What does a mechanical spreader operator do?

A mechanical spreader operators manage and operate all equipment in various industries where they perform their jobs. The operators work as general mechanics in building HVAC, general building maintenance, and pump station operations. They test electro-mechanical subsystems for operational reliability and circuit integrity. Their job includes promoting quality assurance and performance improvement programs within the organization. Also, they perform an energy audit to improve the efficiency of HVAC energy.

Mechanical spreader operator responsibilities

Here are examples of responsibilities from real mechanical spreader operator resumes:

- Accomplish in arc, gas, MIG, and TIG welding.

- Manage an internal environmental information system and ensure compliance with EPA and RCRA regulations.

- Skil in MIG and TIG.

- Experience with fiber optics, time & PLC programming.

- Follow GMP rules and current compliance regulations and standards.

- Assemble all gardening tools, lawnmowers, rakes etc.

- Insure PLC systems are working normal and fix as needed.

- Perform various building maintenance duties such as light plumbing, carpentry, and basic electrical and mechanical.

- Perform as a general mechanic relating to building HVAC, pump station operations and general building maintenance.

- Trouble shooting machines such as shakers, rollers, elevators, conveyors, hull grinders, and blowers.

- Maintain and safely operate various equipment, including a spreader truck, backpack sprayers, rotary and drop spreaders.

- Champion new PPE requirements for better ergonomic performance.

- Conduct energy audit of an existing facility to improve HVAC energy efficiency.

- Ensure the timely departure of locomotives that require preventive maintenance and/or repairs.

- Repair plumbing relate items operate equipment for demolition and sewer and water repairs and installs

Mechanical spreader operator skills and personality traits

We calculated that 10% of Mechanical Spreader Operators are proficient in Hand Tools, Plumbing, and Preventive Maintenance. They’re also known for soft skills such as Analytical skills, Detail oriented, and Math skills.

We break down the percentage of Mechanical Spreader Operators that have these skills listed on their resume here:

- Hand Tools, 10%

Fit and assist in fitting valves, couplings, or assemblies to tanks, pumps, or systems using hand tools.

- Plumbing, 6%

Repair plumbing related items operate equipment for demolition and sewer and water repairs and installs

- Preventive Maintenance, 6%

Trained equipment operators in preventive maintenance procedures and safe operation of MST Equipment.

- Safety Procedures, 5%

Implemented improved maintenance and safety procedures with greater efficiency and productivity ratios on evening shift.

- Repair Equipment, 5%

Transport equipment between job sites and repair equipment and vehicles in the shop in the off season.

- Mechanical Systems, 4%

Utilized blueprints/system schematics and technical research to troubleshoot repair maintenance on mechanical systems.

"hand tools," "plumbing," and "preventive maintenance" are among the most common skills that mechanical spreader operators use at work. You can find even more mechanical spreader operator responsibilities below, including:

Analytical skills. To carry out their duties, the most important skill for a mechanical spreader operator to have is analytical skills. Their role and responsibilities require that "water and wastewater treatment plant and system operators must conduct tests and inspections on water or wastewater and evaluate the results." Mechanical spreader operators often use analytical skills in their day-to-day job, as shown by this real resume: "aided mechanical department in the design and planning of data centers, including three-dimensional drafting in autocad mep 2008. "

Detail oriented. Another essential skill to perform mechanical spreader operator duties is detail oriented. Mechanical spreader operators responsibilities require that "water and wastewater treatment plant and system operators must monitor machinery, gauges, dials, and controls to ensure everything is operating properly." Mechanical spreader operators also use detail oriented in their role according to a real resume snippet: "can run crews and am detailed in preventive maintenance. "

Math skills. Another skill that relates to the job responsibilities of mechanical spreader operators is math skills. This skill is critical to many everyday mechanical spreader operator duties, as "water and wastewater treatment plant and system operators must have the ability to apply data to formulas that determine treatment requirements, flow levels, and concentration levels." This example from a resume shows how this skill is used: "compiled energy usage and environmental statistics for electrical and hvac departments. "

Mechanical skills. mechanical spreader operator responsibilities often require "mechanical skills." The duties that rely on this skill are shown by the fact that "water and wastewater treatment plant and system operators must know how to work with machines and use tools." This resume example shows what mechanical spreader operators do with mechanical skills on a typical day: "provide preventive maintenance and daily repair of mechanical components in the manufacturing line process. "

The three companies that hire the most mechanical spreader operators are:

