What does a material analyst do?

A materials analyst is responsible for managing the assets and materials of an organization, ensuring the adequacy of office inventories to support business operational functions. Materials analysts identify cost-reduction materials by coordinating with trusted suppliers and third-party vendors. They handle the distribution of goods and order processes according to the company's supply chain management. A materials analyst must have excellent organizational and analytical skills, especially in conducting data and statistical analysis to obtain high-quality materials that would meet the customers' demands.

Material analyst responsibilities

Here are examples of responsibilities from real material analyst resumes:

- Manage over 120 raw materials on KanBan and daily delivery systems.

- Create and manage MPS (master production schedule) for MAU factory.

- Manage and expedite delivery to ensure on time delivery (OTD) to customer.

- Communicate with suppliers and MRO's on a regular basis to manage projects and ensure customer satisfaction.

- Manage WIP inventory into/out of multiple distribution plant locations.

- Experience in integrate logistics and manage hardware material requirements to support production programs that exceed productivity goals.

- Conduct annual inventory of warehouse materials, and reconcile balances with cycle counts for the ERP system.

- Utilize ERP software to maintain inventory accuracy.

- Analyze production and inventory levels using MRP and JIT principles for component procurement in a lean manufacturing environment.

- Establish, track and control various KPI for the area.

- Organize and maintain a KANBAN visual inventory system utilizing TPS and JIT.

- Track shipments from vendors to expedite materials as needed by field offices for timely installation.

- Coordinate the physical inventory of materials and supplies in compliance with Sarbanes Oxley (SOX) guidelines.

- Attend weekly ECO meetings so that as parts are changed, vendors can be update as well as purchasing records.

- Create end items and spare parts demand to support enterprise business needs through forecasting and firm orders for MPS items.

Material analyst skills and personality traits

We calculated that 17% of Material Analysts are proficient in Supply Chain, Logistics, and MRP. They’re also known for soft skills such as Critical-thinking skills, Customer service skills, and Organizational skills.

We break down the percentage of Material Analysts that have these skills listed on their resume here:

- Supply Chain, 17%

Conducted cross departmental meetings for productive material availability and balanced the Demand and Supply between Mechanical and Supply Chain management team.

- Logistics, 7%

Provided enthusiastic support to Logistics Supervisory team, District Managers and Field Representatives to ensure proper procedural function is maintained.

- MRP, 7%

Analyzed production and inventory levels using MRP and JIT principles for component procurement in a lean manufacturing environment.

- Continuous Improvement, 4%

Assist in investigation of inventory discrepancies found and implement corrective action plans for continuous improvement of inventory process.

- Part Numbers, 4%

Contracted through Superior Technical Resources Research of part numbers and inventory data for a number on International Corporations.

- Purchase Orders, 4%

Initiate factory orders and purchase orders for the manufacture of products to meet customer requirements and maintain established inventory levels.

Common skills that a material analyst uses to do their job include "supply chain," "logistics," and "mrp." You can find details on the most important material analyst responsibilities below.

Critical-thinking skills. To carry out their duties, the most important skill for a material analyst to have is critical-thinking skills. Their role and responsibilities require that "logisticians must develop, adjust, and carry out logistical plans." Material analysts often use critical-thinking skills in their day-to-day job, as shown by this real resume: "gained first time, hands-on experience in the supply chain industry, which enabled development of analytical and critical-thinking skills. "

Customer service skills. Another soft skill that's essential for fulfilling material analyst duties is customer service skills. The role rewards competence in this skill because "logisticians must know the needs of their customers in order to coordinate the movement of materials between suppliers and customers." According to a material analyst resume, here's how material analysts can utilize customer service skills in their job responsibilities: "participate in cross-functional team, and individual projects to deliver process improvements across purchasing services. "

Organizational skills. This is an important skill for material analysts to perform their duties. For an example of how material analyst responsibilities depend on this skill, consider that "logisticians must be able to keep detailed records and simultaneously manage several projects in a fast-paced environment." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a material analyst: "created various databases for purchasing department and for the organizational wide use of capturing supplier performance and quality. ".

