What does a process design engineer do?

A Process Design Engineer designs various products, including required calculation, component selection, and determining the methods of construction. They are responsible for the safety management of the projects.

Process design engineer responsibilities

Here are examples of responsibilities from real process design engineer resumes:

- Manage the development of the next generation products base on existing refrigerants and CO2 system including prototyping and initial manufacturing run.

- Train with (and used extensively) Hitachi SEM.

- Facilitate HAZOP reviews and take lead responsibility for resolving issues.

- Create multiple SolidWorks assemblies to ensure parts fit within tolerance ranges.

- Apply image processing (using ImageJ) to analyse SEM image data.

- Design sheet metal assemblies in SolidWorks, complete drawings for these large assemblies.

- Help define and evaluate safety requirements using chemical compatibility, HAZOP and LOPA.

- Employ advanced processing techniques of reactive distillation and reactive extraction to favorably shift equilibrium of reactions involve in the process.

- Validate and rate distillation columns to determine column capacity.

- Specify PCB trace dimensions to implement constant impedance signal traces for optimize signal integrity

- Charge with providing technical leadership in the development, implementation, and integration of analog subsystems for high- speed communications.

- Scale microprocessor design-in successes across market by working with distributor field application engineers.

- Conduct customer training focuse on microprocessors and software at several corporate tech day market events.

Process design engineer skills and personality traits

We calculated that 6% of Process Design Engineers are proficient in Project Management, Process Engineering, and CAD. They’re also known for soft skills such as Speaking skills, Writing skills, and Creativity.

We break down the percentage of Process Design Engineers that have these skills listed on their resume here:

- Project Management, 6%

Advanced from production engineering group to support the pet food group project director with technical design details and project management.

- Process Engineering, 6%

Provide Process Engineering support to sales group by performing preliminary design calculations, reviewing customer specifications, and obtaining technical quotes.

- CAD, 5%

Developed graphic data compression/expansion and translation algorithms for use with CAD, CAM, CALS, facsimile, and document architecture.

- IDS, 4%

Reviewed P & IDs and Conducted assigned process design, prepared engineering calculations.

- Sigma, 4%

Incorporated Six Sigma methodology and principles by using the DMACIC process for quality and productivity improvement.

- Process Improvement, 4%

Created reports based on analysis & process improvement recommendations without jeopardizing risk to the portfolio while improving customer and associate experience.

Common skills that a process design engineer uses to do their job include "project management," "process engineering," and "cad." You can find details on the most important process design engineer responsibilities below.

Speaking skills. The most essential soft skill for a process design engineer to carry out their responsibilities is speaking skills. This skill is important for the role because "industrial engineers sometimes have to explain their instructions to production staff or technicians before they can make written instructions available." Additionally, a process design engineer resume shows how their duties depend on speaking skills: "root causes were addressed by a combination of kaizen efforts and leadership direction. "

Writing skills. Many process design engineer duties rely on writing skills. "industrial engineers must prepare documentation for other engineers or scientists, or for future reference," so a process design engineer will need this skill often in their role. This resume example is just one of many ways process design engineer responsibilities rely on writing skills: "identified and lead team in procedure/process changes/writing and validation. "

Creativity. process design engineers are also known for creativity, which are critical to their duties. You can see how this skill relates to process design engineer responsibilities, because "industrial engineers use creativity and ingenuity to design new production processes in many kinds of settings in order to reduce the use of material resources, time, or labor while accomplishing the same goal." A process design engineer resume example shows how creativity is used in the workplace: "assisted cost reduction coordinators in their efforts to minimize inventory. "

Listening skills. For certain process design engineer responsibilities to be completed, the job requires competence in "listening skills." The day-to-day duties of a process design engineer rely on this skill, as "these engineers often operate in teams, but they also must solicit feedback from customers, vendors, and production staff." For example, this snippet was taken directly from a resume about how this skill applies to what process design engineers do: "communicated with vendors and customers for product development. "

Math skills. A commonly-found skill in process design engineer job descriptions, "math skills" is essential to what process design engineers do. Process design engineer responsibilities rely on this skill because "industrial engineers use the principles of calculus, trigonometry, and other advanced topics in mathematics for analysis, design, and troubleshooting in their work." You can also see how process design engineer duties rely on math skills in this resume example: "applied principles of lean six sigma and statistics to reduce manufacturing downtime. "

Problem-solving skills. Another skill commonly found on process design engineer job descriptions is "problem-solving skills." It can come up quite often in process design engineer duties, since "in designing facilities for manufacturing and processes for providing services, these engineers deal with several issues at once, from workers’ safety to quality assurance." Here's an example from a resume of how this skill fits into day-to-day process design engineer responsibilities: "developed pids, hazop resolutions, interacted with piping and other disciplines to progress the project. "

The three companies that hire the most process design engineers are:

- Burns & McDonnell5 process design engineers jobs

- CITGO Petroleum4 process design engineers jobs

- Gilead Sciences3 process design engineers jobs

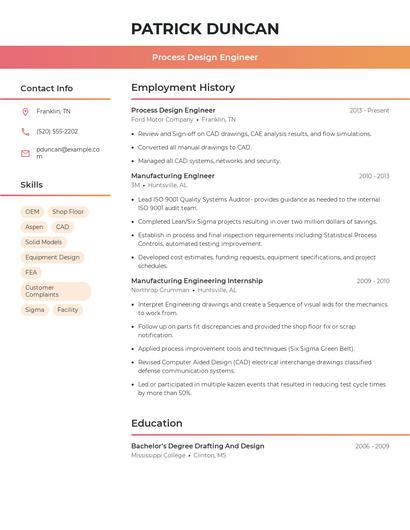

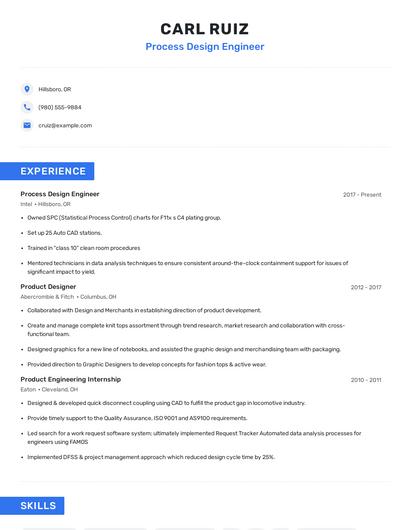

Choose from 10+ customizable process design engineer resume templates

Build a professional process design engineer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your process design engineer resume.Compare different process design engineers

Process design engineer vs. Quality control engineer

A quality control engineer is responsible for conducting quality assessments for the company's products and services to ensure adherence to federal regulations and quality standards. Quality control engineers recommend strategic methods by analyzing processes and writing test results. They also identify opportunities for more services that meet public demands and market trends, helping the business generate more resources for revenues. A quality control engineer utilizes various software tools and applications to document findings, requiring them to have excellent communication and technical skills.

While similarities exist, there are also some differences between process design engineers and quality control engineer. For instance, process design engineer responsibilities require skills such as "project management," "process engineering," "cad," and "ids." Whereas a quality control engineer is skilled in "quality standards," "corrective action," "continuous improvement," and "test procedures." This is part of what separates the two careers.

Quality control engineers really shine in the technology industry with an average salary of $83,131. Comparatively, process design engineers tend to make the most money in the energy industry with an average salary of $101,228.On average, quality control engineers reach similar levels of education than process design engineers. Quality control engineers are 0.5% less likely to earn a Master's Degree and 0.9% less likely to graduate with a Doctoral Degree.Process design engineer vs. Quality engineer

A quality engineer's responsibilities include ensuring that the manufacturing processes are efficient and accurate, documenting findings that would raise concerns, conducting quality tests while observing parameters, and implementing changes as necessary to meet the highest quality standards. Quality engineers need to have excellent problem-solving and observation skills to detect any irregularities and possible malfunctions. They also must be able to communicate effectively with the clients for feedbacks and corrective adjustments, address complaints, and immediately resolve any inconsistencies made.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that process design engineer responsibilities requires skills like "project management," "process engineering," "cad," and "ids." But a quality engineer might use other skills in their typical duties, such as, "corrective action," "continuous improvement," "quality standards," and "quality issues."

Quality engineers may earn a lower salary than process design engineers, but quality engineers earn the most pay in the technology industry with an average salary of $84,890. On the other hand, process design engineers receive higher pay in the energy industry, where they earn an average salary of $101,228.quality engineers earn similar levels of education than process design engineers in general. They're 1.0% more likely to graduate with a Master's Degree and 0.9% less likely to earn a Doctoral Degree.What technology do you think will become more important and prevalent for process design engineers in the next 3-5 years?

Associate Professor, The Ohio State University

Process design engineer vs. Engineer

Engineers are highly trained professionals who determine the feasibility of various projects, usually related to the construction industry. They are considered experts in mathematics and science, two disciplines that they need to use in designing and coming up with plans for projects. They should also be well-versed in different construction or industrial materials, and they ensure that appropriate materials are used for the project. They also ensure that the projects meet the requirements of the groups that hired them. They create spaces that would both address the needs of the end-users and the industry standards. They also ensure that the projects they make would stand the test of time.

The required skills of the two careers differ considerably. For example, process design engineers are more likely to have skills like "process engineering," "ids," "sigma," and "process improvement." But a engineer is more likely to have skills like "python," "cloud," "c++," and "c #."

Engineers earn the highest salary when working in the automotive industry, where they receive an average salary of $97,672. Comparatively, process design engineers have the highest earning potential in the energy industry, with an average salary of $101,228.engineers typically earn similar educational levels compared to process design engineers. Specifically, they're 0.9% more likely to graduate with a Master's Degree, and 0.5% more likely to earn a Doctoral Degree.Process design engineer vs. Industrial engineer

An industrial engineer specializes in devising various systems to improve the workflow and the workforce in a manufacturing setting. One of their primary responsibilities is to understand all of the procedures in a manufacturing plant and develop strategies to resolve issues or improve production operations, such as designing a cost-efficient machine or system that will enhance the quality of goods and boost the productivity of workers. Moreover, it is also essential to adhere to all the company's policies and safety regulations to maintain a safe and productive work environment for all employees.

Even though a few skill sets overlap between process design engineers and industrial engineers, there are some differences that are important to note. For one, a process design engineer might have more use for skills like "process engineering," "ids," "heat exchangers," and "process simulation." Meanwhile, some responsibilities of industrial engineers require skills like "continuous improvement," "lean manufacturing," "excellent interpersonal," and "logistics. "

In general, industrial engineers earn the most working in the technology industry, with an average salary of $83,503. The highest-paying industry for a process design engineer is the energy industry.industrial engineers reach similar levels of education compared to process design engineers, in general. The difference is that they're 0.4% more likely to earn a Master's Degree, and 1.6% less likely to graduate with a Doctoral Degree.Types of process design engineer

Updated January 8, 2025