What does a process engineering technician do?

A process engineering technician typically works at manufacturing facilities where they are in charge of providing technical support to engineers in an effort to optimize production operations. Their responsibilities usually include performing installations and adjustments, developing and implementing test structures, understanding blueprints and schematics, replacing components, troubleshooting problems, recommending solutions, and repairing parts as needed. A process engineering technician typically works in a team setting, which requires an active communication line for a smooth and efficient workflow.

Process engineering technician responsibilities

Here are examples of responsibilities from real process engineering technician resumes:

- Lead a team, scheduling, resource planning, to create 120 catheters on schedule for a clinical trial.

- Perform IQ and OQ validations for both equipments.

- Design and build test facilities for RF and electronic products.

- Conduct SPC analysis and conduct ISO internal audits to ensure compliance.

- Provide on the floor engineering support for upstream and start-up GMP manufacturing.

- Track all equipment changes for cost, schedule and GMP impacts to project.

- Train as a six sigma green belt and successfully complete a $90k/yr energy reduction project.

- Edit ISO certify work instructions to include the new processes as well as modifications to the existing processes.

- Perform equipment and process qualifications as per establish protocols (OQ, PQ, IQ & EQ).

- Perform the cleaning process of tanks used in the IBP area by the utilization of the CIP process.

- Assist with characterization of CMOS photolithography process and optimize focus and exposure settings for all layers.

- Confer with management; production planner to determine manufacturing feasibility, and customer demand for prototype and exiting say products.

- Establish and monitor data streams for improving KPI's across the SQDC platform.

- Design and execute laboratory and pilot scale experiments in harvest and cell culture.

Process engineering technician skills and personality traits

We calculated that 11% of Process Engineering Technicians are proficient in Process Engineering, Continuous Improvement, and Process Improvement. They’re also known for soft skills such as Analytical skills, Communication skills, and Detail oriented.

We break down the percentage of Process Engineering Technicians that have these skills listed on their resume here:

- Process Engineering, 11%

PROCESS ENGINEERING TECH Responsibilities included the monitoring, troubleshooting and repairing of automated manufacturing equipment used in the Semiconductor industry.

- Continuous Improvement, 8%

Implement and refine manufacturing processes by applying continuous improvement and lean/six sigma manufacturing principles to all areas of production.

- Process Improvement, 5%

Designed and conducted experiments to develop and optimize equipment operation parameters and responsible for many cost saving process improvements.

- R, 4%

Developed and used X-bar R charts to determine process variation for dry film thickness of paint process.

- Process Equipment, 3%

Collaborate with engineers to determine corrective action plans when experiencing difficulties with process equipment s.

- Technical Support, 3%

Provided technical support to marketing divisions and technical service with lab-based product test data.

"process engineering," "continuous improvement," and "process improvement" are among the most common skills that process engineering technicians use at work. You can find even more process engineering technician responsibilities below, including:

Analytical skills. One of the key soft skills for a process engineering technician to have is analytical skills. You can see how this relates to what process engineering technicians do because "industrial engineering technologists and technicians assess changes in conditions, operations, and the environment to help industrial engineers figure out how systems should work." Additionally, a process engineering technician resume shows how process engineering technicians use analytical skills: "generated, organized and provided metrology data to internal, external and international customers. "

Communication skills. Many process engineering technician duties rely on communication skills. "industrial engineering technologists and technicians must listen carefully to instructions from engineers and must clearly articulate problems to their supervisors.," so a process engineering technician will need this skill often in their role. This resume example is just one of many ways process engineering technician responsibilities rely on communication skills: "install, test, and upgrade electrical and mechanical, rf and communications systems on locomotive emd and g.e. "

Detail oriented. process engineering technicians are also known for detail oriented, which are critical to their duties. You can see how this skill relates to process engineering technician responsibilities, because "industrial engineering technologists and technicians must record precisely what they measure and observe." A process engineering technician resume example shows how detail oriented is used in the workplace: "sustained metrology tools (machines) in semiconductor environment where attention to detail was utilized. "

