What does a material coordinator do?

A material coordinator is in charge of processing requisitions and ensuring that all departments receive necessary goods and materials within a company. Aside from this, they must maintain positive engagements with vendors, suppliers, and business partners, negotiate contracts, manage schedules of deliveries, and prioritize cost-efficient goods. It is also a material coordinator's responsibility to keep an accurate record of inventory, secure sensitive data, and coordinate with all departments to ensure that all transactions are efficient and precise.

Material coordinator responsibilities

Here are examples of responsibilities from real material coordinator resumes:

- Manage the IUID (item unique identification) program direct by the DOD.

- Lead and execute projects relate to different commodities such as copper and silver, expect savings of $435K.

- Manage HazMat removals to ensure hazardous waste environmental compliance.

- Manage & coordinate logistics for shipments of product purchase and sell throughout the assigned region from manufacturer to country coordinator/sub.

- Develop a KanBan ordering system for warehouse supplies.

- Set up and support for KANBAN replenishment areas.

- Maintain the warehouse in compliance with OSHA safety standards.

- Handle billing materials update to meet production and ISO standards.

- Enter and edit material data from spool sheets using AS400 system.

- Help with all inventories by entering figures into AS400 on month end inventory.

- Work closely and effectively with vendors to troubleshoot issues and perform system upgrades.

- Maintain cleanliness and presentation of stock room and production floor job staging area.

- Ensure operations are in compliance with FAA as well as military specifications and requirements.

- Audit ship orders/pallets for accuracy, adjust inventory in WMS system, cycle count excess product

- Develop process to track, coordinate, and maintain departmental procedures, records and GMP documentation.

Material coordinator skills and personality traits

We calculated that 9% of Material Coordinators are proficient in Logistics, Customer Service, and Purchase Orders. They’re also known for soft skills such as Communication skills, Customer-service skills, and Detail oriented.

We break down the percentage of Material Coordinators that have these skills listed on their resume here:

- Logistics, 9%

Confirm all material transactions to inventory via Clarify Clear Logistics inventory system including electronic back up and document hard copy.

- Customer Service, 8%

Provide exceptional customer service by communicating frequently with suppliers, carriers and vendor coordinators to ensure consistency in direction and expectations.

- Purchase Orders, 6%

Verified purchase orders and requisitions by comparing items requested to master list; clarifying unclear items and requesting alternatives.

- Inventory Control, 6%

Maintain and tracked proper inventory control using the company's inventory control system which include manufacturing materials and storeroom inventories.

- Production Schedules, 5%

Reviewed production schedules and related information, examined material delivered to production departments verified conformance to specifications, OS&D.

- Data Entry, 4%

Maintained and controlled all data entry to the Turnaround Database for accuracy and accountability purposes on major projects.

Most material coordinators use their skills in "logistics," "customer service," and "purchase orders" to do their jobs. You can find more detail on essential material coordinator responsibilities here:

Communication skills. To carry out their duties, the most important skill for a material coordinator to have is communication skills. Their role and responsibilities require that "material recording clerks are frequently in contact with suppliers, vendors, or managers and need to convey their company’s needs effectively." Material coordinators often use communication skills in their day-to-day job, as shown by this real resume: "received and logged new telecommunications equipment into erp database system. "

Customer-service skills. Many material coordinator duties rely on customer-service skills. "material recording clerks may interact with customers in order to respond to problems or complaints.," so a material coordinator will need this skill often in their role. This resume example is just one of many ways material coordinator responsibilities rely on customer-service skills: "ship finished goods, sub-assemblies, supplies and hazmat materials to customers. "

Detail oriented. material coordinators are also known for detail oriented, which are critical to their duties. You can see how this skill relates to material coordinator responsibilities, because "material and product inspecting clerks must pay attention to detail when checking items for defects, some of which are small and difficult to spot." A material coordinator resume example shows how detail oriented is used in the workplace: "generate work orders, new capital project codes, subcontractor detail and other critical data entry. "

