What does a packaging supervisor do?

A packaging supervisor ensures all packaging procedures are done safely, and on time. This person's responsibility is to make sure that the packaging process is without problems, from the warehouse to the intended destination. This person also monitors all stored items, how they are packaged, what materials are used for packaging, and offers solutions for issues that may appear during the production process. A packaging supervisor is necessary for companies that require a lot of packaging goods and the moving business, where furniture and other items of value are often packaged carefully to avoid damages during transport.

Packaging supervisor responsibilities

Here are examples of responsibilities from real packaging supervisor resumes:

- Manage capital equipment expenditures, tooling and fixturing costs, and CNC programs.

- Manage a team of 16-35 to insure packaging lines are running to standards as far as USDA guidelines and company productivity.

- Provide direction to production workers relating to GMP's, food safety, sanitation and regulatory requirements

- Monitor daily to ensure HACCP and USDA standards are being meet.

- Enforce compliance with all company policies and procedures, as well as OSHA requirements.

- Work with QA, planning and warehouse distribution to resolve and meet production issues.

- Monitor employee safety behavior with EHS department for the purpose of safety compliance guidelines.

- Originate unique safety and awareness meetings to train and inform employees on OSHA safety matters.

- Coordinate daily production schedule, training of new employees and reconciling of batch records in accordance with FDA guidelines.

- Conduct GMP inspections of manufacturing areas.

- Monitor control plans, troubleshoot workmanship problems and supervise production activities to ensure manufacture products meet or exceed establish quality requirements.

- Use KPI's to improve labor efficiencies.

- Implement performance management, production goals, and KPI's.

- Utilize TPS techniques to standardize process/methods, identify waste, methodically eliminate waste and standardize the new process/ methods.

Packaging supervisor skills and personality traits

We calculated that 8% of Packaging Supervisors are proficient in Safety Procedures, GMP, and Quality Standards. They’re also known for soft skills such as Interpersonal skills, Leadership skills, and Problem-solving skills.

We break down the percentage of Packaging Supervisors that have these skills listed on their resume here:

- Safety Procedures, 8%

Consulted daily with Maintenance and Quality Control departments to ensure proper procedures are used in relation to Safety procedures and paperwork.

- GMP, 8%

Performed Batch Record and Logbook reviews to ensure proper process execution and GMP requirements before delivery to the Quality Assurance Department.

- Quality Standards, 7%

Executed production order to meet required quantity, production efficiency, completion date and quality standards.

- Direct Supervision, 6%

Direct supervision of 20 unionized warehouse operators 20 Packaging operators.

- FDA, 5%

Selected as manufacturing representative for all FDA audits and Customer Inspections.

- Process Improvement, 4%

Implemented equipment preventive maintenance programs, purchased spare parts, controlled operating budgets and reported on day-to-day expenses and process improvements.

Most packaging supervisors use their skills in "safety procedures," "gmp," and "quality standards" to do their jobs. You can find more detail on essential packaging supervisor responsibilities here:

Interpersonal skills. One of the key soft skills for a packaging supervisor to have is interpersonal skills. You can see how this relates to what packaging supervisors do because "industrial production managers must have excellent communication skills to work well other managers and with staff." Additionally, a packaging supervisor resume shows how packaging supervisors use interpersonal skills: "exercised excellent interpersonal skills to collaborate with internal teams to identify and correct quality issues. "

Leadership skills. Many packaging supervisor duties rely on leadership skills. "to keep the production process running smoothly, industrial production managers must motivate and direct employees.," so a packaging supervisor will need this skill often in their role. This resume example is just one of many ways packaging supervisor responsibilities rely on leadership skills: "enforced a culture of lean manufacturing and continuous improvement while providing operational leadership. "

Problem-solving skills. packaging supervisors are also known for problem-solving skills, which are critical to their duties. You can see how this skill relates to packaging supervisor responsibilities, because "production managers must identify and address problems that arise." A packaging supervisor resume example shows how problem-solving skills is used in the workplace: "investigated issues, identified solutions, and recommended types ofknowledge of fda action. "

The three companies that hire the most packaging supervisors are:

