Automatically apply for jobs with Zippia

Upload your resume to get started.

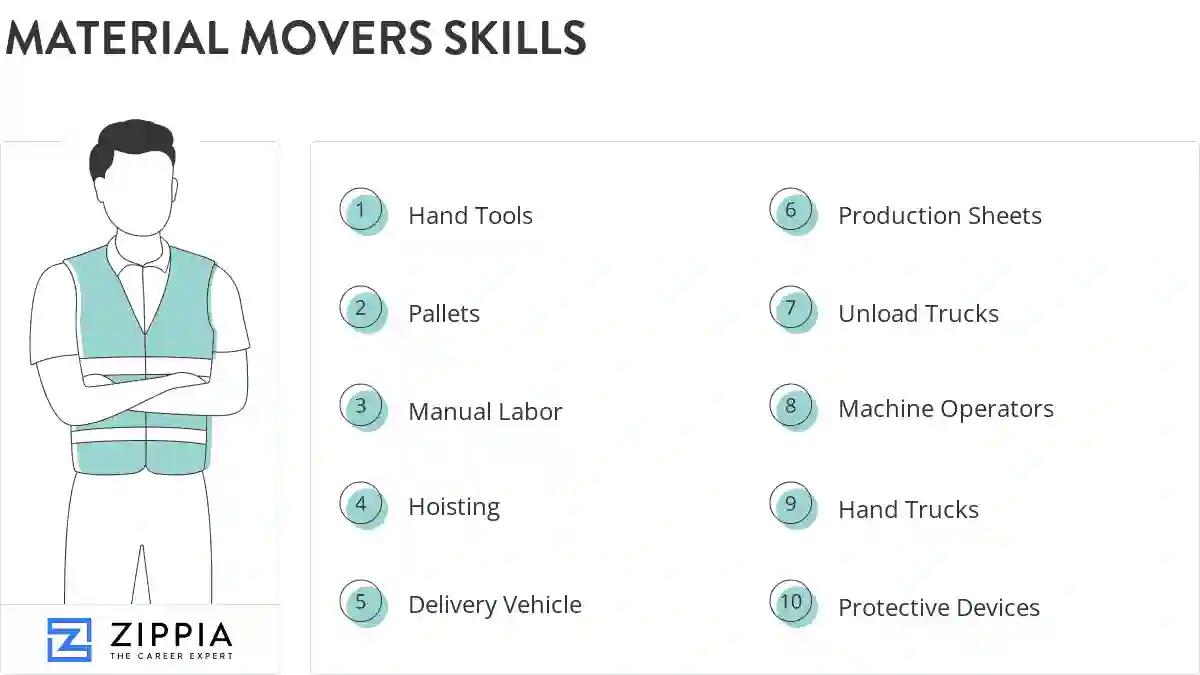

Material movers skills for your resume and career

15 material movers skills for your resume and career

1. Hand Tools

- Adjust and replace equipment parts, such as rollers, belts, plugs and caps, using hand tools.

- Cleaned containers, materials, supplies, and work areas, using cleaning solutions and hand tools.

2. Pallets

- Remove packaging and place pump on wood pallets using a pressurized lifter.

- Move material safely within the warehouse with forklift and pallet jack.

3. Manual Labor

Any kind of work that is carried out by workers manually instead of using machines is termed manual labor.

- Include all unskilled manual laborers not elsewhere classified.Duties: Various temporary labor jobs

- Operated machinery and performed manual labor functions to move cargo.

4. Hoisting

- Loaded and unloaded ship cargo, using winches and other hoisting device Maintained high standards of excellence.

- Started hoisting device that raises refuse bin attached to rear of truck.

5. Delivery Vehicle

A delivery vehicle is a means of transport used to deliver all kinds of products. Semi-trailers on land are equipped with a variety of trailers, including box trailers, flatbeds, and other modified trailers, whereas railroad trains have similar specialized cars. Merchant ships on the sea come in a variety of shapes and sizes. Cargo is delivered by freight planes.