- Boeing2 mechanical spreader operators jobs

- Bristol-Myers Squibb1 mechanical spreader operators jobs

- Con Edison1 mechanical spreader operators jobs

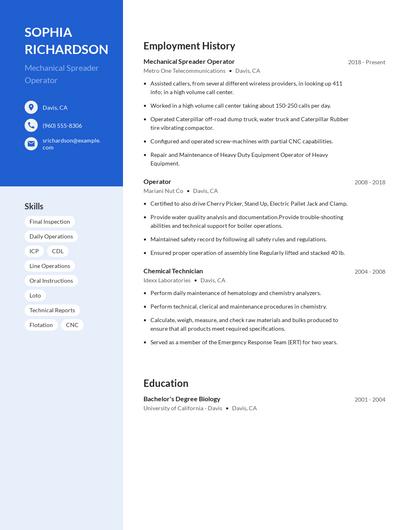

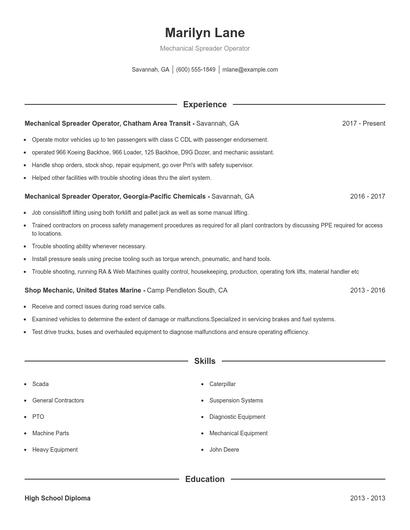

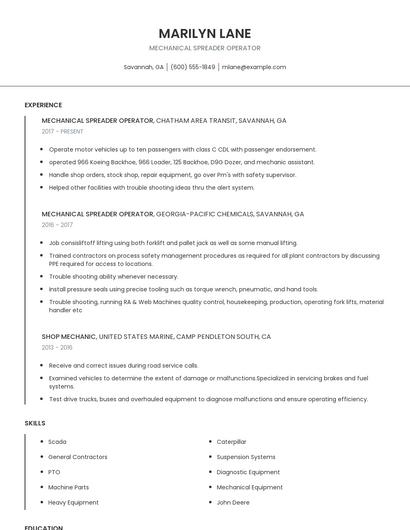

Choose from 10+ customizable mechanical spreader operator resume templates

Build a professional mechanical spreader operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your mechanical spreader operator resume.Compare different mechanical spreader operators

Mechanical spreader operator vs. Forklift driver

A forklift operator is responsible for managing and operating industrial trucks and machines to ensure its performance safety and stability. Forklift operators' duties include safely handling of deliveries, securely moving items to storage areas, monitoring inventories and supplies, running diagnostic tests, reporting inspected malfunctions and deficiencies, performing basic troubleshooting, and adhering to safety procedures. It is a requirement that a forklift operator must have excellent time-management skills, as well as the ability to multi-task for daily operations.

There are some key differences in the responsibilities of each position. For example, mechanical spreader operator responsibilities require skills like "hand tools," "plumbing," "repair equipment," and "mechanical systems." Meanwhile a typical forklift driver has skills in areas such as "pallets," "electric pallet jack," "load trucks," and "stand-up forklift." This difference in skills reveals the differences in what each career does.

Forklift drivers earn the highest salaries when working in the manufacturing industry, with an average yearly salary of $38,078. On the other hand, mechanical spreader operators are paid more in the energy industry with an average salary of $48,520.forklift drivers tend to reach similar levels of education than mechanical spreader operators. In fact, forklift drivers are 1.5% less likely to graduate with a Master's Degree and 0.1% less likely to have a Doctoral Degree.Mechanical spreader operator vs. Driver/warehouse worker

A driver/warehouse worker is responsible for transporting goods and services from the warehouse or distribution center to specific destinations based on the delivery details. Driver/warehouse workers assist in loading and unloading items from delivery trucks, storing merchandise to the appropriate warehouse areas, operating various warehouse tools and equipment, and inspecting the delivery vehicle for any engine defects that might cause delays. They also check the inventory report to ensure the correct quantity of items and escalate customers' complaints to the warehouse management for immediate resolution, such as product replacement or issuing refunds.

Each career also uses different skills, according to real mechanical spreader operator resumes. While mechanical spreader operator responsibilities can utilize skills like "hand tools," "plumbing," "preventive maintenance," and "safety procedures," driver/warehouse workers use skills like "customer service," "delivery truck," "load trucks," and "electric pallet jack."

Driver/warehouse workers earn a lower average salary than mechanical spreader operators. But driver/warehouse workers earn the highest pay in the manufacturing industry, with an average salary of $35,536. Additionally, mechanical spreader operators earn the highest salaries in the energy with average pay of $48,520 annually.driver/warehouse workers earn similar levels of education than mechanical spreader operators in general. They're 1.2% less likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.Mechanical spreader operator vs. Lift driver

A lift driver is responsible for operating warehouse machines and vehicles, especially on loading and unloading items from distribution trucks and transporting the merchandise to different parts of the warehouse. Lift drivers inspect the efficiency and reliability of the machines, ensuring its operational and optimal performance to avoid production delays. They also verify the number of products for distribution according to the order requests and shipment details. A lift driver must be highly-organized, as well as having excellent time-management skills to perform duties and meet strict production schedules.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a mechanical spreader operator is likely to be skilled in "hand tools," "plumbing," "preventive maintenance," and "safety procedures," while a typical lift driver is skilled in "fork-lift," "pallets," "safety standards," and "load trucks."

Lift drivers make a very good living in the automotive industry with an average annual salary of $38,145. On the other hand, mechanical spreader operators are paid the highest salary in the energy industry, with average annual pay of $48,520.lift drivers typically earn similar educational levels compared to mechanical spreader operators. Specifically, they're 1.3% less likely to graduate with a Master's Degree, and 0.1% less likely to earn a Doctoral Degree.Mechanical spreader operator vs. Forklift operator and receiver

Types of mechanical spreader operator

Updated January 8, 2025