "metal and plastic machine workers who work in metal and plastic machined goods manufacturing use precise hand movements to make the necessary shapes, cuts, and edges that designs require." According to a machine set up operator resume, here's how machine set up operators can utilize dexterity in their job responsibilities: "operated a sit down forklift to set -up a punch press machine. "

Physical strength. Another skill that relates to the job responsibilities of machine set up operators is physical strength. This skill is critical to many everyday machine set up operator duties, as "metal and plastic machine workers must be strong enough to guide and load heavy and bulky parts and materials into machines." This example from a resume shows how this skill is used: "inspect product for quality using physical and spc methods. "

Mechanical skills. A big part of what machine set up operators do relies on "mechanical skills." You can see how essential it is to machine set up operator responsibilities because "metal and plastic machine workers set up and operate machinery." Here's an example of how this skill is used from a resume that represents typical machine set up operator tasks: "operated brake press, setup mechanical punch press. "

The three companies that hire the most machine set up operators are:

- Award Staffing

9 machine set up operators jobs

- SMS group7 machine set up operators jobs

- U.S. Tsubaki Power Transmission6 machine set up operators jobs

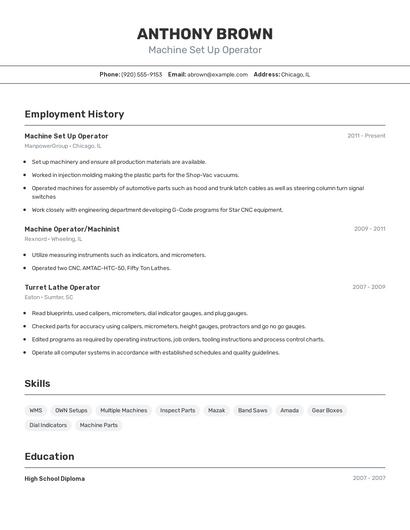

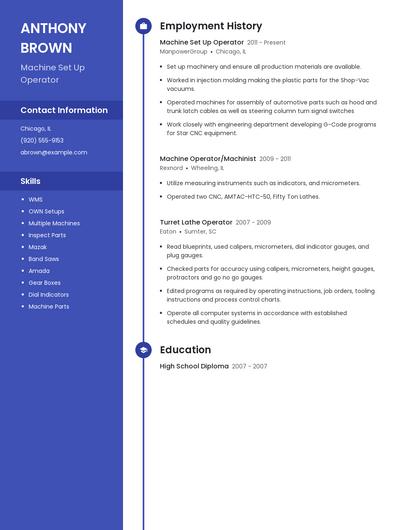

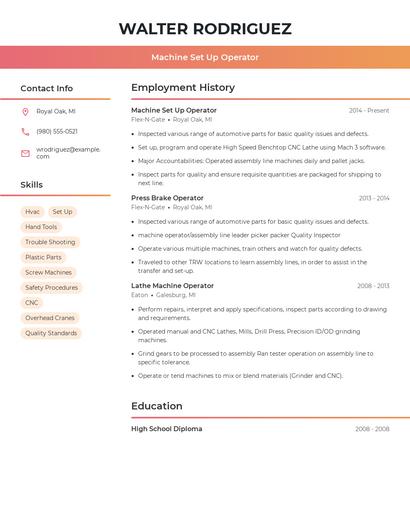

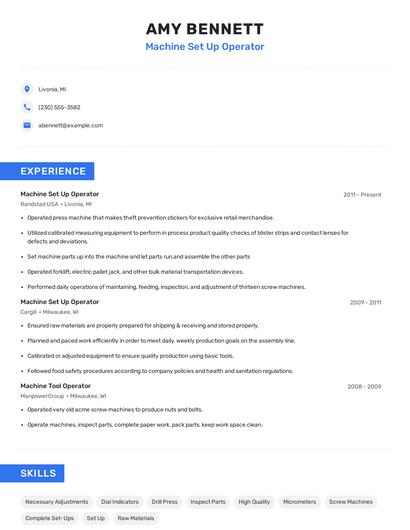

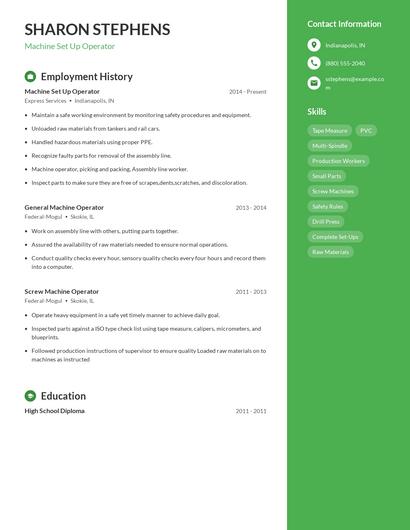

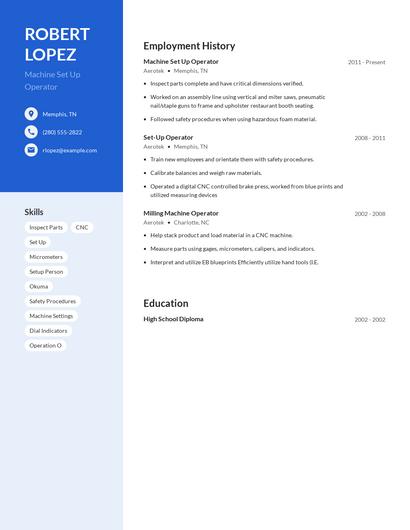

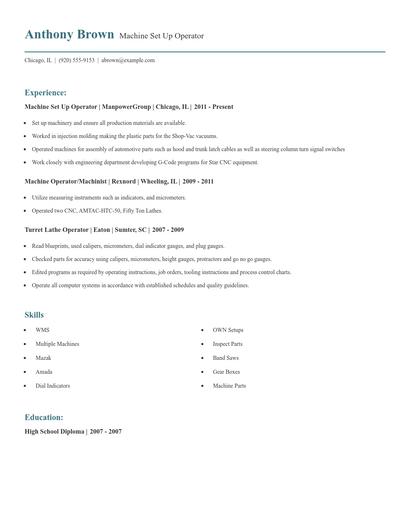

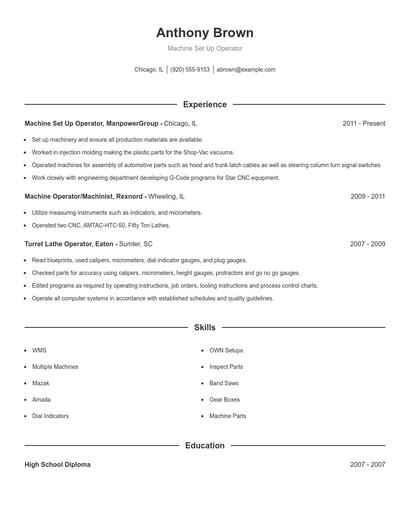

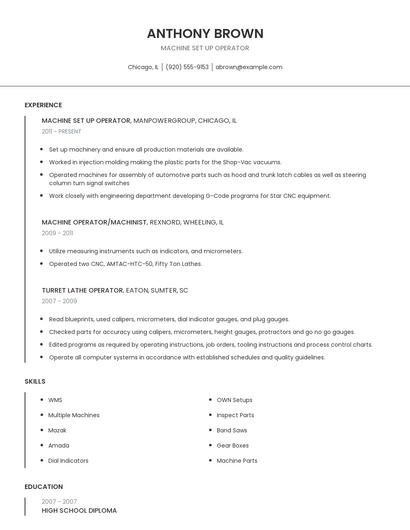

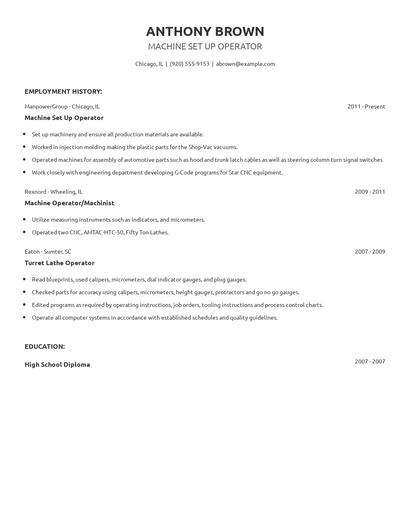

Choose from 10+ customizable machine set up operator resume templates

Build a professional machine set up operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your machine set up operator resume.Compare different machine set up operators

Machine set up operator vs. Machinist

Machinists are skilled professionals who create metal works by using different machines. They work with clients to bring their clients' vision to life. They study the blueprints of the product that needs to be done and identify the parts that will need fabrication through machining. They then prepare the materials and equipment. Machinists use different tools such as grinders, drills, lathes, polishers, and milling equipment to create parts that are made of metal. They may sometimes work with other materials such as wood or plastic, but this is seldom. Machinists are expected to be proficient in the use of the machines, to be precise with their work, and can work within the committed timeline.

