Automatically apply for jobs with Zippia

Upload your resume to get started.

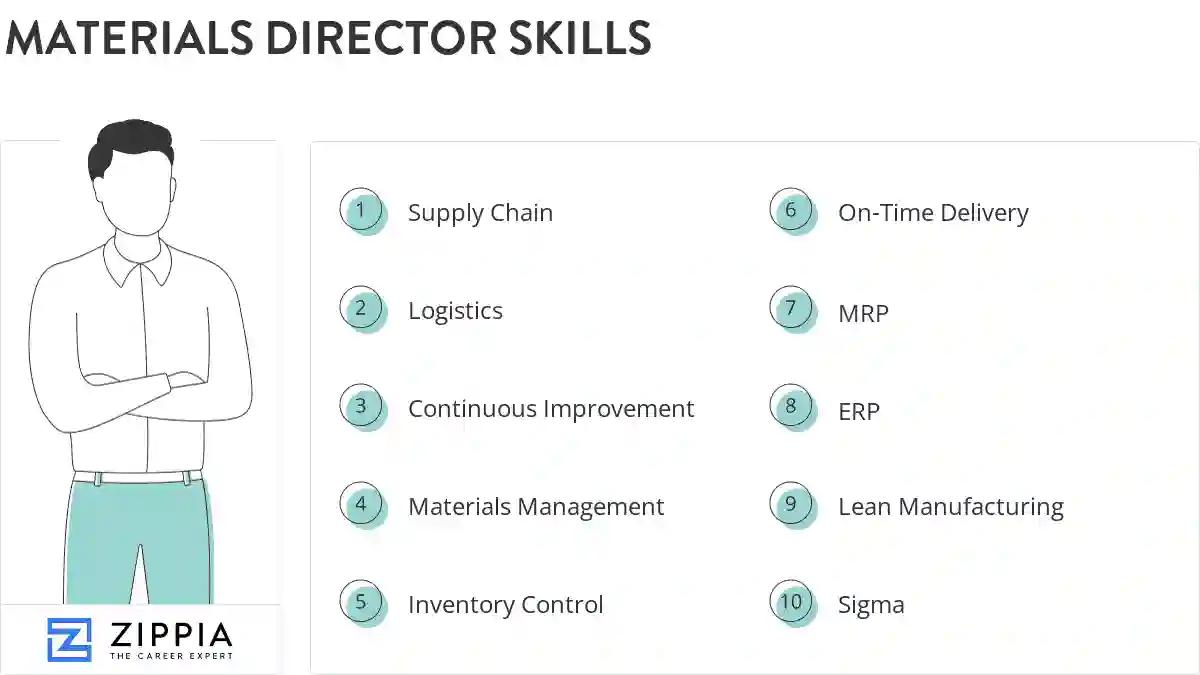

Materials director skills for your resume and career

15 materials director skills for your resume and career

1. Supply Chain

A supply chain is a network or a sequence by which finished products of a company are distributed to retailers and then supplied to the end-users. The distribution of products and services from the production line to the final buyers is carried out in a series of steps including; manufacturing, transportation, and their distribution. The whole supply chain consists of different entities including; manufacturers, transportation, warehouses, suppliers, and retailers. The entities ensure that the products retain their originality while also minimizing the cost of delivery.

- Recruited to bridge gap between Global Supply Chain and Manufacturing, allowing manufacturing sites to participate in and execute initiatives.

- Chartered with significantly simplifying the supply chain/order management process for the $10 Billion Microprocessor division.

2. Logistics

Logistics is a complete organization and implementation of a problem. Logistics are often considered in a complex business operation, as some works need detailed plannings. Logistics are also used in military action.

- Finished Goods - Catalyst for controlled warehousing standards to simplify the material handling logistics process, eliminating unneeded handling and searching.

- Formed cross-functional team at plant and developed operational restructuring action around on-site logistics that provides supply choices that avoid exploitation

3. Continuous Improvement

Continuous improvement is an ongoing process of improvement of products, services, and processes with the help of innovative ideas. It is an organized approach that helps an organization to find its weaknesses and improve them.

- Established Spare Part replenishment programs, and implemented various continuous improvement processes throughout the Materials Organization to improve overall performance.

- Created an environment that encouraged continuous improvement through lean six sigma methodologies and advanced planning techniques.

4. Materials Management

Materials management refers to the process of monitoring and controlling the inventory and use of materials, often within a manufacturing plant. This management may also require shipping and delivery of the materials depending on the material product, price, and customer demand.

- Facilitated company acquisition assimilation activities for Materials Management

- Managed the Materials Management Group to determine and set up multiple distributional locations.

5. Inventory Control

- Directed centralized procurement, production and inventory control, global sourcing and purchasing through two department managers.

- Complete responsibility for Purchasing, vendor negotiations, inventory control and customer quotes.

6. On-Time Delivery

On-Time Delivery, or OTD, is a metric that measures the rate at which finished goods and deliveries are completed on time. This rate is measured by the overall number of units shipped within a specified time frame agreed upon by the consumer and supplier. On-Time Delivery allows suppliers' compliance with delivery deadlines, and hence their consistency, to be assessed using a continuous and collaborative development approach.

