Automatically apply for jobs with Zippia

Upload your resume to get started.

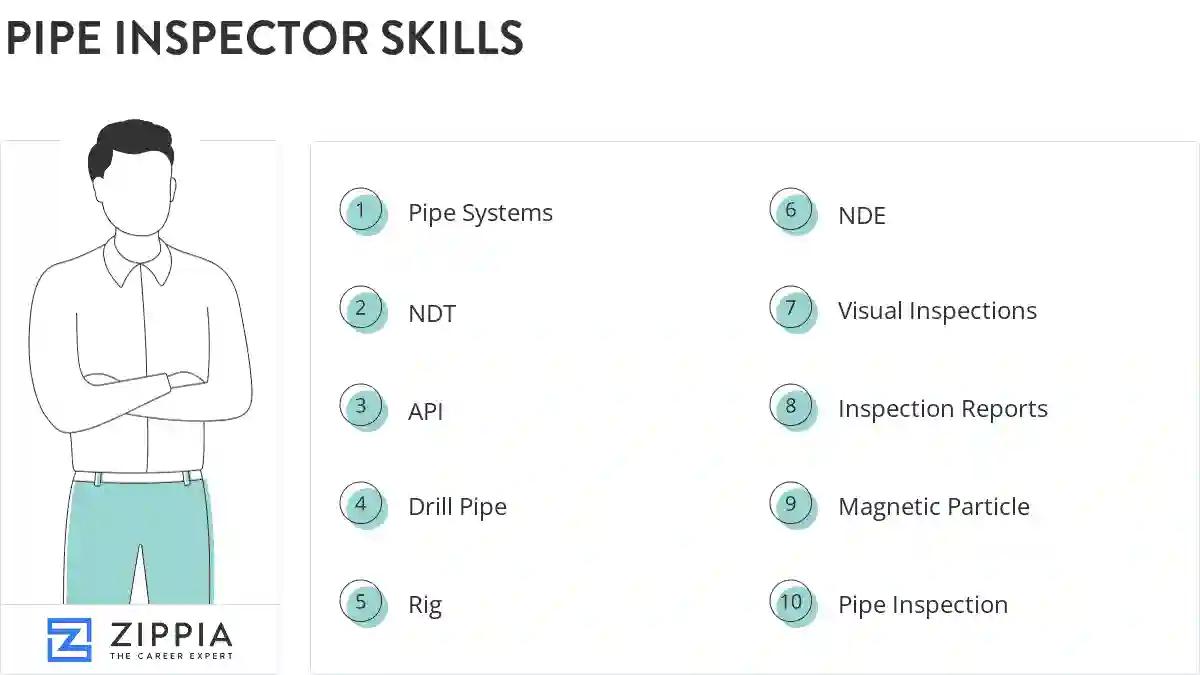

Pipe inspector skills for your resume and career

15 pipe inspector skills for your resume and career

1. Pipe Systems

Pipe systems are the interconnection of pipes and plumbing that allow the various taps in a home or structure to produce water.

- Reviewed hydro's travelers and walked down pipe systems to verify all specifications has been met.

- Installed pipe systems and plumbing.

2. NDT

Non-Destructive Testing, NDT, is a combination of different test techniques used individually or collectively to evaluate the integrity and properties of a material, component, system, or structure without permanently altering it. NDT is important for safe operation, as well as for quality control and lifetime evaluation of the system. It is used in industries such as aerospace, oil, and gas, nuclear, power generation, medical, rail, general manufacturing, etc.

- Job planning, including Advanced NDT, scaffolding, mobile equipment, and insulation removal.

- Performed pipe inspection, NDT Testing and project reports.

3. API

- Determined appropriate repair/rework necessary for defects per API 5L and company Process Chart specifications.

- Provide management with update on personnel qualification pertaining to API.

4. Drill Pipe

- Inspect steel tubing pipes, casing, drill pipe caps on, and other tubular oil well equipment for defects.

- Buffed and retrieved serial numbers on drill pipes in order to log those that were damaged and or refurbished.

5. Rig

Rigging includes designing, preparing, or setting up equipment for drilling operations. This skill is one of the main and most important activities in the oil and gas industry, whether it's for onboard operations or port operations. Rigging systems should have parts like master links, shackles, slings, and lifting bags for underwater lifting. Professionals working with rigging systems are responsible for tasks like operating platform lifts, forklifts, and overhead cranes.

