What does a quality systems specialist do?

A quality systems specialist is responsible for conducting audit checks with the company's current quality systems and technologies to ensure adherence to regulatory policies and internal guidelines. Quality systems specialists evaluate the components of the system and recommend process improvement strategies, requiring them to have excellent technical skills to design or revise system interfaces. They also write comprehensive reports about the system's performance in meeting client requirements and determining usability to deliver outputs timely and efficiently.

Quality systems specialist responsibilities

Here are examples of responsibilities from real quality systems specialist resumes:

- Achieve AS9100 registration under new QMS.

- Manage TrackWise database, metrics, trends and training.

- Provide support for development and QA environments as well as manage test and production servers under strict change-control policies.

- Lead cross functional project team to build user-friendly windows base customer support applications which interface with the OmniPlan/OmniPlus mainframe application.

- Serve as a primary interface with ISO registrar and secondary interface to the outside certifying agencies and regulatory agencies.

- Assist in PowerPoint presentation projects.

- Maintain compliance of the QMS for company, customer, statutory and regulatory requirements.

- Support SME's with needs assessment, course design and development, course deployment.

- Develop the design control guideline for KMI/PAREXEL base on the CFR, AAMI and industries practice guidelines.

- Serve as a subject matter expert (SME) and mentor, and support activities in the area.

- Design and execute in-house training seminars and courses which range from GMP to investigative techniques utilizing DMAIC and DMADV principles.

- Coordinate third-party audits to review the health of divisional systems and processes as governed by ISO 9001:2008/AS9100C requirements across multiple sites.

- Conduct and lead internal/external QMS audits, out of specification (OOS), investigations, deviations, CAPA, etc.

- Monitor and report on quality data for CAPA, NCR, complains, material reviews, equipment calibration/PM and SPC trending.

- Participate in design and test planning reviews for new features and deployments, and represent QA in requirements analysis and review.

Quality systems specialist skills and personality traits

We calculated that 9% of Quality Systems Specialists are proficient in Quality System, FDA, and ISO. They’re also known for soft skills such as Interpersonal skills, Leadership skills, and Time-management skills.

We break down the percentage of Quality Systems Specialists that have these skills listed on their resume here:

- Quality System, 9%

Assist manufacturing site with the development and implementation of quality system remediation activities to achieve compliance with all applicable standards.

- FDA, 7%

Conducted audits of pharmaceutical suppliers evaluating compliance with FDA, customer purchase order and supplier requirements.

- ISO, 7%

Maintained ISO 9001 certification for business globally, overseeing audit program and advocating various continuous improvement efforts.

- Continuous Improvement, 7%

Design, implement and refine manufacturing process by applying continuous improvement and lean manufacturing principles to all areas of production.

- GMP, 6%

Assist Quality Assurance by handling and reviewing documentation associated with GMP regulations.

- Corrective Action, 5%

Performed corrective/preventive action effectiveness evaluations at appropriate intervals.

"quality system," "fda," and "iso" are among the most common skills that quality systems specialists use at work. You can find even more quality systems specialist responsibilities below, including:

Interpersonal skills. The most essential soft skill for a quality systems specialist to carry out their responsibilities is interpersonal skills. This skill is important for the role because "industrial production managers must have excellent communication skills to work well other managers and with staff." Additionally, a quality systems specialist resume shows how their duties depend on interpersonal skills: "demonstrate proven leadership ability and excellent interpersonal skills while mentoring and teaching the team effective problem solving. "

Leadership skills. Another soft skill that's essential for fulfilling quality systems specialist duties is leadership skills. The role rewards competence in this skill because "to keep the production process running smoothly, industrial production managers must motivate and direct employees." According to a quality systems specialist resume, here's how quality systems specialists can utilize leadership skills in their job responsibilities: "published and presented quarterly site quality metrics to site leadership. "

Problem-solving skills. A big part of what quality systems specialists do relies on "problem-solving skills." You can see how essential it is to quality systems specialist responsibilities because "production managers must identify and address problems that arise." Here's an example of how this skill is used from a resume that represents typical quality systems specialist tasks: "supervised multiple locations on qms/problem resolution, gaining plexus corporation trainer/coach for iso 9001-2000 training certification. "

The three companies that hire the most quality systems specialists are:

- Boeing29 quality systems specialists jobs

- KARL STORZ Endoscopy

23 quality systems specialists jobs

- BD16 quality systems specialists jobs

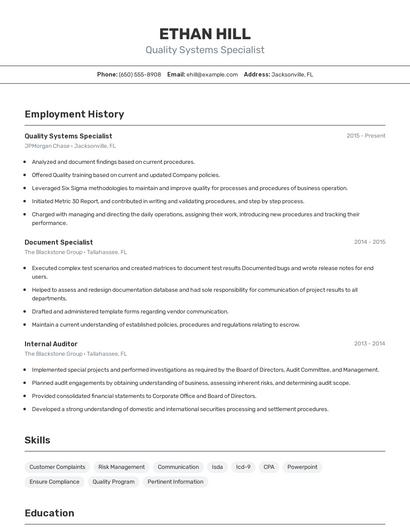

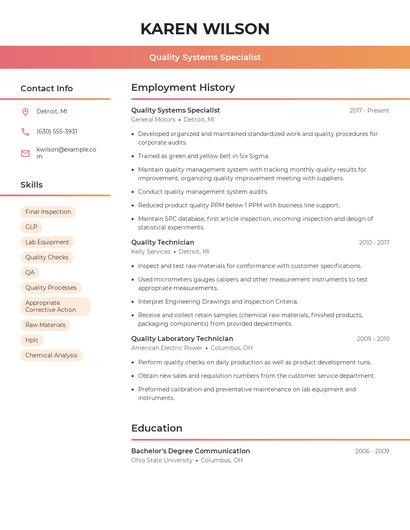

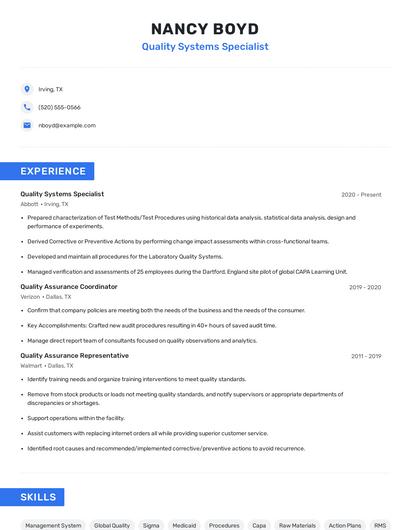

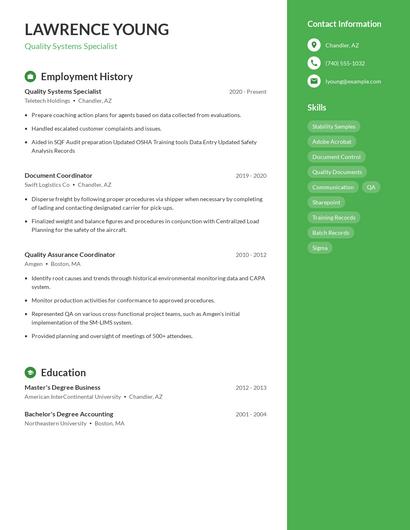

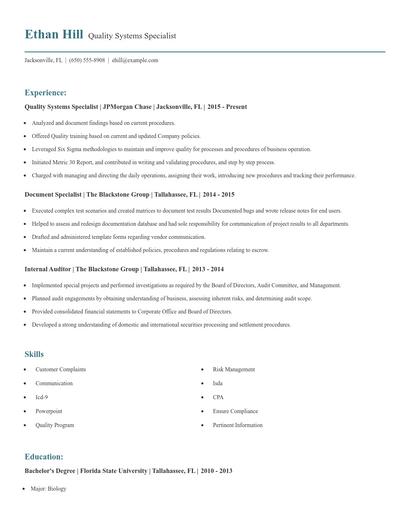

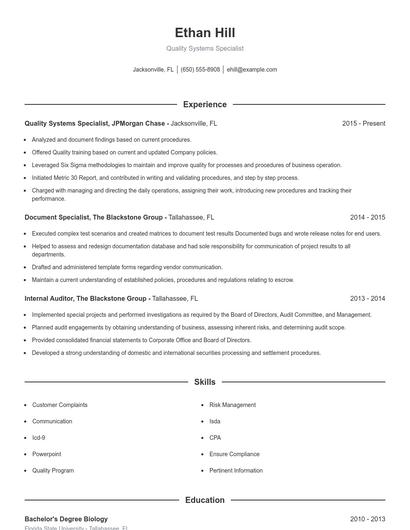

Choose from 10+ customizable quality systems specialist resume templates

Build a professional quality systems specialist resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your quality systems specialist resume.Compare different quality systems specialists