Math skills. process engineering technician responsibilities often require "math skills." The duties that rely on this skill are shown by the fact that "industrial engineering technologists and technicians use mathematics and statistical techniques to analyze data collected from studies." This resume example shows what process engineering technicians do with math skills on a typical day: "created math model leveraging ms excel to automate forehearth design and operations for new line within melting processes. "

The three companies that hire the most process engineering technicians are:

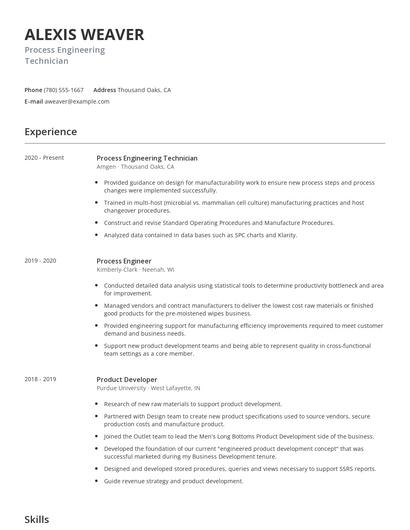

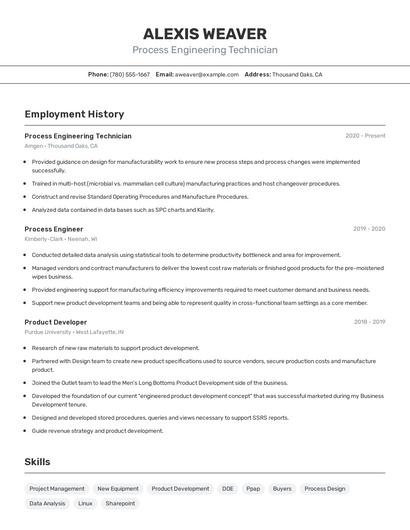

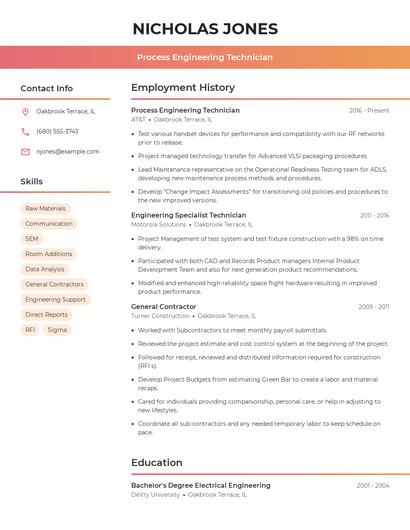

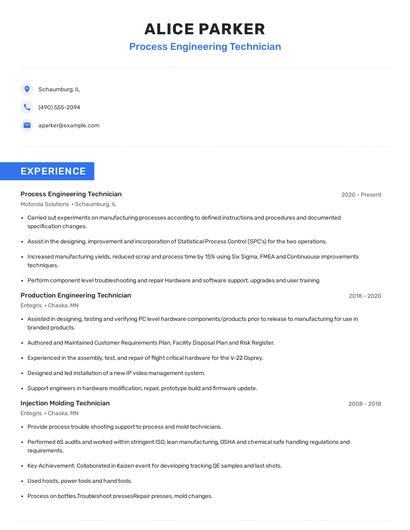

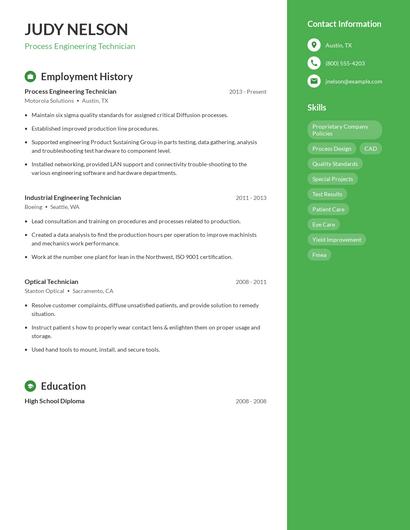

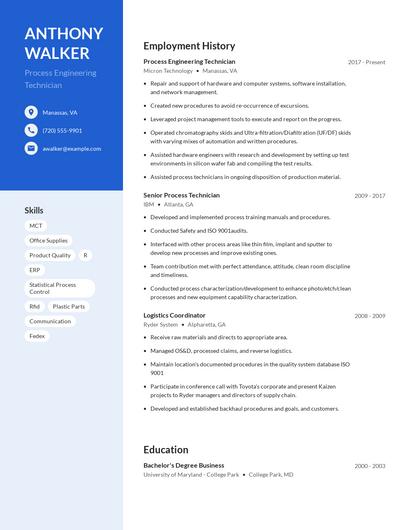

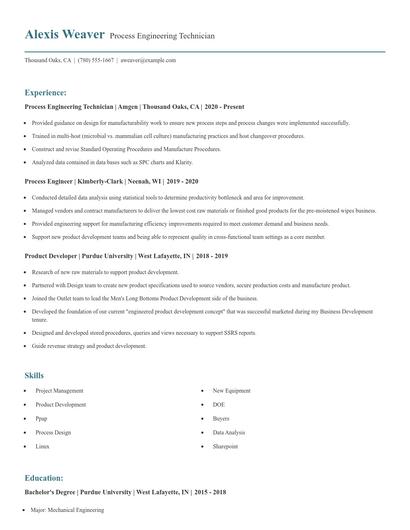