Math skills. A big part of what material coordinators do relies on "math skills." You can see how essential it is to material coordinator responsibilities because "material recording clerks may need to calculate shipping costs or take measurements." Here's an example of how this skill is used from a resume that represents typical material coordinator tasks: "experienced dealing with a great quantity of sku s or part numbers.has excellent math skills. "

The three companies that hire the most material coordinators are:

- Applied Materials121 material coordinators jobs

- Sheridan28 material coordinators jobs

- Kiewit11 material coordinators jobs

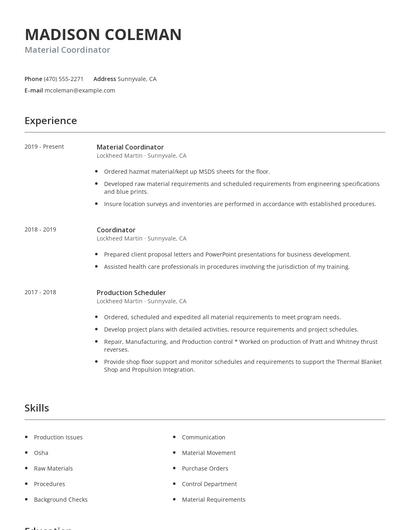

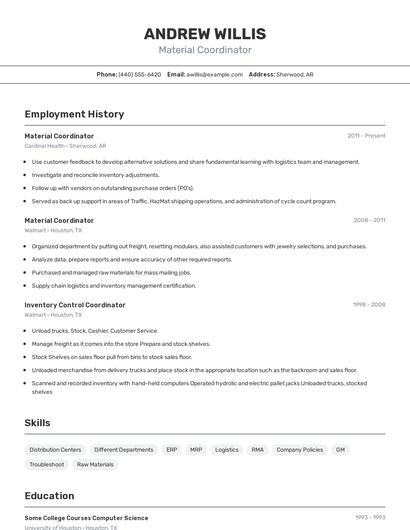

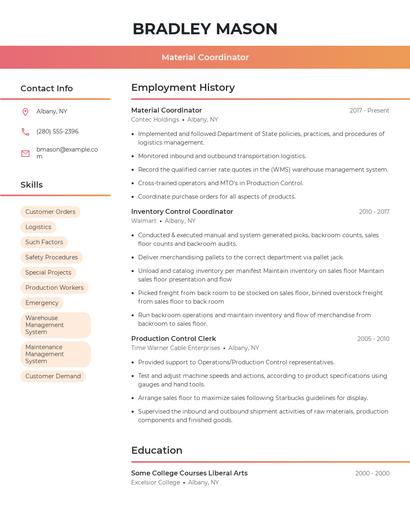

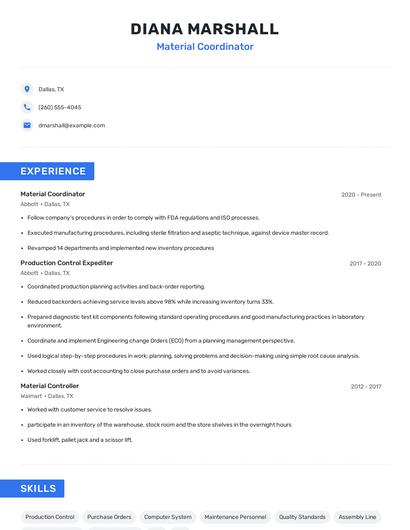

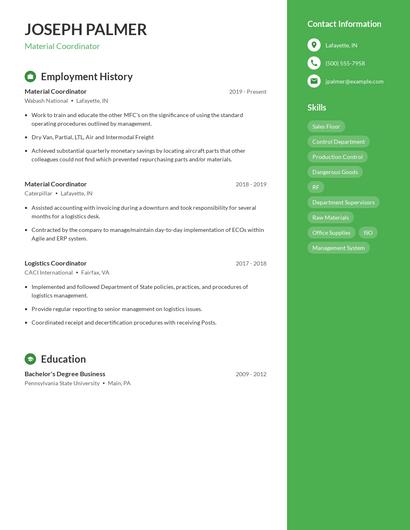

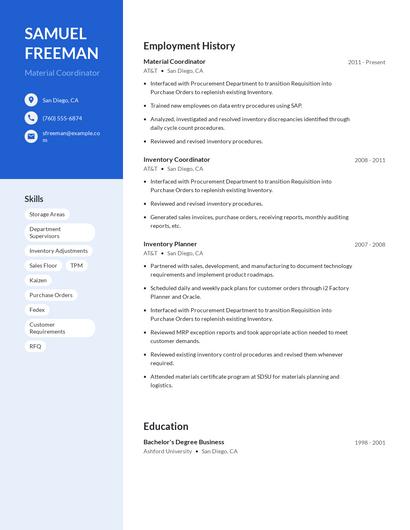

