Automatically apply for jobs with Zippia

Upload your resume to get started.

Material lead skills for your resume and career

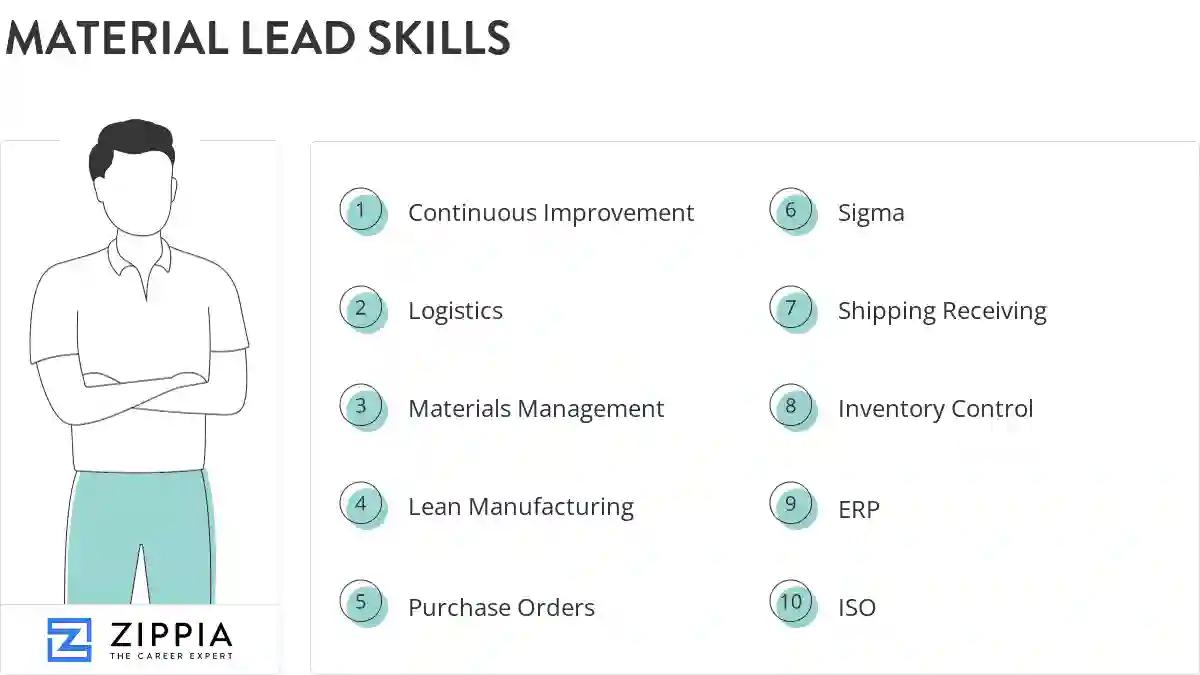

15 material lead skills for your resume and career

1. Continuous Improvement

Continuous improvement is an ongoing process of improvement of products, services, and processes with the help of innovative ideas. It is an organized approach that helps an organization to find its weaknesses and improve them.

- Contribute to company's continuous improvement processes.

- Recommended courses of action to understand and prevent future occurrences of issues driving continuous improvement.

2. Logistics

Logistics is a complete organization and implementation of a problem. Logistics are often considered in a complex business operation, as some works need detailed plannings. Logistics are also used in military action.

- Provided technical judgments, recommendations, & leadership on hardware/software & for logistics applications.

- Resolved potential supply constraints, executed logistics for initial stock level strategy.

3. Materials Management

Materials management refers to the process of monitoring and controlling the inventory and use of materials, often within a manufacturing plant. This management may also require shipping and delivery of the materials depending on the material product, price, and customer demand.

- Established Site Materials Management and Site Preservation Plans.

- Created and implemented global share point site and weekly reviews of 27 global facilities' materials management goals and performance.

4. Lean Manufacturing

- Input & maintain MRP to ensure lean manufacturing and synchronous production flow to level-load the manufacturing facility.

- Increased production & streamlined processes through lean manufacturing concepts.

5. Purchase Orders

- Work with accounting department to ensure accuracy of purchase order information.

