What does a printer operator do?

A printer operator is tasked to operate, maintain, and troubleshoot all printing equipment in a company. This person performs all necessary printing requests coming from customers and the company and is expected to have a working knowledge of various printing equipment and printing techniques to assure quality. The printer operator must also know about design, use of color, and other creative aspects to provide last-minute adjustments on printing jobs to avoid later revisions. The printer operator is vital personnel in businesses like publishing companies and creative houses.

Printer operator responsibilities

Here are examples of responsibilities from real printer operator resumes:

- Manage day-to-day operations and supervise employees to ensure the studio run smoothly.

- Operate UV and solvent printers.

- Collate and bind print materials.

- Record HD masters, clones.

- Print operator using high speed OCE printers.

- Handle rush orders and short delivery windows.

- Complete Oc 2140/NDX operator field service training.

- Operate xerox docutech and cannon image runner.

- Well verse in Aspera and other FTP/SCP clients.

- Prepare documents and letters for distribution or USPS mail delivery.

- Encode HD and SD commercials for air on various cable networks.

- Cross-Train between wide format printers, UV flatb printer, and copiers.

- Weigh mail and packages via USPS or FedEx to determine correct postage.

- Operate xerox machines and repair binding of books, and quality control.

- Report inconsistencies and bugs in QA tools and report findings to supervisors.

Printer operator skills and personality traits

We calculated that 14% of Printer Operators are proficient in Troubleshoot, Quality Checks, and Quality Standards.

We break down the percentage of Printer Operators that have these skills listed on their resume here:

- Troubleshoot, 14%

Maintain, and troubleshoot printer malfunctions.

- Quality Checks, 9%

Perform equipment quality checks and project mergers to improve production efficiency and increase maximum production rate.

- Quality Standards, 9%

Followed procedures in a fast paced environment while maintaining quality standards.

- Basic Math, 8%

Use basic math and beable to measure.

- Windows, 5%

Operated a variety of computers and printers and extensively utilized Windows 2000, Word, Excel, PowerPoint and Access.

- Preventive Maintenance, 5%

Conducted operator level preventive maintenance on all assigned equipment according to the preventive maintenance schedule.

Common skills that a printer operator uses to do their job include "troubleshoot," "quality checks," and "quality standards." You can find details on the most important printer operator responsibilities below.

The three companies that hire the most printer operators are:

