What does a manual machinist do?

A manual machinist specializes in developing tools and components through machinery. To make this possible, they must perform research and analysis, understand blueprints and schematics, identify the client or project's needs, develop prototypes and test structures, and subject products into various quality assurance procedures. They may also enhance existing components by studying their specifications and implementing solutions against problem areas. Moreover, a manual machinist typically works in a team setting, which requires an active communication line for a smooth and efficient workflow.

Manual machinist responsibilities

Here are examples of responsibilities from real manual machinist resumes:

- Measure and assemble sewing control panel frames of various material (stainless steel, carbon and aluminum).

- Set up and operation of Bridgeport mills, lathes and surface grinders to produce details for precision ball screw assemblies.

- Complete fabrication and machine shop work with MIG, TIG and stick welders, manual and CNC mills and lathes.

- Operate towmotor, and mig welder

- Perform quality GTAW welding in various positions.

- Start working for SKF in 2010 and are introduced the aerospace industry.

- Set up and run CNC Daewoo lathes with live tooling and bar feeders.

- Operate fabrication tools including MIG welder, plastic welder, and oxygen/acetylene torch.

- Utilize math skills to make calculations relate to machining, fabrication and assembly operations.

- Manufacture castings, gear box housings and forgings, and other aerospace and helicopter parts.

- Perform manual and automate (TIG) welding on production parts and custom make machinery.

- Work in manual machining area to do short runs, MIG weld fixtures and repair them.

- Machine parts to specifications, using machine tools, such as lathes, milling machines, boring bar, and grinders.

- Square all material for CNC operators, keep track or material, run CNC now and again when need.

- Set up various fixtures, vices, and molds, in the CNC mill as well as indicating when need.

Manual machinist skills and personality traits

We calculated that 10% of Manual Machinists are proficient in Grinders, Calipers, and CNC. They’re also known for soft skills such as Analytical skills, Manual dexterity, and Math skills and computer application experience.

We break down the percentage of Manual Machinists that have these skills listed on their resume here:

- Grinders, 10%

Machined parts to specifications, using machine tools, such as lathes, milling machines, boring bar, and grinders.

- Calipers, 10%

Machined parts to specific calibrated dimensions and tolerances, using instruments such as micrometers and vernier calipers.

- CNC, 10%

Set up various fixtures, vices, and molds, in the CNC mill as well as indicating when needed.

- ID, 5%

Cut length, OD, ID, threads, dovetails, and slots in various tubes and rods.

- Machine Shop, 5%

Perform routine scheduled preventive maintenance on all machine shop machinery.

- Hand Tools, 5%

Used measuring devices and various hand tools to complete each job and to maintain a high level of quality.

"grinders," "calipers," and "cnc" are among the most common skills that manual machinists use at work. You can find even more manual machinist responsibilities below, including:

Analytical skills. To carry out their duties, the most important skill for a manual machinist to have is analytical skills. Their role and responsibilities require that "machinists and tool and die makers must be able to interpret technical blueprints, models, and specifications so that they can craft precision tools and metal parts." Manual machinists often use analytical skills in their day-to-day job, as shown by this real resume: "measured tolerances with various tools including micrometers, calipers, gauge pins, dial indicators, tool analyzers and comparators. "

Manual dexterity. Another essential skill to perform manual machinist duties is manual dexterity. Manual machinists responsibilities require that "machinists’ and tool and die makers’ work demands accuracy, sometimes to within .0001 of an inch." Manual machinists also use manual dexterity in their role according to a real resume snippet: "operate overhead crane, forklift, band saw, manual lathe and measuring equipment. "

Mechanical skills. For certain manual machinist responsibilities to be completed, the job requires competence in "mechanical skills." The day-to-day duties of a manual machinist rely on this skill, as "machinists and tool and die makers may operate milling machines, lathes, grinders, laser and water jetting machines, wire electrical discharge machines, and other machine tools." For example, this snippet was taken directly from a resume about how this skill applies to what manual machinists do: "perform routine maintenance on machinery to preserve production and prevent downtime from mechanical failure. "

Physical stamina. A commonly-found skill in manual machinist job descriptions, "physical stamina" is essential to what manual machinists do. Manual machinist responsibilities rely on this skill because "machinist and tool and die makers must stand for extended periods and perform repetitious movements." You can also see how manual machinist duties rely on physical stamina in this resume example: "verified material identification, contents and physical characteristics to ensure proper receipt identity. "

Technical skills. Lastly, "technical skills" is an important element of what a manual machinist does. Manual machinist responsibilities require this skill because "machinists and tool and die makers must understand metalworking processes." This resume example highlights how manual machinist duties rely on this skill: "machined custom parts using manual mills and lathes delivered completed products within an ideal time frame programmed hitachi cnc lathe technical skills"