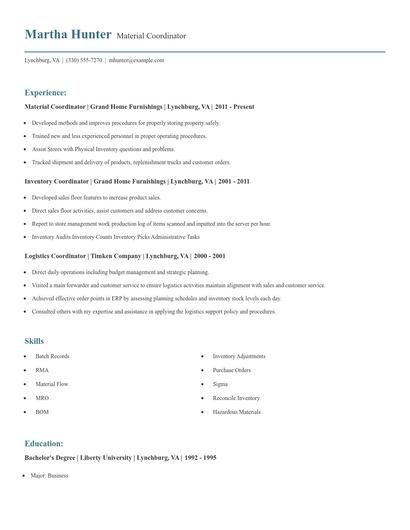

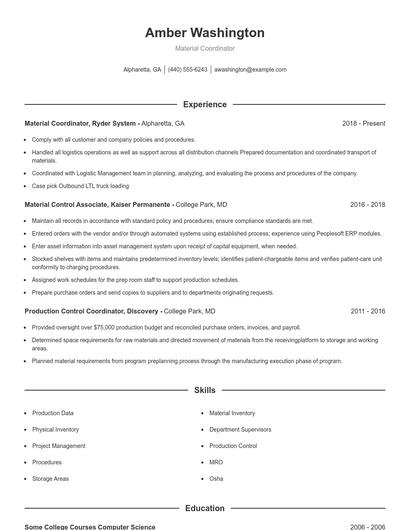

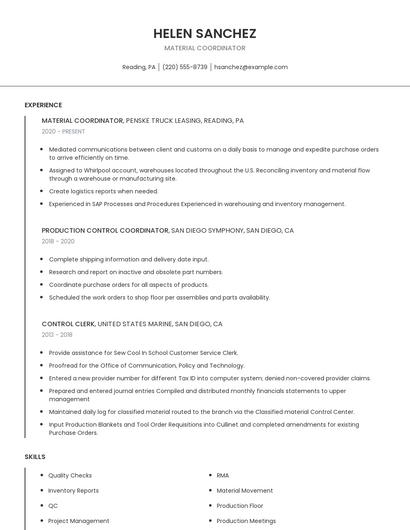

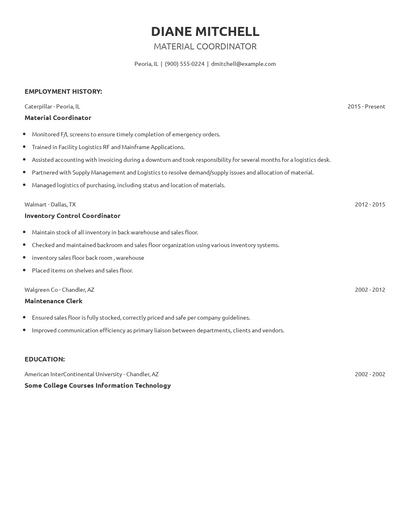

Choose from 10+ customizable material coordinator resume templates

Build a professional material coordinator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your material coordinator resume.Compare different material coordinators

Material coordinator vs. Production planner

Production planners or schedulers are employees who take charge of the timeliness and accuracy of the production process. The planners develop production schedules which detail the tasks that need to be done to meet the set completion date. They emphasize the goods and materials necessary in the production phase. It is their job to make sure that the working space is well-maintained for optimal performance. They also manage the flow of information during production.