- Hormel Foods8 packaging supervisors jobs

- Thermo Fisher Scientific5 packaging supervisors jobs

- ASR Group4 packaging supervisors jobs

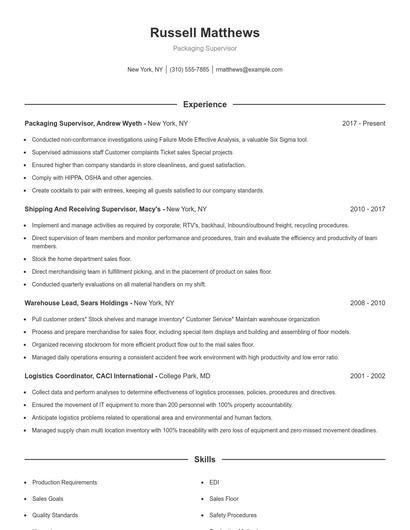

Choose from 10+ customizable packaging supervisor resume templates

Build a professional packaging supervisor resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your packaging supervisor resume.Compare different packaging supervisors

Packaging supervisor vs. Quality assurance supervisor

A quality assurance supervisor oversees and leads the quality control operations within a manufacturing plant or similar establishment. They are primarily responsible for crafting and implementing policies that prioritize the efficiency of products or services, supervising and evaluating the performances of the workforce, and setting standards and procedures that align not just with the goals of the company, but the national and international level of production standards. Furthermore, as a supervisor in the field, it is crucial to encourage and shape quality assurance workers into valuable members of the company.

These skill sets are where the common ground ends though. The responsibilities of a packaging supervisor are more likely to require skills like "safety procedures," "direct supervision," "production schedules," and "osha." On the other hand, a job as a quality assurance supervisor requires skills like "product quality," "customer service," "iso," and "patients." As you can see, what employees do in each career varies considerably.

Quality assurance supervisors earn the highest salaries when working in the health care industry, with an average yearly salary of $80,377. On the other hand, packaging supervisors are paid more in the pharmaceutical industry with an average salary of $63,748.On average, quality assurance supervisors reach similar levels of education than packaging supervisors. Quality assurance supervisors are 2.7% more likely to earn a Master's Degree and 0.0% more likely to graduate with a Doctoral Degree.Packaging supervisor vs. Assembly supervisor

Assembly Supervisors oversee and coordinate employees' work on assembly-lines. The supervisors assign personnel to stations or tasks and prepare their work schedules. They monitor processes to make sure that the employees are carrying out their tasks correctly. It is their responsibility to monitor the whole assembly process for delay prevention. They also contribute to developing procedures and processes to boost the overall operation of the assembly lines.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that packaging supervisor responsibilities requires skills like "gmp," "direct supervision," "fda," and "osha." But an assembly supervisor might use other skills in their typical duties, such as, "assembly line," "assembly operations," "delivery dates," and "assembly procedures."

On average, assembly supervisors earn a higher salary than packaging supervisors. Some industries support higher salaries in each profession. Interestingly enough, assembly supervisors earn the most pay in the automotive industry with an average salary of $79,821. Whereas packaging supervisors have higher pay in the pharmaceutical industry, with an average salary of $63,748.In general, assembly supervisors achieve similar levels of education than packaging supervisors. They're 2.0% less likely to obtain a Master's Degree while being 0.0% less likely to earn a Doctoral Degree.Packaging supervisor vs. 3rd shift supervisor

A 3rd shift supervisor is responsible for monitoring the operations and staff performance of a specific shift. 3rd shift supervisors strategize on effective business techniques to maximize staff's productivity and improve customers' experience. They also analyze sales reports, resolve discrepancies, and identify business opportunities that would generate more resources for revenues and increase the company's profitability. A 3rd shift supervisor addresses customers' inquiries and concerns, as well as resolving their complaints about services timely and accurately.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a packaging supervisor is likely to be skilled in "direct supervision," "corrective action," "equipment performance," and "food safety," while a typical 3rd shift supervisor is skilled in "customer service," "basic math," "pallet jack," and "cleanliness."

3rd shift supervisors earn the highest salary when working in the transportation industry, where they receive an average salary of $35,104. Comparatively, packaging supervisors have the highest earning potential in the pharmaceutical industry, with an average salary of $63,748.When it comes to education, 3rd shift supervisors tend to earn similar degree levels compared to packaging supervisors. In fact, they're 2.9% less likely to earn a Master's Degree, and 0.3% less likely to graduate with a Doctoral Degree.Packaging supervisor vs. Production supervisor/manager

Production supervision managers display strong skills in supervision, decision-making, effective planning, and also have a keen eye for detail. This career will call on the maintenance of a production line's operations, as well as the ongoing production of the end product, in addition to maximizing production while maintaining quality products and staff safety.

Types of packaging supervisor

Updated January 8, 2025