What does a maintenance operator do?

Maintenance operators are skilled technicians who use a variety of small equipment and tools to perform and assist in the maintenance activities of a business establishment. These operators are required to assist the equipment manager in preparing preventative maintenance procedures so that they can increase productivity and reduce downtime of equipment. They must enforce safety rules and regulations and ensure that staff members are following them to prevent accidents in the facility. Maintenance operators must also train maintenance employees in performing proper preventative maintenance.

Maintenance operator responsibilities

Here are examples of responsibilities from real maintenance operator resumes:

- Perform daily checks of pumps, gas blowers, conveyor systems, and gas quality.

- Ensure a neat and orderly work area following OSHA standards to promote a safe work environment.

- Maintain hydraulic systems, pneumatic systems, electrical systems, gas equipment, HVAC and AC/DC systems.

- Maintain proper storage area for all equipment and chemicals used for park maintenance according to appropriate OSHA standards.

- Repair PVC plumbing, motors, electric actuators, pH probes, ultrasonic level controls, and chemical injection systems.

- Refurbish office equipment and plumbing fixtures.

- Compile energy usage and environmental statistics for electrical and HVAC departments.

- Maintain equipment cleanliness during all process operations so as not to jeopardize product quality and/or purity.

- Maintain and develop positive business relationships with a customer's key personnel involve in or directly relevant to a logistics activity.

Maintenance operator skills and personality traits

We calculated that 8% of Maintenance Operators are proficient in Hand Tools, CDL, and Preventative Maintenance. They’re also known for soft skills such as Customer-service skills, Dexterity, and Troubleshooting skills.

We break down the percentage of Maintenance Operators that have these skills listed on their resume here:

- Hand Tools, 8%

Maintain hand tools with safe and clean working environment by complying with procedures, rules and regulations.

- CDL, 8%

Have CDL would drive swab unit to job and rig up and swab well in then turn it over to production

- Preventative Maintenance, 7%

Established a computerized maintenance management program performing preventative maintenance on all equipment used to operate municipal water plants and distribution systems.

- Mowing, 5%

Maintained building and grounds; lawn mowing, cleaning, painting, etc.

- Safety Procedures, 4%

Trained in Quality control and followed extensive safety procedures.

- Dump Truck, 4%

Operated and serviced heavy machinery such as: bulldozers, front-end loaders, track hoes, and off-road dump trucks.

"hand tools," "cdl," and "preventative maintenance" are among the most common skills that maintenance operators use at work. You can find even more maintenance operator responsibilities below, including:

Customer-service skills. To carry out their duties, the most important skill for a maintenance operator to have is customer-service skills. Their role and responsibilities require that "these workers interact with customers on a regular basis." Maintenance operators often use customer-service skills in their day-to-day job, as shown by this real resume: "assist with customer and administrative duties related to building maintenance. "

Dexterity. Another essential skill to perform maintenance operator duties is dexterity. Maintenance operators responsibilities require that "many repair and maintenance tasks, such as repairing small devices, connecting or attaching components, and using hand tools, require a steady hand and good hand–eye coordination." Maintenance operators also use dexterity in their role according to a real resume snippet: "saw operator, assembler, material handling, torching various forklifts, shipping and receiving building maintenance safety committee"

Troubleshooting skills. maintenance operators are also known for troubleshooting skills, which are critical to their duties. You can see how this skill relates to maintenance operator responsibilities, because "workers find, diagnose, and repair problems." A maintenance operator resume example shows how troubleshooting skills is used in the workplace: "worked with nurse call systems, electrical troubleshooting, and various other patient related concerns. "

The three companies that hire the most maintenance operators are:

- McDonald's74 maintenance operators jobs

- Vail Resorts13 maintenance operators jobs

- Hubbell10 maintenance operators jobs

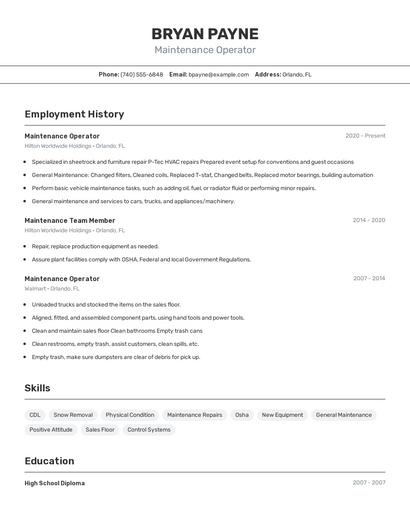

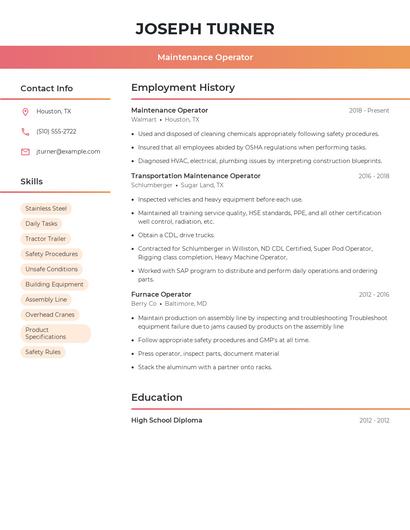

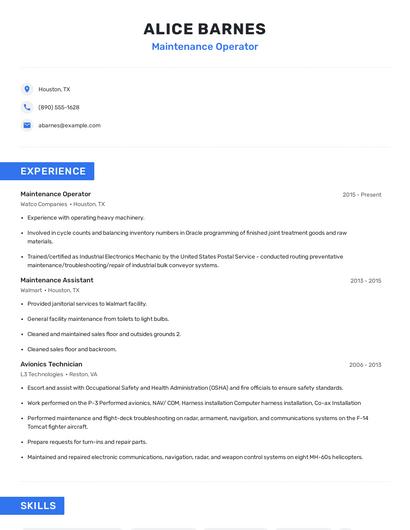

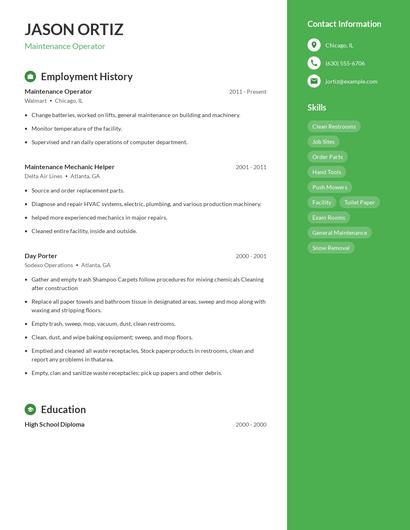

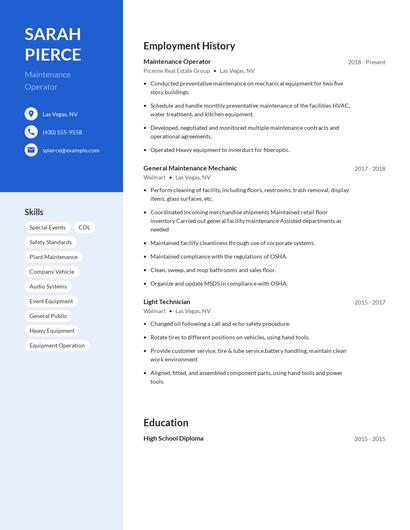

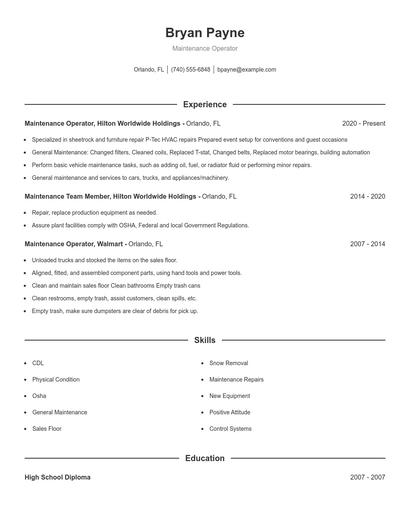

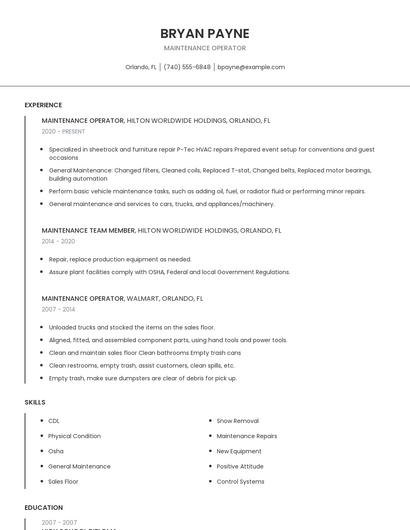

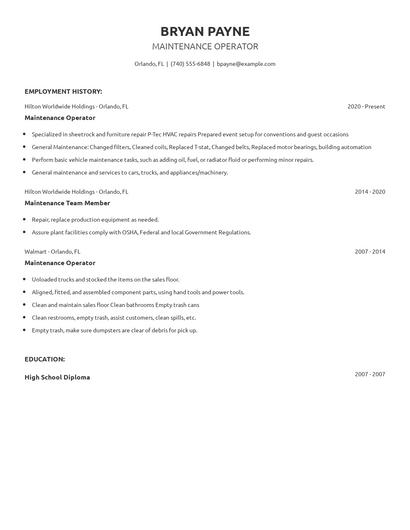

Choose from 10+ customizable maintenance operator resume templates

Build a professional maintenance operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your maintenance operator resume.Compare different maintenance operators

Maintenance operator vs. Operations and maintenance technician

Operations and maintenance technicians are skilled professionals who are responsible for conducting preventive maintenance of all equipment used in the operation of an organization. These technicians are required to ensure that their facilities are always operational by performing inspections and documenting the operating conditions of their equipment. They must utilize numerous power and hand tools so that they can perform all preventive maintenance and diagnose mechanical problems. Operations and maintenance technicians must also monitor the operation of plan equipment to ensure that employees are following the proper maintenance and safety procedures.