- Rig down and drive back to shop where the pod is washed and cleaned to get ready for next job.

- Inspect rig tools bells, elevators, Derek pretty much everything.

6. NDE

Nondestructive evaluation (NDE) is a term used in describing quantitative measurements and locating a defect. It helps identify material properties like formability and fracture toughness. Majority of people know the technology used in NDE from the medical industries such as x-ray and ultrasound.

- Determined thickness measurement locations, evaluated NDE data to determine repairs to be made, writing history briefs and repair reports.

- Observed in-process and completed welds, and coordinated NDE on a Crude/Vac turnaround project for BP-Husky Refining

Choose from 10+ customizable pipe inspector resume templates

Build a professional pipe inspector resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your pipe inspector resume.7. Visual Inspections

Visual inspection is a method used to perform quality control checks on different objects and structures. It includes techniques like data acquisition and data analysis. Moreover, a visual technique is done through quality control instruments and also human senses.

- Performed external and internal visual inspections concerning on-stream piping.

- Perform visual inspections, witness pneumatic testing and perform system walk downs prior to testing.

8. Inspection Reports

An inspection report is a written document provided after a thorough evaluation of a specific procedure/ process.

- Authored extensive written reports and inspection reports.

- Prepared daily inspection reports and reported all non-conforming issues to the Chief Inspector.

9. Magnetic Particle

Magnetic Particle testing, also known as Magnetic Particle Inspection, is a method or examination used to determine the flaws of the surface and subsurface materials like nickel, iron, cobalt, and alloy.

- Used wet/dry magnetic particle inspection to search for hairline fractures in piping.

- Maintain ultrasound and magnetic particle machine in good working order.

10. Pipe Inspection

- Received a certificate of completion on radiation safety for pipe inspection operator.

- Executed the day to day task of the process required for efficient and accurate pipe inspection.

11. EMI

- Run EMI unit Buff and powder connections Take the ultrasonic thickness of pipes Visual pipe Take full dimensions measurements of connections

- Inspected installation of electrical magnetic interference cable (EMI), welds and electrical testing of cables to strict specifications.

12. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Ensured piping systems ran efficiently without defects; performed visual and electronic inspections.

- Reason for leaving: Job ran out when oil prices dropped.

13. Destructive Testing

- Perform and document destructive testing of test coupons for various procedures and qualification of certification of procedures and welder certification.

- Completed all necessary education and testing requirements to become SNT-TC-1A practice certified in 4 nondestructive testing methods.

14. Inspection Process

The inspection processes are planning, review meeting, preparation, inspection meeting, reworking, and follow-up to meet customer requirements, wants, and needs. The objective is to prevent the defective product from flowing through subsequent operations and to avoid losses for the company.

- Help the pipe inspector with the inspection process.

- Evaluated and analyzed Inspection processes and developed and facilitated new inspection and compliance methodologies to streamline the inspection and managements programs.

15. Ultrasonic Testing

- Performed ultrasonic testing on choke manifolds, mud lines, and miscellaneous hardline components.

- Identify defects in solid materials using ultrasonic testing techniques.

5 Pipe Inspector resume examples

Build a professional pipe inspector resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your pipe inspector resume.

What skills help Pipe Inspectors find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of pipe inspector skills to add to your resume

The most important skills for a pipe inspector resume and required skills for a pipe inspector to have include:

- Pipe Systems

- NDT

- API

- Drill Pipe

- Rig

- NDE

- Visual Inspections

- Inspection Reports

- Magnetic Particle

- Pipe Inspection

- EMI

- RAN

- Destructive Testing

- Inspection Process

- Ultrasonic Testing

- Pipe Threads

- Carbon Steel

- RT

- JSA

- Test Data

- Measure Materials

- Pressure Vessels

- ISO

- Hydrostatic Testing

- MPI

- Pressure Test

- Hoists

- Meeting Specifications

- CAD

- Control Panels

- Production Problems

- NOV

- Optical Inspection Equipment

- PMI

- Safety Guidelines

- WPS

Updated January 8, 2025