There are some key differences in the responsibilities of each position. For example, material coordinator responsibilities require skills like "production schedules," "data entry," "shipping receiving," and "material inventory." Meanwhile a typical production planner has skills in areas such as "continuous improvement," "on-time delivery," "lean manufacturing," and "shop floor." This difference in skills reveals the differences in what each career does.

Production planners earn the highest salaries when working in the energy industry, with an average yearly salary of $64,353. On the other hand, material coordinators are paid more in the finance industry with an average salary of $41,571.production planners tend to reach similar levels of education than material coordinators. In fact, production planners are 2.4% more likely to graduate with a Master's Degree and 0.1% more likely to have a Doctoral Degree.Material coordinator vs. Logistics clerk

Logistics clerks are professionals who are responsible for regulating the supply chain of an organization by performing administrative tasks such as monitoring inventory levels, arranging transportation methods, and managing shipping schedules. These clerks are required to ensure that electronic or paper files are kept accurately and up-to-date so that they can track orders and answer billing questions. They must assist in inspecting orders that arrived in their facility so that they can identify damage and input information into their inventory records. Logistic clerks must also handle replacement for incorrect or damaged goods.

Each career also uses different skills, according to real material coordinator resumes. While material coordinator responsibilities can utilize skills like "logistics," "mrp," "material inventory," and "material flow," logistics clerks use skills like "outbound shipments," "freight bills," "delivery schedules," and "rf."

On average, logistics clerks earn a lower salary than material coordinators. Some industries support higher salaries in each profession. Interestingly enough, logistics clerks earn the most pay in the manufacturing industry with an average salary of $35,696. Whereas material coordinators have higher pay in the finance industry, with an average salary of $41,571.logistics clerks earn similar levels of education than material coordinators in general. They're 1.6% less likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.Material coordinator vs. Supply technician

In a warehouse setting, a supply technician is responsible for handling all the incoming and outgoing products, ensuring accuracy in inventory and logistics. Most of the time, they are in charge of maintaining and keeping records, loading and unloading shipments and deliveries, verifying invoices, and processing documents. A supply technician often works under the supervision of a manager or supervisor, and it is essential to report any complicated issues that need to be resolved. Furthermore, one must adhere to the policies and regulations and maintain a safe environment for everyone.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from material coordinator resumes include skills like "logistics," "production schedules," "cycle counts," and "mrp," whereas a supply technician is more likely to list skills in "patients," "rehabilitation," "storage management," and "dod. "

Supply technicians earn the best pay in the technology industry, where they command an average salary of $50,167. Material coordinators earn the highest pay from the finance industry, with an average salary of $41,571.When it comes to education, supply technicians tend to earn similar degree levels compared to material coordinators. In fact, they're 0.1% less likely to earn a Master's Degree, and 0.0% less likely to graduate with a Doctoral Degree.Material coordinator vs. Supply specialist

A supply specialist is responsible for monitoring the adequacy of equipment and supplies, including quality maintenance and securing storage of merchandise. Supply specialists manage order requests, verify shipment details, and perform data entry tasks such as updating the database for incoming and outgoing supplies. They should be highly analytical, inspecting the items for any defects and malfunctions, and immediately processing replacement and new stock issuance. A supply specialist should follow the safety protocols at all times to avoid operational hazards and any possible delays.

Types of material coordinator

Updated January 8, 2025