The three companies that hire the most manual machinists are:

- MAGELLAN AEROSPACE HAVERHILL10 manual machinists jobs

- Express Employment Indy South10 manual machinists jobs

- Aerotek5 manual machinists jobs

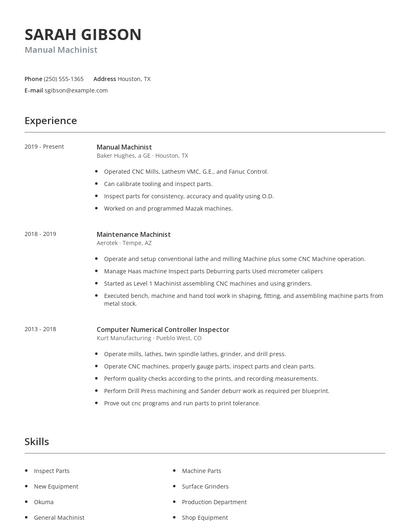

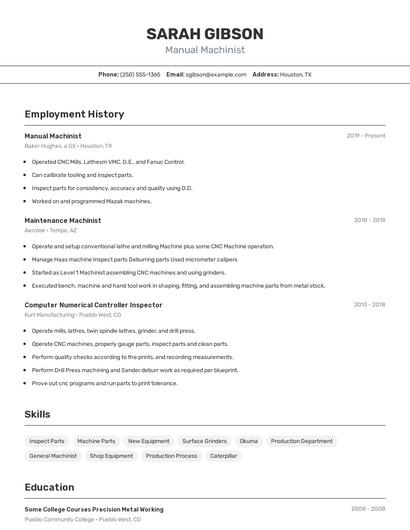

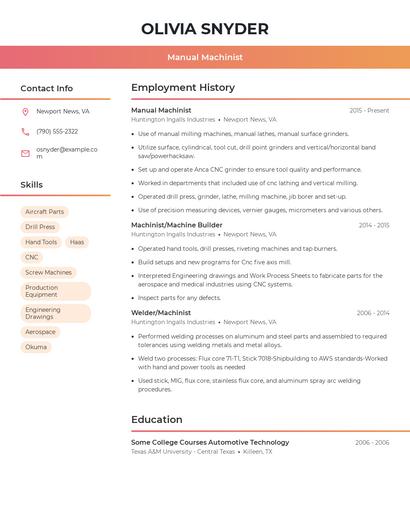

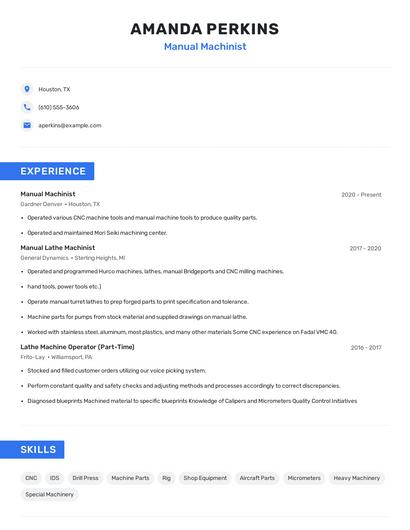

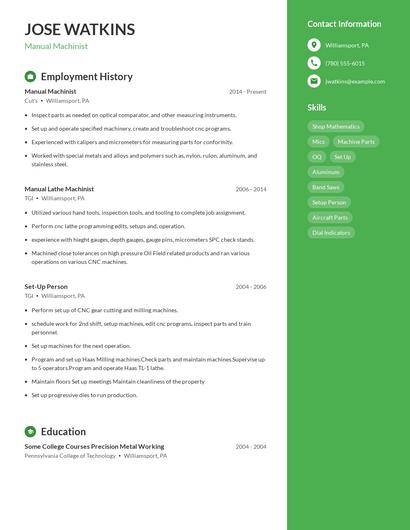

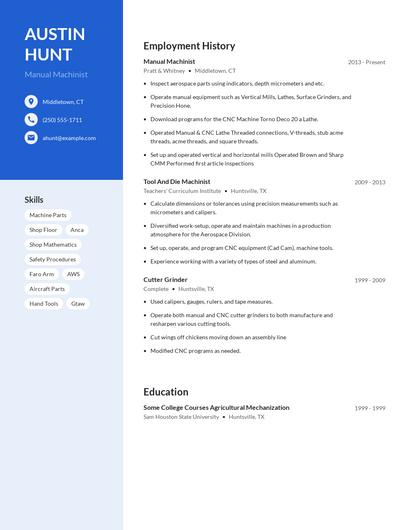

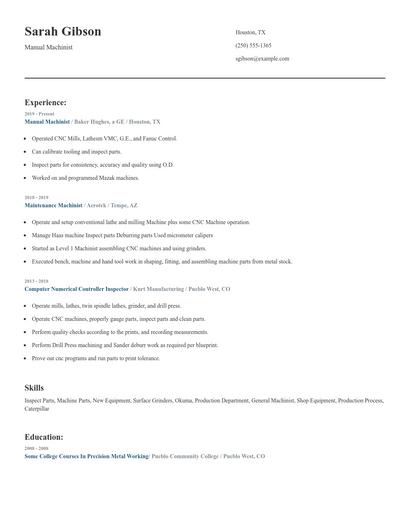

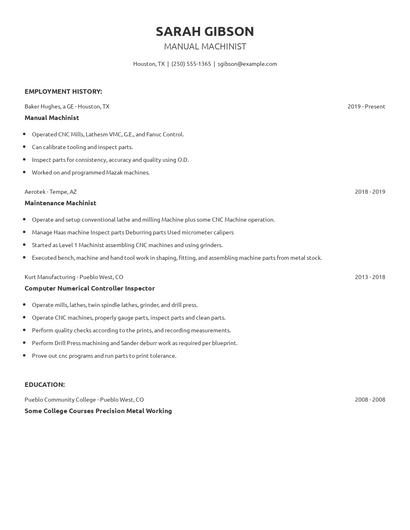

Choose from 10+ customizable manual machinist resume templates

Build a professional manual machinist resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your manual machinist resume.Compare different manual machinists

Manual machinist vs. Tool technician

Tool technicians are skilled professionals who are responsible for repairing a variety of pneumatic and hand tools as well as disassemble defective electrical equipment in a manufacturing firm using these hand tools. These technicians are required to coordinate with other areas of the company to schedule and perform preventive maintenance duties. They must provide support for CNC operators by setting up the caliper and micrometer of all the CNC machines. Tool technicians must also assist coworkers in ordering materials and purchasing machine parts.

While similarities exist, there are also some differences between manual machinists and tool technician. For instance, manual machinist responsibilities require skills such as "id," "math," "manual machines," and "cranes." Whereas a tool technician is skilled in "first hand," "micrometers," "injection molds," and "edm." This is part of what separates the two careers.

Tool technicians earn the highest salaries when working in the energy industry, with an average yearly salary of $64,215. On the other hand, manual machinists are paid more in the technology industry with an average salary of $49,950.On average, tool technicians reach similar levels of education than manual machinists. Tool technicians are 1.1% more likely to earn a Master's Degree and 0.2% less likely to graduate with a Doctoral Degree.Manual machinist vs. Grinder