- Created, implemented and managed production planning processes; improved operations utilization, operations productivity, customer service and on-time delivery.

- Developed and implemented Supplier Scorecard metrics and weekly On-Time delivery metrics.

Choose from 10+ customizable materials director resume templates

Build a professional materials director resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your materials director resume.7. MRP

MRP is an abbreviation of Material Requirements Planning and refers to the control system which is implemented in the planning and management of the activities related to manufacturing. Through MRP, manufacturers can easily schedule the production and it can also be used for inventory. MRP systems are mostly software-based but the process can also be carried out manually.

- Designed improvements to company MRP system providing Purchasing staff with improved visibility of material requirements.

- Enhanced productivity and efficiency by rolling-out numerous MRP software capabilities throughout organization.

8. ERP

Enterprise Resource Planning (ERP) is computer software used by major corporations and organizations for conducting their management and accounting tasks efficiently. ERP systems bind different business processes with each other allowing smoother flow of data between them resulting in swift project assessment and completion.

- Provided direction and testing of NetSuite ERP system implementation at 4 manufacturing facilities.

- Managed cross-functional teams during the implementation of an ERP system that was successfully installed and maintained without affecting the revenue stream.

9. Lean Manufacturing

- Lead implementation of lean manufacturing in multiple manufacturing lines to drive efficiency and significantly cut costs for 400-person manufacturing operation.

- Implemented Lean Manufacturing methodologies to drive cost savings and efficiency.

10. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Applied lean six sigma processes in of support of 2011 operational objectives resulting in improve margins and reduced manufacturing cycle times.

- Utilized Lean Six Sigma principles that improved administrative processes and reduced Purchasing headcount 25%.

11. Cost Reduction

- Coordinate cost reductions with the purchasing and engineering through negotiations and sourcing domestically and internationally.

- Direct the Purchasing organization in utilizing the reverse auction process for double-digit cost reductions.

12. Direct Reports

- Direct reports include two Purchasing/Material Analyst Managers, one Production Control Manager and one Inventory/Shipping/Receiving Manager.

- Direct reports included: Inventory Manager, Scheduling Manager, Transportation Manager, Demand Planning Manager, and 3 Project Managers.

13. Shipping Receiving

- Managed purchasing, production/inventory control, Shipping receiving and warehouse departments for two separate manufacturing locations.

- Manage materials group; shipping receiving; put away and 5S functions.

14. Production Control

Production control is the component of management that directs, plans, and controls the supply and processing of raw material. Any enterprise does this so that specific products get produced by a stipulated approach to convene an authorized sales programme. Production control is often executed from a control or operations room.

- Established global center of excellence for materials and production control management processes.

- Ensured excellence in oversight of production control and inventory management functions.

15. ISO

- Led assembly operations and materials during major line reconfiguration and ISO certification.

- Developed procedures and obtained ISO 9001 certification.

5 Materials Director resume examples

Build a professional materials director resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your materials director resume.

What skills help Materials Directors find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

What type of skills will young materials directors need?

Assistant Professor and Program Coordinator, Pennsylvania State University - New Kensington

Businesses also need to know if their new employees can effectively interact with internal or external audiences. In this regard, excellent presentation skills are the minimum expectation from businesses. Presentation skills (both formal and informal) include the ability to read people, to communicate, and to covey information appropriately to the different types of audiences they may encounter - and these may sometimes include bored, skeptical, adversarial or even hostile audiences.

Every organization also requires graduates to show that they are good team-players. In addition to that, it is a big advantage if graduates can also demonstrate sound leadership skills in the context of teamwork. This is because new employees with leadership potential are viewed as those who are willing to go the extra mile, able to function with minimum supervision, can roll with the punches to jump back into the fray, and trusted to welcome (instead of to avoid) new assignments or challenges. Leadership skills are also seen as closely aligned with the possession of a corporate entrepreneurial mindset in that such employees are more willing to challenge the status quo, come up with out-of-the-box ideas, and help lead transformation efforts that can guide the organization in the future.

List of materials director skills to add to your resume

The most important skills for a materials director resume and required skills for a materials director to have include:

- Supply Chain

- Logistics

- Continuous Improvement

- Materials Management

- Inventory Control

- On-Time Delivery

- MRP

- ERP

- Lean Manufacturing

- Sigma

- Cost Reduction

- Direct Reports

- Shipping Receiving

- Production Control

- ISO

- Material Planning

- Aerospace

- Inventory Management

- Production Planning

- Process Improvement

- Strategic Sourcing

- Purchase Orders

- Kanban

- Supplier Performance

- Chain Management

- Inventory Turns

- WIP

- Abc Analysis

- Electronic Components

- Master Scheduling

- Material Costs

- Chain Processes

- OTD

- MRO

- KPI

- Materials Organization

- Global Sourcing

- Production Scheduling

- Inventory Accuracy

- Supplier Quality

- Distribution Centers

- VMI

- JIT

- Supply Chain Planning

- Material Flow

- Product Development

- Goods Inventory

- EDI

Updated January 8, 2025