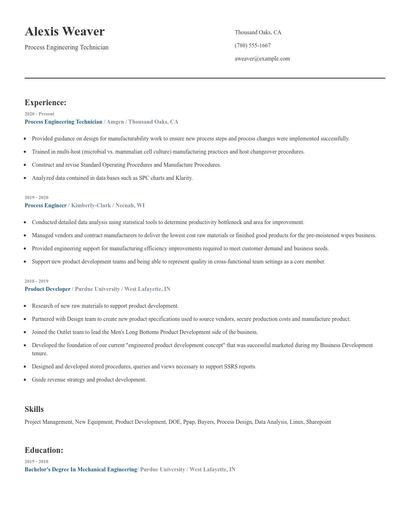

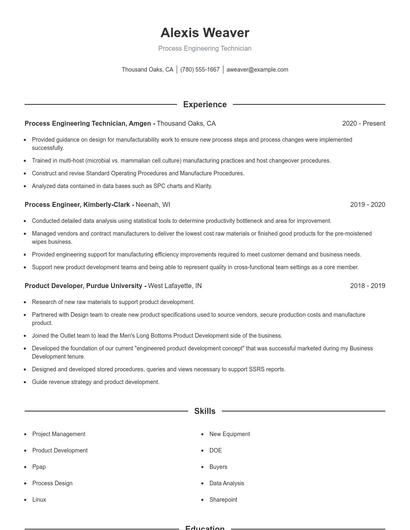

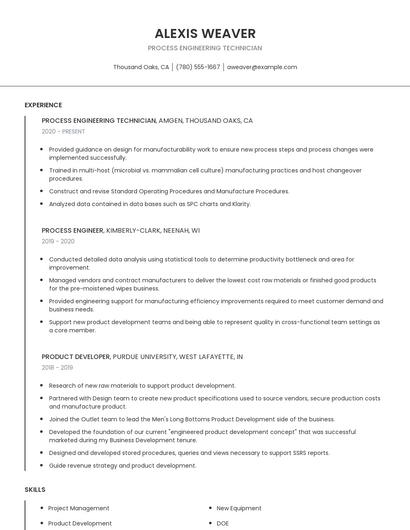

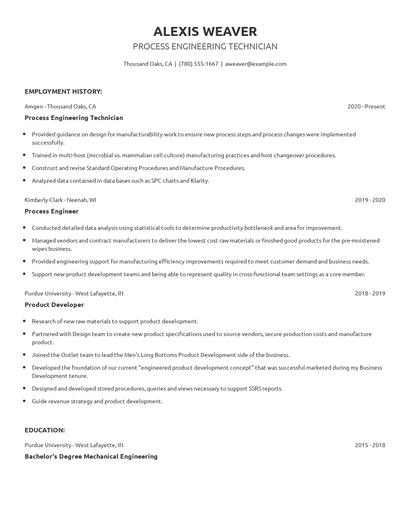

Choose from 10+ customizable process engineering technician resume templates

Build a professional process engineering technician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your process engineering technician resume.Compare different process engineering technicians

Process engineering technician vs. Validation technologist

A validation technologist works with a process chief and applies validation methods to complete tasks and carry out installations. They perform operational protocol duties and do reviews daily. They also analyze the validation test data to make sure it meets the necessary criteria for validation. They may have to generate and conduct all the phases in the validation process. These include IQs, OQ's and PQ's.