- Quad123 printer operators jobs

- Conduent112 printer operators jobs

- Creative Converting

35 printer operators jobs

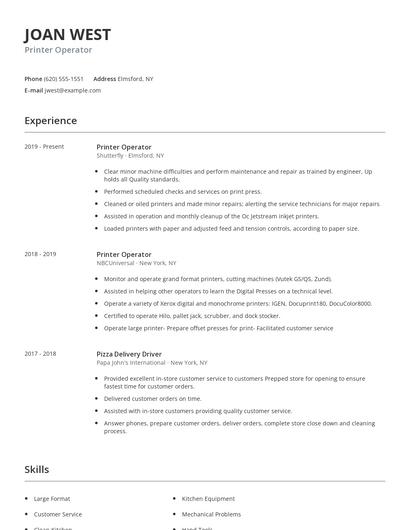

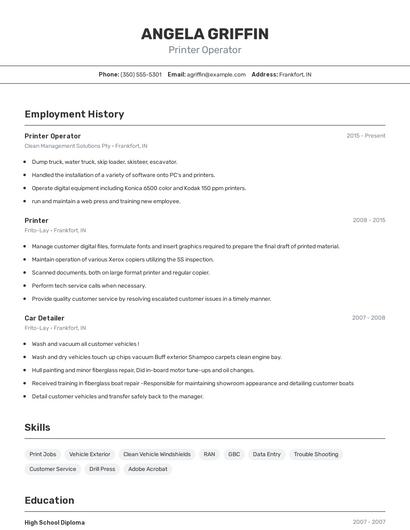

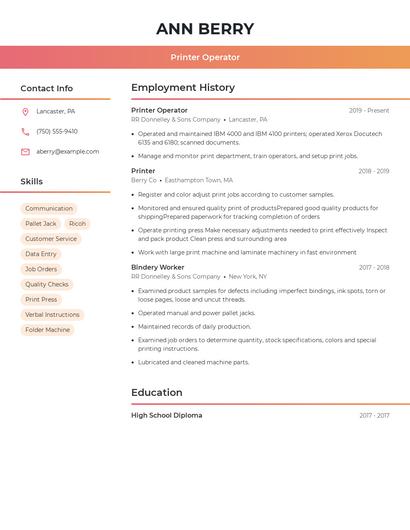

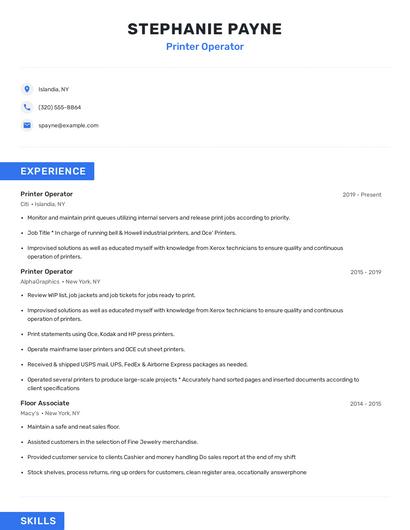

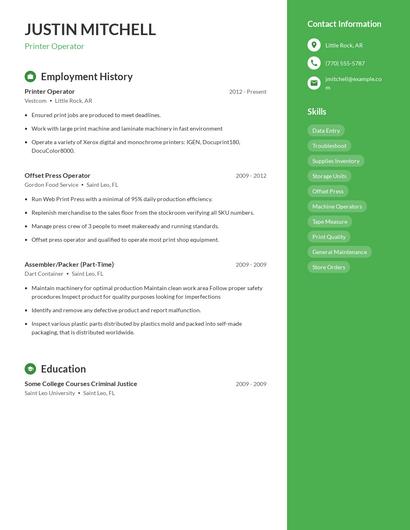

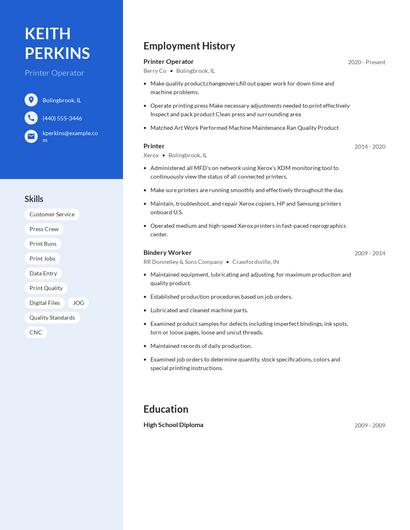

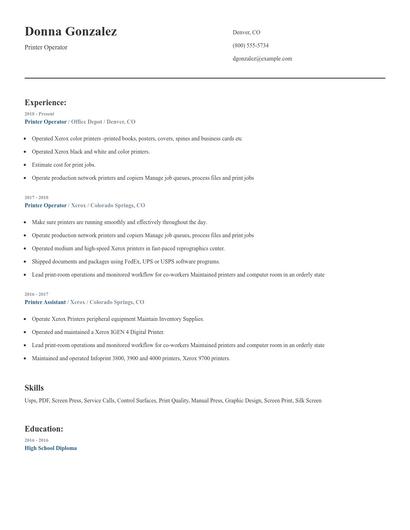

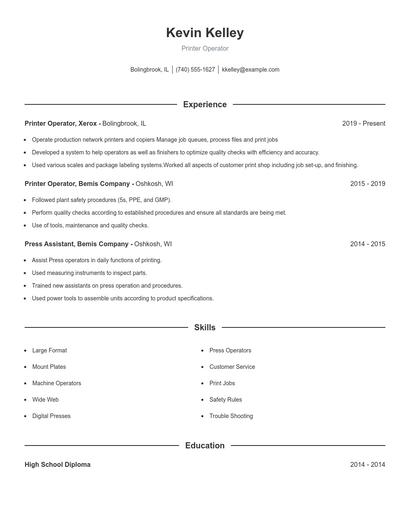

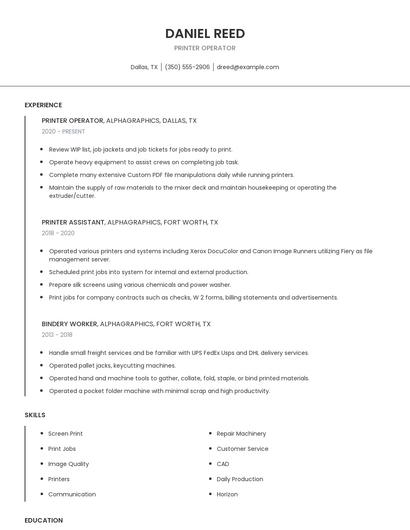

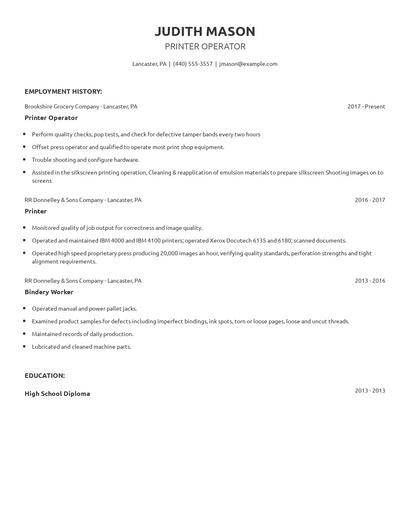

Choose from 10+ customizable printer operator resume templates

Build a professional printer operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your printer operator resume.Compare different printer operators

Printer operator vs. 2nd pressman

A pressman is responsible for maintaining the printing press operations, maintaining the efficiency of the equipment and machinery to produce high-quality outputs. Pressmen ensure the readability and completeness of the content before distribution. They must be knowledgeable of the mechanical industry, spotting inconsistencies with the equipment, and performing immediate repairs or component replacement to avoid delays in operation. A pressman works closely with other printing operators to ensure that the outputs meet the clients' specifications and business' printing guidelines.

There are some key differences in the responsibilities of each position. For example, printer operator responsibilities require skills like "work ethic," "quality checks," "quality standards," and "basic math." Meanwhile a typical 2nd pressman has skills in areas such as "lean manufacturing," "ink fountains," "preventative maintenance," and "kba." This difference in skills reveals the differences in what each career does.

2nd pressmen tend to reach similar levels of education than printer operators. In fact, 2nd pressmen are 0.7% less likely to graduate with a Master's Degree and 0.1% less likely to have a Doctoral Degree.Printer operator vs. Roll tender