These skill sets are where the common ground ends though. The responsibilities of a machine set up operator are more likely to require skills like "dexterity," "basic math," "quality products," and "quality standards." On the other hand, a job as a machinist requires skills like "grinders," "machine shop," "hand tools," and "shop equipment." As you can see, what employees do in each career varies considerably.

Machinists earn the highest salaries when working in the automotive industry, with an average yearly salary of $53,086. On the other hand, machine set up operators are paid more in the automotive industry with an average salary of $39,440.On average, machinists reach similar levels of education than machine set up operators. Machinists are 0.3% more likely to earn a Master's Degree and 0.0% less likely to graduate with a Doctoral Degree.Machine set up operator vs. Set up technician

Set up technicians are skilled employees who assemble and disassemble manufacturing machines as well as perform preventative maintenance to ensure that the manufacturing firm can produce high-quality products. These technicians must inspect products so that they can locate malfunctions in machine operations and then inform their supervisor about the repairs needed. They must observe production equipment to ensure its correct operation and collaborate with the engineering team to adjust the equipment when needed. Set up technicians must also assist in teaching new operators about the firm's standard operating procedures of production equipment.

In addition to the difference in salary, there are some other key differences worth noting. For example, machine set up operator responsibilities are more likely to require skills like "cnc machines," "micrometers," "cnc lathes," and "dexterity." Meanwhile, a set up technician has duties that require skills in areas such as "hand tools," "cnc," "safety procedures," and "good communication." These differences highlight just how different the day-to-day in each role looks.

Set up technicians may earn a higher salary than machine set up operators, but set up technicians earn the most pay in the professional industry with an average salary of $38,989. On the other hand, machine set up operators receive higher pay in the automotive industry, where they earn an average salary of $39,440.set up technicians earn similar levels of education than machine set up operators in general. They're 0.1% less likely to graduate with a Master's Degree and 0.0% more likely to earn a Doctoral Degree.Machine set up operator vs. Numerical control operator

A numerical control operator is responsible for monitoring machinery and managing computer-generated equipment to produce tools and components from various mechanical resources. Numerical control operators must have extensive knowledge with the technology and mechanical industry to perform basic troubleshooting and detect malfunctions during operations. A numerical control operator duties' also include inspecting equipment setup and finished products, ensuring high-quality parts, reviewing blueprints, following client's specifications for making adjustments, and adhering to the safety guidelines and procedures required by the business.

The required skills of the two careers differ considerably. For example, machine set up operators are more likely to have skills like "cnc machines," "cnc lathes," "dexterity," and "quality products." But a numerical control operator is more likely to have skills like "lathe machines," "hand tools," "safety standards," and "troubleshoot."

Numerical control operators make a very good living in the automotive industry with an average annual salary of $41,888. On the other hand, machine set up operators are paid the highest salary in the automotive industry, with average annual pay of $39,440.Most numerical control operators achieve a similar degree level compared to machine set up operators. For example, they're 0.1% more likely to graduate with a Master's Degree, and 0.0% more likely to earn a Doctoral Degree.Machine set up operator vs. Press brake operator

A press brake is a machine used to manipulate metal into various shapes and forms. Press brake operators manufacture tools, metal, and other pieces of equipment using a press brake to make punches, bends, and cuts into sheet or plate metal. These operators may have their own business, work in a factory setting, or other types of machinery shops.

Even though a few skill sets overlap between machine set up operators and press brake operators, there are some differences that are important to note. For one, a machine set up operator might have more use for skills like "cnc machines," "micrometers," "cnc lathes," and "dexterity." Meanwhile, some responsibilities of press brake operators require skills like "hand tools," "safety procedures," "hydraulic press," and "cnc brake. "

Press brake operators enjoy the best pay in the finance industry, with an average salary of $40,158. For comparison, machine set up operators earn the highest salary in the automotive industry.In general, press brake operators hold similar degree levels compared to machine set up operators. Press brake operators are 0.5% less likely to earn their Master's Degree and 0.1% less likely to graduate with a Doctoral Degree.Types of machine set up operator

Updated January 8, 2025