While similarities exist, there are also some differences between process engineering technicians and validation technologist. For instance, process engineering technician responsibilities require skills such as "process engineering," "continuous improvement," "process equipment," and "technical support." Whereas a validation technologist is skilled in "troubleshoot," "python," "test results," and "linux." This is part of what separates the two careers.

Validation technologists really shine in the technology industry with an average salary of $54,319. Comparatively, process engineering technicians tend to make the most money in the technology industry with an average salary of $92,986.On average, validation technologists reach similar levels of education than process engineering technicians. Validation technologists are 2.0% less likely to earn a Master's Degree and 1.2% less likely to graduate with a Doctoral Degree.Process engineering technician vs. Quality technician engineer

Quality specialists are quality assurance professionals who make sure that the organization's standards are constantly maintained in their products. They are employed in various industries, like technology and manufacturing. Their duties include planning quality standards, directing audits, providing recommendations to management on improving operations, as well as evaluating employee performance. It is their responsibility to ensure the current product quality specifications meet the client's requirements. Additionally, they identify product defects, conduct product tests and assessments, together with recording and reporting the issues.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that process engineering technician responsibilities requires skills like "process engineering," "continuous improvement," "process equipment," and "preventative maintenance." But a quality technician engineer might use other skills in their typical duties, such as, "process control," "supplier quality," "spc," and "quality system."

Quality technician engineers earn a higher average salary than process engineering technicians. But quality technician engineers earn the highest pay in the technology industry, with an average salary of $94,345. Additionally, process engineering technicians earn the highest salaries in the technology with average pay of $92,986 annually.quality technician engineers earn similar levels of education than process engineering technicians in general. They're 1.4% less likely to graduate with a Master's Degree and 1.2% less likely to earn a Doctoral Degree.Process engineering technician vs. Quality control technician

Usually assigned in a manufacturing plant, a quality control technician's role focuses on testing and assessing materials before, after, and during a production process to ensure its efficiency. They also have responsibilities in implementing the policies and regulations of the company, all to maintain a safe and productive working environment for every employee. Furthermore, a quality control technician must produce necessary reports and documentation, coordinate with managers and supervisors, maintain accurate documentation, and oversee a team to secure quality standard outcomes.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from process engineering technician resumes include skills like "process engineering," "continuous improvement," "process improvement," and "process equipment," whereas a quality control technician is more likely to list skills in "lab equipment," "quality control tests," "test results," and "asphalt. "

Quality control technicians earn the best pay in the health care industry, where they command an average salary of $45,814. Process engineering technicians earn the highest pay from the technology industry, with an average salary of $92,986.When it comes to education, quality control technicians tend to earn similar degree levels compared to process engineering technicians. In fact, they're 1.7% less likely to earn a Master's Degree, and 0.9% less likely to graduate with a Doctoral Degree.Process engineering technician vs. Quality laboratory technician

A Quality Laboratory Technician ensures that lab procedures and equipment meet a certain standard, as well as monitors production. They maintain quality service and a safe and healthy work environment through following organization standards.

Even though a few skill sets overlap between process engineering technicians and quality laboratory technicians, there are some differences that are important to note. For one, a process engineering technician might have more use for skills like "process engineering," "continuous improvement," "process improvement," and "process equipment." Meanwhile, some responsibilities of quality laboratory technicians require skills like "lab equipment," "quality lab," "test results," and "food safety. "

In general, quality laboratory technicians earn the most working in the manufacturing industry, with an average salary of $38,772. The highest-paying industry for a process engineering technician is the technology industry.The average resume of quality laboratory technicians showed that they earn similar levels of education compared to process engineering technicians. So much so that theyacirc;euro;trade;re 2.0% less likely to earn a Master's Degree and less likely to earn a Doctoral Degree by 0.8%.Types of process engineering technician

Updated January 8, 2025