Depending on the industry, a grinder has a diverse range of duties. Typically, they oversee setting up and operating bearing grinders, cam grinders, and CNC lathes. A grinder must meet with the manufacturer's specifications by making use of shop drawings. Additionally, they may be tasked with repairing any mechanical breakdowns on the machines.

Each career also uses different skills, according to real manual machinist resumes. While manual machinist responsibilities can utilize skills like "id," "manual machines," "cranes," and "horizontal boring mills," grinders use skills like "grinding wheels," "safety procedures," "quality standards," and "grinding tools."

Grinders earn a lower average salary than manual machinists. But grinders earn the highest pay in the automotive industry, with an average salary of $40,459. Additionally, manual machinists earn the highest salaries in the technology with average pay of $49,950 annually.grinders earn similar levels of education than manual machinists in general. They're 0.2% less likely to graduate with a Master's Degree and 0.2% less likely to earn a Doctoral Degree.Manual machinist vs. Machinist/machine builder

A computer numerical controller machinist is responsible for operating computer-based equipment, creating new machine components by programming, and evaluating machine blueprints. Computer numerical controller machinists must have extensive knowledge of the technology industry to understand its complexities and define accurate solutions, as well as excellent analytical skills for calculation requirements. Other tasks include interpreting specifications and parameters, monitoring stock inventory, requesting operating tools, verifying accurate measurements, detecting machine malfunctions, and adhering to the safety standards and procedures of the operations area.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from manual machinist resumes include skills like "cnc," "machine shop," "math," and "drill press," whereas a machinist/machine builder is more likely to list skills in "micrometers," "manual lathes," "cnc mill," and "haas. "

When it comes to education, machinist/machine builders tend to earn similar degree levels compared to manual machinists. In fact, they're 1.4% less likely to earn a Master's Degree, and 0.5% less likely to graduate with a Doctoral Degree.Manual machinist vs. Computer numerical controller machinist

Types of manual machinist

Updated January 8, 2025