A screen making technician performs installations and repairs to maintain the smooth flow of operations at manufacturing facilities. Their responsibilities typically include conducting measurements and assessments, setting guidelines, troubleshooting problems, gathering and analyzing data, and maintaining records of all procedures and adjustments. They must also maintain an active communication line with co-workers to ensure a safe and efficient work environment. Moreover, a screen making technician provides technical support to different teams while implementing company standards and regulations.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that printer operator responsibilities requires skills like "troubleshoot," "work ethic," "quality standards," and "windows." But a roll tender might use other skills in their typical duties, such as, "load paper," "load rolls," "clean press," and "hand tools."

Roll tenders may earn a lower salary than printer operators, but roll tenders earn the most pay in the media industry with an average salary of $36,580. On the other hand, printer operators receive higher pay in the technology industry, where they earn an average salary of $39,465.roll tenders earn similar levels of education than printer operators in general. They're 0.4% less likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.Printer operator vs. Pressman

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a printer operator is likely to be skilled in "troubleshoot," "work ethic," "quality checks," and "basic math," while a typical pressman is skilled in "safety regulations," "preventative maintenance," "web press," and "multi."

When it comes to education, pressmen tend to earn similar degree levels compared to printer operators. In fact, they're 0.5% less likely to earn a Master's Degree, and 0.3% less likely to graduate with a Doctoral Degree.Printer operator vs. Screen making technician

Types of printer operator

Updated January 8, 2025