There are some key differences in the responsibilities of each position. For example, maintenance operator responsibilities require skills like "cdl," "dump truck," "dot," and "safety rules." Meanwhile a typical operations and maintenance technician has skills in areas such as "cleanliness," "windows," "cmms," and "mechanical maintenance." This difference in skills reveals the differences in what each career does.

Operations and maintenance technicians earn the highest salaries when working in the energy industry, with an average yearly salary of $60,926. On the other hand, maintenance operators are paid more in the energy industry with an average salary of $41,741.operations and maintenance technicians tend to reach similar levels of education than maintenance operators. In fact, operations and maintenance technicians are 0.9% more likely to graduate with a Master's Degree and 0.2% less likely to have a Doctoral Degree.Maintenance operator vs. Preventive maintenance technician

A preventive maintenance technician performs routine facility maintenance to prevent possible mechanical failure. The technicians change worn out machine parts before they can cause mechanical damage. They keep the facility operating. It is their job to conduct quality assessments, maintain inventory, and schedule repairs. Also, they see to it that machines are up and running at all times. They are expected to be equipped with skills in customer service, problem-solving, reading comprehension, business operation, and mechanical aptitude.

In addition to the difference in salary, there are some other key differences worth noting. For example, maintenance operator responsibilities are more likely to require skills like "cdl," "mowing," "safety procedures," and "dump truck." Meanwhile, a preventive maintenance technician has duties that require skills in areas such as "customer service," "dishwashers," "water filters," and "production equipment." These differences highlight just how different the day-to-day in each role looks.

On average, preventive maintenance technicians earn a higher salary than maintenance operators. Some industries support higher salaries in each profession. Interestingly enough, preventive maintenance technicians earn the most pay in the automotive industry with an average salary of $47,655. Whereas maintenance operators have higher pay in the energy industry, with an average salary of $41,741.In general, preventive maintenance technicians achieve similar levels of education than maintenance operators. They're 0.5% more likely to obtain a Master's Degree while being 0.2% less likely to earn a Doctoral Degree.Maintenance operator vs. Industrial maintenance mechanic

An industrial maintenance mechanic is responsible for ensuring the efficiency and optimal performance of industrial equipment and machinery to support operations and prevent operational delays. Industrial maintenance mechanics perform regular maintenance for the equipment, inspecting the components for any malfunctions, and conduct immediate repairs as needed. They also write resolution reports for reference and recommend supplies and resources to avoid the reoccurrence of system problems and downtimes. An industrial maintenance mechanic must have excellent organizational and analytical skills to measure and calibrate instruments properly and identify inconsistencies.

The required skills of the two careers differ considerably. For example, maintenance operators are more likely to have skills like "cdl," "preventative maintenance," "mowing," and "safety procedures." But a industrial maintenance mechanic is more likely to have skills like "production equipment," "conveyor systems," "production machines," and "cranes."

Industrial maintenance mechanics earn the best pay in the construction industry, where they command an average salary of $52,513. Maintenance operators earn the highest pay from the energy industry, with an average salary of $41,741.Most industrial maintenance mechanics achieve a similar degree level compared to maintenance operators. For example, they're 0.4% more likely to graduate with a Master's Degree, and 0.2% more likely to earn a Doctoral Degree.Maintenance operator vs. Facility maintenance technician

A facility maintenance technician is responsible for inspecting the safety and security of the facilities, including the operational tools, equipment, and machinery, to avoid potential hazards in the production area and maintain timely project deliverables. Facility maintenance technicians perform a regular check on the equipment, identifying glitches and inconsistencies, and repairing defective components to avoid delays in operation. They also install and assemble new machines, requiring them to have comprehensive knowledge of reading schematics and blueprints. A facility maintenance technician records incident reports and suggests immediate safety actions to management.

Even though a few skill sets overlap between maintenance operators and facility maintenance technicians, there are some differences that are important to note. For one, a maintenance operator might have more use for skills like "preventative maintenance," "dump truck," "dot," and "equipment operation." Meanwhile, some responsibilities of facility maintenance technicians require skills like "customer service," "good communication," "minor maintenance," and "facility equipment. "

The manufacturing industry tends to pay the highest salaries for facility maintenance technicians, with average annual pay of $45,090. Comparatively, the highest maintenance operator annual salary comes from the energy industry.The average resume of facility maintenance technicians showed that they earn similar levels of education compared to maintenance operators. So much so that theyacirc;euro;trade;re 0.9% more likely to earn a Master's Degree and less likely to earn a Doctoral Degree by 0.2%.Types of maintenance operator

Updated January 8, 2025