Problem-solving skills. material analyst responsibilities often require "problem-solving skills." The duties that rely on this skill are shown by the fact that "logisticians must handle unforeseen issues, such as delivery problems, and adjust plans as needed to resolve the issues." This resume example shows what material analysts do with problem-solving skills on a typical day: "facilitated problem resolutions with accounts payable related to purchase orders/invoicing and pricing. "

Communication skills. Another common skill required for material analyst responsibilities is "communication skills." This skill comes up in the duties of material analysts all the time, as "logisticians need strong communication skills to collaborate with colleagues and do business with suppliers and customers." An excerpt from a real material analyst resume shows how this skill is central to what a material analyst does: "maintained close communication with manufacturing by providing updated documentation for part delivery dates on system issues boards. "

The three companies that hire the most material analysts are:

- ManpowerGroup13 material analysts jobs

- Polaris11 material analysts jobs

- RRD11 material analysts jobs

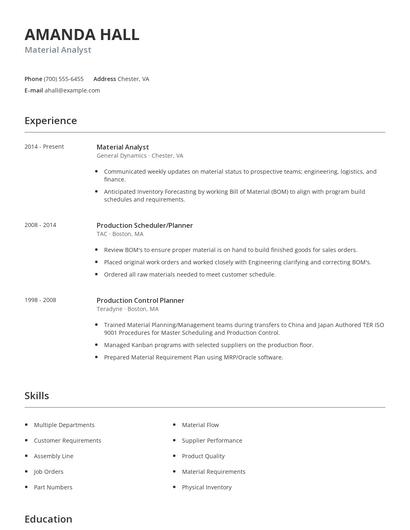

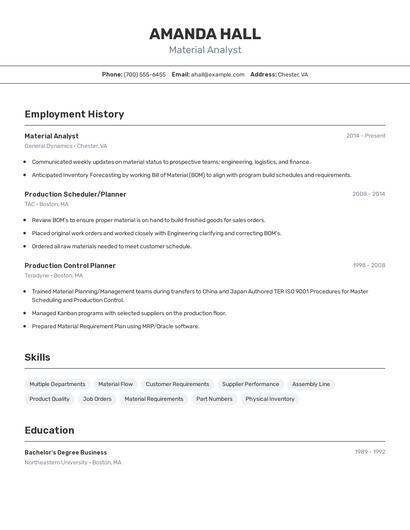

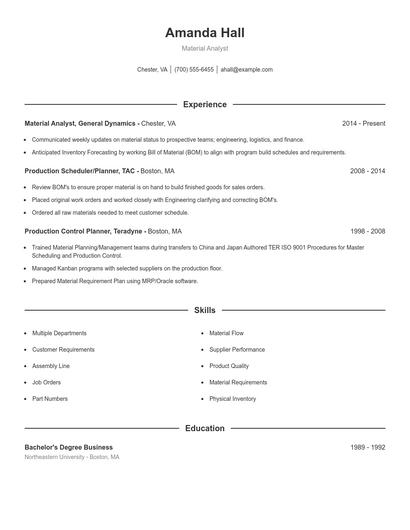

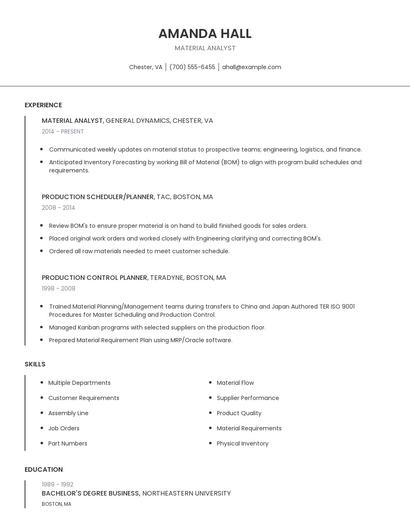

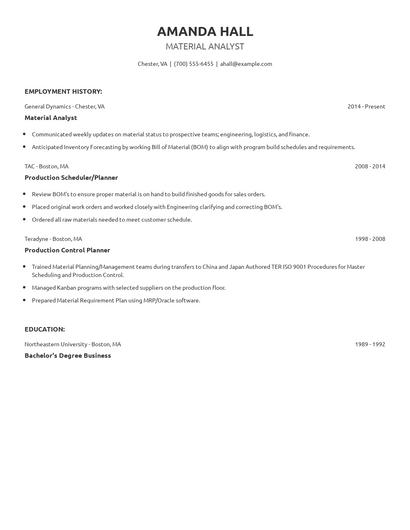

Choose from 10+ customizable material analyst resume templates

Build a professional material analyst resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your material analyst resume.Compare different material analysts