- Updated systems with day-to-day information, routine tasks of incoming and outgoing purchase orders, and produced bin tickets for delivery.

6. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Gained an extensive knowledge of the DMAIC and 5 S's of Six Sigma processes for improving quality.

- Sponsored 2 Six Sigma projects.

Choose from 10+ customizable material lead resume templates

Build a professional material lead resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your material lead resume.7. Shipping Receiving

- Managed purchasing, production/inventory control, Shipping receiving and warehouse departments for two separate manufacturing locations.

- Manage materials group; shipping receiving; put away and 5S functions.

8. Inventory Control

- Located missing valves sent out without documentation Skills Used Data management Investigation Microsoft Office skills Inventory control procedures

- Developed complex spreadsheets and databases utilized in material planning process and inventory control.

9. ERP

Enterprise Resource Planning (ERP) is computer software used by major corporations and organizations for conducting their management and accounting tasks efficiently. ERP systems bind different business processes with each other allowing smoother flow of data between them resulting in swift project assessment and completion.

- Deployed to Strategic Systems Programs (SSP) at Washington Navy Yard in support of Navy ERP implementation.

- Developed an intuitive tool that integrates Oracle ERP and Excel for supply and demand requirements.

10. ISO

- Maintained material certification in accordance with ISO standards.

- Shared audit information at weekly PVR and Material Yield meetings Assisted in development of new policies and procedures per ISO regulation.

11. MRP

MRP is an abbreviation of Material Requirements Planning and refers to the control system which is implemented in the planning and management of the activities related to manufacturing. Through MRP, manufacturers can easily schedule the production and it can also be used for inventory. MRP systems are mostly software-based but the process can also be carried out manually.

- Controlled inventory, staying within and below MRP requirements

- Maintain production plan based on forecast and Master Schedule Develop material plans based upon the master schedule and MRP.

12. Material Flow

Material flow refers to the transportation of raw materials, components, work-in-progress inventory, integrated objects, and final products flowing from one place to the other to get integrated or delivered. This plays a significant role in the functioning of supply chain management. It is possible through warehouses among distributors, retailers, and dealers.

- Managed a small sub-set of suppliers to help understand the supply chain implication of material flow.

- Developed and implemented processes to ensure efficient material flow from receipt to ship.

13. Material Planning

Material Planning refers to the act of planning what materials may be needed for a particular project or for consumers. This is a form of inventory management so that consumers and developers are able to have access to the raw materials needed for a project or store inventory.

- Provided training, guidance and advice on all aspects of material planning and production scheduling to staff of 12 Mexican Nationals.

- Executed field procurement, material planning/receiving/issuing, warehousing, invoice approval, progress reporting, and purchase order closeout.

14. OSHA

- Lead and facilitated implementation of mandatory OSHA GHS Labeling initiative.

- Enforced 5-S Program and OSHA Safety Regulations.

15. Cost Reduction

- Negotiated contracts with suppliers to meet material cost targets and pursued cost reduction opportunities by looking for alternate material or suppliers.

- Worked on cross referencing OEM manuals to find parts more readily available and at a cost reduction.

5 Material Lead resume examples

Build a professional material lead resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your material lead resume.

What skills help Material Leads find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of material lead skills to add to your resume

The most important skills for a material lead resume and required skills for a material lead to have include:

- Continuous Improvement

- Logistics

- Materials Management

- Lean Manufacturing

- Purchase Orders

- Sigma

- Shipping Receiving

- Inventory Control

- ERP

- ISO

- MRP

- Material Flow

- Material Planning

- OSHA

- Cost Reduction

- BOM

- Kanban

- Lean Six Sigma

- Material Handlers

- Cost Savings

- Management System

- Customer Orders

- OTD

- Production Planning

- Cycle Counts

- Production Lines

- Commodities

- DOT

- Process Improvement

- MRO

- Inventory Reduction

- Direct Reports

- Production Schedules

- Strategic Sourcing

- Warehouse Operations

- FDA

- Quality Issues

- Production Control

- Manage Inventory

- Value Stream

- NPI

- QC

- KPI

- Global Sourcing

- Maximo

- Production Floor

- JIT

Updated January 8, 2025