Quality systems specialist vs. Laboratory manager

Laboratory managers provide accurate laboratory diagnosis through evaluating specimen procedures and coordinating with pathologists to validate laboratory findings. They are responsible for maintaining laboratory tools and equipment, ensuring the proper sterilization of instruments before and after use, organizing equipment based on its function, and immediately repairing or replacing defective items. A laboratory manager also secures the confidentiality of laboratory systems, keeping records of results, and releasing information to the appropriate personnel. Laboratory managers must have a broad knowledge of the scientific industry, as well as excellent analytical and critical-thinking skills.

These skill sets are where the common ground ends though. The responsibilities of a quality systems specialist are more likely to require skills like "quality system," "continuous improvement," "qms," and "process improvement." On the other hand, a job as a laboratory manager requires skills like "lab equipment," "patients," "customer service," and "chemistry." As you can see, what employees do in each career varies considerably.

Laboratory managers tend to make the most money working in the pharmaceutical industry, where they earn an average salary of $90,911. In contrast, quality systems specialists make the biggest average salary, $83,572, in the health care industry.The education levels that laboratory managers earn slightly differ from quality systems specialists. In particular, laboratory managers are 1.6% less likely to graduate with a Master's Degree than a quality systems specialist. Additionally, they're 3.1% more likely to earn a Doctoral Degree.Quality systems specialist vs. Director of quality

In the manufacturing industry, a director of quality is primarily in charge of spearheading and overseeing the daily operations in a quality assurance department. They work to ensure that products adhere to the company's quality standards and industry regulations by conducting research and assessments, developing quality test systems, and reviewing reports. As a director of quality, they have the authority to make significant decisions, establish protocols and guidelines, set objectives and timelines, and implement rules and policies, creating new ones as necessary.

Each career also uses different skills, according to real quality systems specialist resumes. While quality systems specialist responsibilities can utilize skills like "quality system," "qms," "management review," and "powerpoint," directors of quality use skills like "healthcare," "quality improvement," "patients," and "oversight."

Directors of quality earn a higher average salary than quality systems specialists. But directors of quality earn the highest pay in the finance industry, with an average salary of $155,704. Additionally, quality systems specialists earn the highest salaries in the health care with average pay of $83,572 annually.directors of quality earn higher levels of education than quality systems specialists in general. They're 7.9% more likely to graduate with a Master's Degree and 3.1% more likely to earn a Doctoral Degree.Quality systems specialist vs. Quality assurance auditor

Quality assurance (QA) analysts are responsible for testing company products and processes. Through testing, QA analysts ensure that the product or process is ready for production. They check whether the process meets company standards and guidelines, as well as any standards related to the industry they are in. QA analysts are in charge of determining the root cause of any problems that they may encounter. They also try to solve these as soon as possible. They also ensure that the company's products meet user expectations as well as the company's brand promise.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from quality systems specialist resumes include skills like "continuous improvement," "management review," "data analysis," and "quality metrics," whereas a quality assurance auditor is more likely to list skills in "patients," "clinical trials," "quality assurance audits," and "glp. "

Quality assurance auditors earn the best pay in the pharmaceutical industry, where they command an average salary of $87,841. Quality systems specialists earn the highest pay from the health care industry, with an average salary of $83,572.quality assurance auditors typically earn lower educational levels compared to quality systems specialists. Specifically, they're 5.1% less likely to graduate with a Master's Degree, and 0.9% less likely to earn a Doctoral Degree.Quality systems specialist vs. Quality control manager

A quality control manager is responsible for checking the quality of products and materials, especially for release and delivery, ensuring that the items are free of any defects. Quality control managers coordinate with other organization heads to develop effective processes to maintain and improve the products' efficiency, following the regulatory procedures and standard protocols. They monitor production, identify areas of improvement, inspect the finished products, and adjust product development techniques based on the client's specifications. A quality control manager must have excellent communication and leadership skills to handle the production team and address concerns immediately.

Types of quality systems specialist

Updated January 8, 2025