Material analyst vs. Senior buyer

The job of senior buyers, or also known as purchasing agents, is to meet the material needs of an organization. They are responsible for finding suppliers, arranging the distribution to several retail outlets, and supervising other purchasing agents. They also look for new product streams and establish procurement strategies. Senior buyers typically begin their careers as assistant buyers or junior purchasing agents. Most employers usually prefer those with college degrees in marketing, business, and economics.

While similarities exist, there are also some differences between material analysts and senior buyer. For instance, material analyst responsibilities require skills such as "part numbers," "corrective action," "excellent interpersonal," and "material availability." Whereas a senior buyer is skilled in "commodities," "customer service," "cost reduction," and "product development." This is part of what separates the two careers.

Senior buyers really shine in the hospitality industry with an average salary of $81,144. Comparatively, material analysts tend to make the most money in the automotive industry with an average salary of $68,903.On average, senior buyers reach similar levels of education than material analysts. Senior buyers are 0.2% less likely to earn a Master's Degree and 0.1% more likely to graduate with a Doctoral Degree.Material analyst vs. Supply chain coordinator

A supply chain coordinator is an individual who is responsible for managing inventory and supply sources to support a company's manufacturing and anticipated demand. Supply chain coordinators must assist in the purchase of materials and services and follow-up with vendors to ensure that the purchase orders have the correct price, freight charge, and delivery date. They coordinate with the quality assurance (QA) inspectors to ensure the quality of the purchased parts and services. Under the directive orders from the logistics manager, supply chain coordinators must also perform inventory cycle counts.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that material analyst responsibilities requires skills like "part numbers," "excellent interpersonal," "material availability," and "material flow." But a supply chain coordinator might use other skills in their typical duties, such as, "customer service," "chain management," "project management," and "data entry."

Supply chain coordinators earn a lower average salary than material analysts. But supply chain coordinators earn the highest pay in the manufacturing industry, with an average salary of $57,806. Additionally, material analysts earn the highest salaries in the automotive with average pay of $68,903 annually.supply chain coordinators earn similar levels of education than material analysts in general. They're 1.1% more likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.Material analyst vs. Contracts administrator

Contract administrators create and manage legal contracts from which the company participates. They ensure that all entities to the contract will accomplish their obligations, as indicated in the contract. They usually work for larger organizations that might be involved with different or highly complex contracts. These organizations spread across a range of industries, including government, construction, and healthcare. Their responsibilities include addressing any conflicts of questions regarding the contract, analyzing the possible risks posed by contracts, and working alongside the legal and procurement teams.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from material analyst resumes include skills like "supply chain," "logistics," "mrp," and "continuous improvement," whereas a contracts administrator is more likely to list skills in "contract administration," "customer service," "contract management," and "proposal preparation. "

Contracts administrators earn the highest salary when working in the finance industry, where they receive an average salary of $72,687. Comparatively, material analysts have the highest earning potential in the automotive industry, with an average salary of $68,903.Most contracts administrators achieve a similar degree level compared to material analysts. For example, they're 1.2% more likely to graduate with a Master's Degree, and 3.0% more likely to earn a Doctoral Degree.Material analyst vs. Production scheduler

A production scheduler is in charge of developing manufacturing schedules to achieve short and long term production goals. Their responsibilities typically revolve around performing research and analysis to understand the extent of all procedures, identifying the needs of clients, and devising strategies for optimal operations. They must also monitor the company's resources and workforce to ensure that everything runs smoothly in adherence to all schedules, making changes only when necessary. Furthermore, as a production scheduler, it is essential to encourage the workforce to reach goals and deadlines, all while implementing the company's policies and regulations.

Types of material analyst

Updated January 8, 2025