What does a numerical control operator do?

A numerical control operator is responsible for monitoring machinery and managing computer-generated equipment to produce tools and components from various mechanical resources. Numerical control operators must have extensive knowledge with the technology and mechanical industry to perform basic troubleshooting and detect malfunctions during operations. A numerical control operator duties' also include inspecting equipment setup and finished products, ensuring high-quality parts, reviewing blueprints, following client's specifications for making adjustments, and adhering to the safety guidelines and procedures required by the business.

Numerical control operator responsibilities

Here are examples of responsibilities from real numerical control operator resumes:

- Perform trial runs on new CNC programs, working with programming and tooling to achieve satisfactory parts.

- Set up and run vertical milling machines and Mori-Seiki lathes

- Calculate dimensions and tolerances using knowledge of mathematics and instruments such as micrometers and calipers

- Set up and operate machine turning tools (lathes, MAZAK).

- Used manual and CNC mills (HAAS), lathes (HAAS) and (OKUMA) and surface grinders.

- Mill and lathe g-code programming.

- Set up and operate co2 and fiber lasers.

- Set mill gauges to specify fineness of gring.

- Make sure the CO2 laser beam is in alignment.

- Operate auto-milling machine (MAZAK) producing brass refrigerant valves.

- Follow GMP and OSHAA guidelines as company are VPP certify.

- Change inserts in a HAAS CNC lathe quickly and as needed.

- Operate Trumpf laser to production standards to consistently produce quality parts.

- Help out the brake press operators and run Amada punch press.

- Operate a CNC YAG laser to drill new cooling holes on turbine blades.

Numerical control operator skills and personality traits

We calculated that 12% of Numerical Control Operators are proficient in Calipers, Micrometers, and Math. They’re also known for soft skills such as Computer skills, Dexterity, and Physical strength.

We break down the percentage of Numerical Control Operators that have these skills listed on their resume here:

- Calipers, 12%

Guaranteed smooth procedures by utilizing specified gauges and calipers.

- Micrometers, 9%

Calibrated or adjusted equipment to ensure quality production using mechanic tools and measuring devices such as micrometers.

- Math, 6%

Ensured machinery parts met specification requirements using machine shop math.

- Lathe Machines, 6%

Operated computer numerical controlled lathe machine.

- Hand Tools, 6%

Perform inspections and machined parts using hand tools and precision measurement equipment including computerized measurement machines.

- Safety Standards, 4%

Maintained comprehensive safety standards on all job sites, immediately reporting and correcting violations.

Common skills that a numerical control operator uses to do their job include "calipers," "micrometers," and "math." You can find details on the most important numerical control operator responsibilities below.

Computer skills. The most essential soft skill for a numerical control operator to carry out their responsibilities is computer skills. This skill is important for the role because "metal and plastic machine workers often must be able to use programmable devices, computers, and robots on the factory floor." Additionally, a numerical control operator resume shows how their duties depend on computer skills: "operated a computer aided design table. "

Dexterity. Another essential skill to perform numerical control operator duties is dexterity. Numerical control operators responsibilities require that "metal and plastic machine workers who work in metal and plastic machined goods manufacturing use precise hand movements to make the necessary shapes, cuts, and edges that designs require." Numerical control operators also use dexterity in their role according to a real resume snippet: "have ability to safely operate overhead cranes and posses a thorough knowledge of lifting devices as well as safe rigging practices. "

Physical strength. This is an important skill for numerical control operators to perform their duties. For an example of how numerical control operator responsibilities depend on this skill, consider that "metal and plastic machine workers must be strong enough to guide and load heavy and bulky parts and materials into machines." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a numerical control operator: "fulfilled production responsibilities to customer while maintaining superior quality using physical gauges and cmm machines. ".

Mechanical skills. A big part of what numerical control operators do relies on "mechanical skills." You can see how essential it is to numerical control operator responsibilities because "metal and plastic machine workers set up and operate machinery." Here's an example of how this skill is used from a resume that represents typical numerical control operator tasks: "performed cmm mechanical quality inspection using mitutoyo cmm (mcosmos-m1). "

The three companies that hire the most numerical control operators are:

- CEM

453 numerical control operators jobs

- Nexus Staffing Solutions141 numerical control operators jobs

- TPI127 numerical control operators jobs

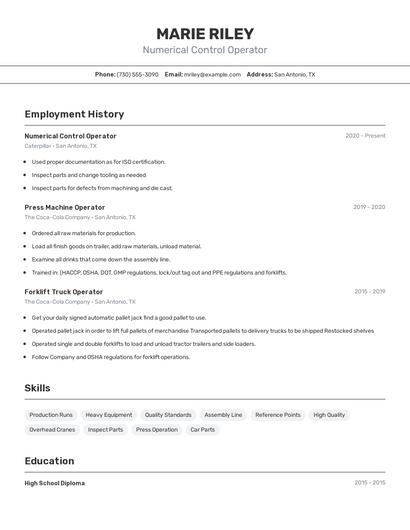

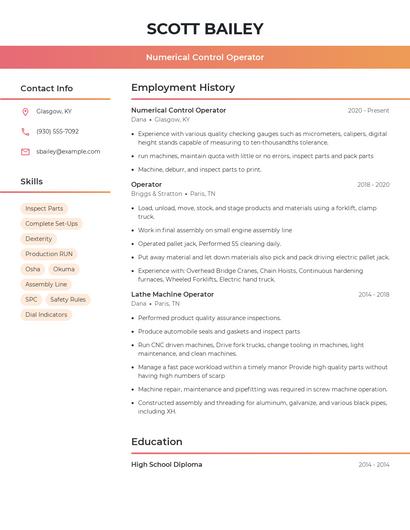

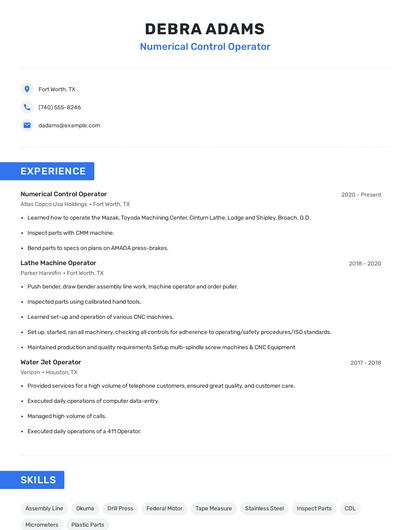

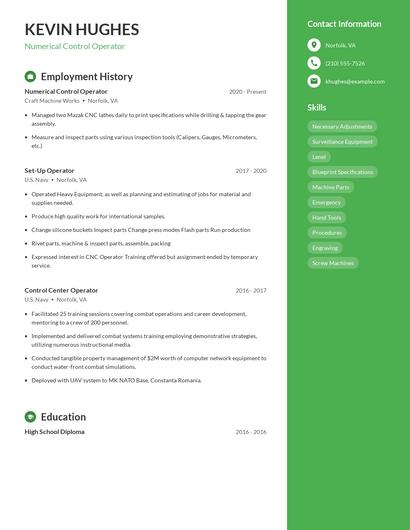

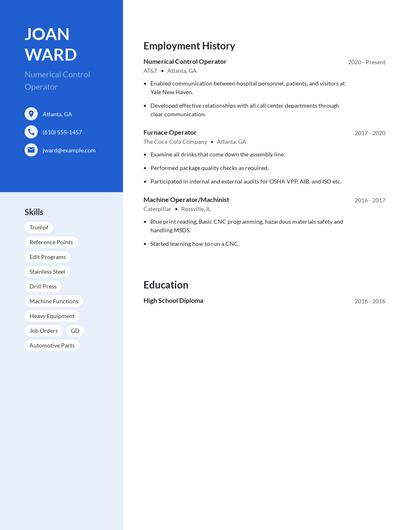

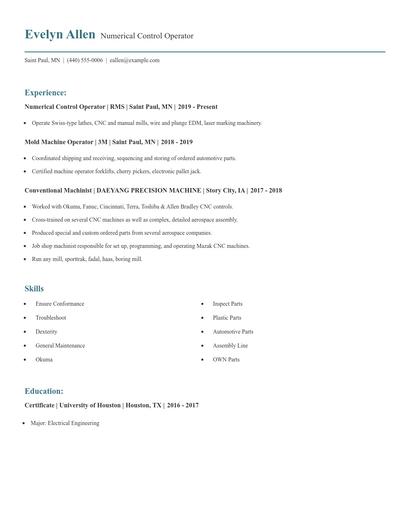

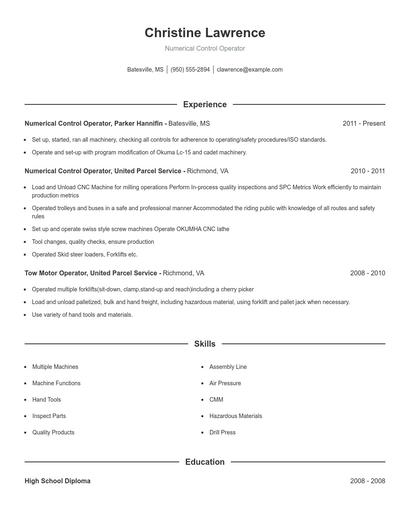

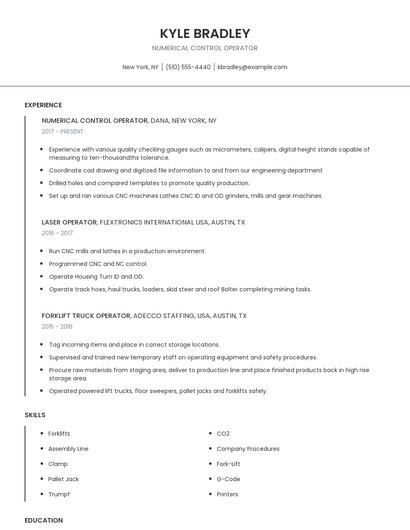

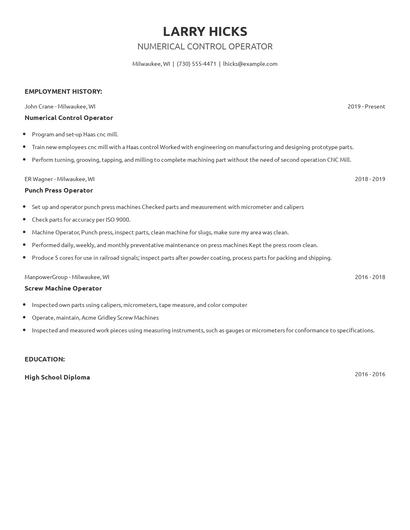

Choose from 10+ customizable numerical control operator resume templates

Build a professional numerical control operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your numerical control operator resume.Compare different numerical control operators

Numerical control operator vs. Machinist

Machinists are skilled professionals who create metal works by using different machines. They work with clients to bring their clients' vision to life. They study the blueprints of the product that needs to be done and identify the parts that will need fabrication through machining. They then prepare the materials and equipment. Machinists use different tools such as grinders, drills, lathes, polishers, and milling equipment to create parts that are made of metal. They may sometimes work with other materials such as wood or plastic, but this is seldom. Machinists are expected to be proficient in the use of the machines, to be precise with their work, and can work within the committed timeline.

While similarities exist, there are also some differences between numerical control operators and machinist. For instance, numerical control operator responsibilities require skills such as "lathe machines," "safety standards," "basic math," and "quality standards." Whereas a machinist is skilled in "grinders," "cnc machines," "machine shop," and "cnc lathes." This is part of what separates the two careers.

Machinists really shine in the automotive industry with an average salary of $53,086. Comparatively, numerical control operators tend to make the most money in the automotive industry with an average salary of $41,888.The education levels that machinists earn slightly differ from numerical control operators. In particular, machinists are 0.1% more likely to graduate with a Master's Degree than a numerical control operator. Additionally, they're 0.0% more likely to earn a Doctoral Degree.Numerical control operator vs. Maintenance machinist