- Loaded docks, delivery vehicles, and containers, by hand or using trucks, tractors, or other equipment.

- Loaded boxes onto delivery vehicles by utilizing a hand truck.

6. Production Sheets

- Counted, weighed, and recorded number of units of materials moved or handled on daily production sheet.

- Record numbers of units handled or moved, using daily production sheets or work tickets.

Choose from 10+ customizable material movers resume templates

Build a professional material movers resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your material movers resume.7. Unload Trucks

Unload trucks is an activity that is undertaken to remove items that have been carried on a truck. It could be raw materials, work-in-stock or finished products. Unloading a truck may require people and some equipment that may help unload items that are too heavy or dangerous for humans to handle.

- Load trucks or unload trucks work in warehouse at the yard or go on pack jobs.

- Load and unload trucks move freight, stock or other materials.

8. Machine Operators

Machine operators, also known as machinists, refer to workers responsible for various machines with specific functions. Their duties include setting up equipment, loading materials, and operating machinery. The machine operators also monitor and optimize their operations for efficiency.

- Operate forklift used in the production process, or assist machine operators.

- Distributed confidential client information, confirmations and statements to designated mail machines and machine operators.

9. Hand Trucks

Hand trucks are also known as a dolly or a two wheeler is an L-shaped, box moving, handcart. The hand truck has two big wheels on one side of the base and has a small ledge that holds the object to be moved. The hand truck is operated manually and has a handle that a person can use to load the boxes into the base and then unload it. It balances the weight of the objects and makes carrying heavy boxes easier.

- Transported receptacles to and from designated areas, by hand and using dollies, hand trucks and left equipment.

- Operate forklift, hand trucks and other mechanical equipment to carry out warehouse/store responsibilities.

10. Protective Devices

- Install protective devices, such as bracing, padding or strapping, to prevent shifting damage to items being transported.

- Installed protective devices,such as braces and padding to prevent materials from shifting while being moved.

11. Slings

- Attach slings, hooks, or other devices to lift cargo and guide loads.

- Attach slings, hooks, or other devices to lift cargo and guide loads.

12. Electrical Equipment

- Connect electrical equipment to power sources so that it can be tested before use.

13. Dollies

- Utilize material moving equipment such as pallet jacks, forklifts and dollies to bring products and materials to an appropriate location.

- Move property from one place to another with and without the use of pull carts, dollies, and pallet jacks.

14. Rig

Rigging includes designing, preparing, or setting up equipment for drilling operations. This skill is one of the main and most important activities in the oil and gas industry, whether it's for onboard operations or port operations. Rigging systems should have parts like master links, shackles, slings, and lifting bags for underwater lifting. Professionals working with rigging systems are responsible for tasks like operating platform lifts, forklifts, and overhead cranes.

- Rig or dismantle props or equipment, such as frames, scaffolding, platforms, or backdrops, using hand tools.

- Rig cargo for unloading/loading with cranes.

15. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Handle and process boxes through an assembly line to be compacted with tobacco and shipped across seas.

- Operated in boat fabrication assembly line.

5 Material Movers resume examples

Build a professional material movers resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your material movers resume.

What skills help Material Movers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of material movers skills to add to your resume

The most important skills for a material movers resume and required skills for a material movers to have include:

- Hand Tools

- Pallets

- Manual Labor

- Hoisting

- Delivery Vehicle

- Production Sheets

- Unload Trucks

- Machine Operators

- Hand Trucks

- Protective Devices

- Slings

- Electrical Equipment

- Dollies

- Rig

- Assembly Line

- Storage Tanks

- Unload Materials

- Safety Procedures

- Cargo Boards

- Safety Regulations

- Sales Floor

- Safety Rules

- Booms

- Sound Effects

- Hoists

- Inventory Control

Updated January 8, 2025