A Maintenance Machinist is responsible for implementing and maintaining industrial machinery. Their primary duties include investigating and diagnosing equipment failures and performing corrective actions.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that numerical control operator responsibilities requires skills like "micrometers," "lathe machines," "safety standards," and "basic math." But a maintenance machinist might use other skills in their typical duties, such as, "cnc," "grinders," "osha," and "cranes."

Maintenance machinists earn a higher average salary than numerical control operators. But maintenance machinists earn the highest pay in the technology industry, with an average salary of $61,086. Additionally, numerical control operators earn the highest salaries in the automotive with average pay of $41,888 annually.In general, maintenance machinists achieve similar levels of education than numerical control operators. They're 0.2% more likely to obtain a Master's Degree while being 0.0% less likely to earn a Doctoral Degree.Numerical control operator vs. Machine operator/machinist

Operators are skilled workers who are in charge of working on an industrial machine or a specific aspect of the manufacturing business. They are trained to operate machines, learning how to use them. They are also responsible for the maintenance and repair of the machine, and they should be able to troubleshoot problems and provide remedies to them. They must be knowledgeable about the different parts of the machine and how to mitigate any challenges that may arise. Operators should be alert, detail-oriented, and familiar with safety and health guidelines.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a numerical control operator is likely to be skilled in "hand tools," "safety standards," "basic math," and "preventative maintenance," while a typical machine operator/machinist is skilled in "cnc lathes," "grinders," "cnc machines," and "machine shop."

Most machine operators/machinist achieve a similar degree level compared to numerical control operators. For example, they're 0.7% more likely to graduate with a Master's Degree, and 0.1% more likely to earn a Doctoral Degree.Numerical control operator vs. Operator

Types of numerical control operator

Updated January 8, 2025