What does a roll operator do?

A roll operator operates a rolling machine used to bend metal plates, sheets, or metal bars into different shapes adhering to specific blueprints, templates, and their knowledge in geometry. They used designs to make models used in the construction of different structures. Their duties and responsibilities include installing the equipment needed, manipulating controls to achieve required outputs, and measuring raw materials.

Roll operator responsibilities

Here are examples of responsibilities from real roll operator resumes:

- Run high temperature pressure to produce mold plastic pallets.

- Document maintenance reports, log sheet, QA checks and production.

- Verify conformance to specifications, using micrometers, gauges and calipers.

- Exhibit high levels of accuracy, speed, attention to detail and math skills.

- Operate steel wheel rollers, rubber tire rollers, loaders, and similar equipment.

- Operate and maintain a forklift, bobcat, backhoe/front-end loader and grader in a safe and efficient manner.

- Use forklifts and hoists to get steel coils setup to run through the machines to be cut and form.

- Ensure that the proper measurements are recorded and that the proper amounts of lime rock and asphalt are laid and set.

- Operate heavy machinery such as bobcat equipment and also operate and pave asphalt perform demolition work.

- Use of overhead crane, loading coils of steel and weld with an arc welder.

- Operate and maintain a forklift, bobcat, backhoe/front-end loader and grader in a safe and efficient manner.

Roll operator skills and personality traits

We calculated that 30% of Roll Operators are proficient in Asphalt, Construction Sites, and Hand Tools. They’re also known for soft skills such as Computer skills, Dexterity, and Physical strength.

We break down the percentage of Roll Operators that have these skills listed on their resume here:

- Asphalt, 30%

Dumped, spread, and tamp asphalt, using pneumatic tampers, to repair joints and patch broken pavement.

- Construction Sites, 8%

Truck Driver/Water Truck Driver- Deliver materials to construction sites and to residential sites.

- Hand Tools, 5%

Cut materials, such as textiles, using hand tools, portable power tools and bench-mounted tools.

- Hot Mix, 5%

Compact hot mix to specific density to meet TXDOT standards.

- Tape Measure, 5%

Utilized tape measure to check holes pattern.

- CDL, 5%

Have CDL would drive swab unit to job and rig up and swab well in then turn it over to production

Common skills that a roll operator uses to do their job include "asphalt," "construction sites," and "hand tools." You can find details on the most important roll operator responsibilities below.

Computer skills. One of the key soft skills for a roll operator to have is computer skills. You can see how this relates to what roll operators do because "metal and plastic machine workers must be able to use programmable devices, computers, and robots on the factory floor." Additionally, a roll operator resume shows how roll operators use computer skills: "monitor quality with calipers, micrometers, computers, by sight, and tape measures. "

Physical strength. This is an important skill for roll operators to perform their duties. For an example of how roll operator responsibilities depend on this skill, consider that "metal and plastic machine workers must be able to secure and tighten heavy fixtures into place." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a roll operator: "preformed physical and computer quality checks to maintain a bottle that were within the specs provided by the customer. ".

Mechanical skills. roll operator responsibilities often require "mechanical skills." The duties that rely on this skill are shown by the fact that "these workers must be comfortable with machines and have a good understanding of how all the parts work." This resume example shows what roll operators do with mechanical skills on a typical day: "qualified quality operator* qualified saw operator* qualified extrusion operator* mechanical and electrical repair"

The three companies that hire the most roll operators are:

- Sheridan38 roll operators jobs

- TPI33 roll operators jobs

- Oldcastle Infrastructure17 roll operators jobs

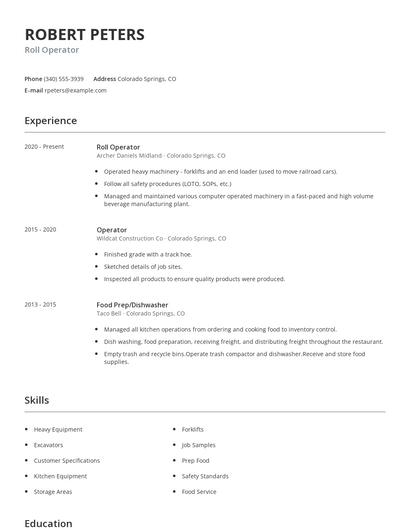

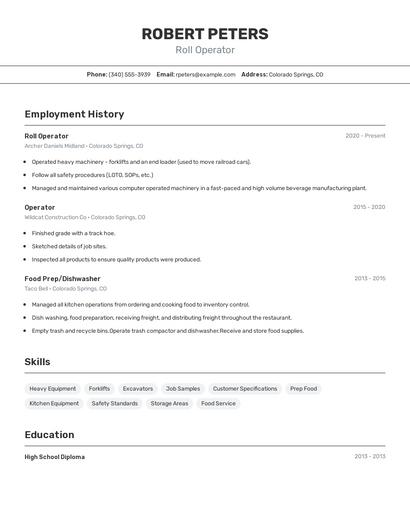

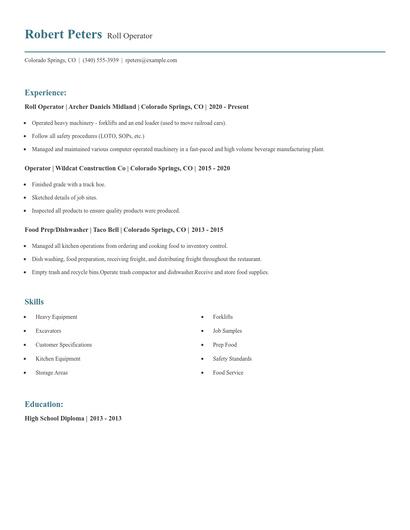

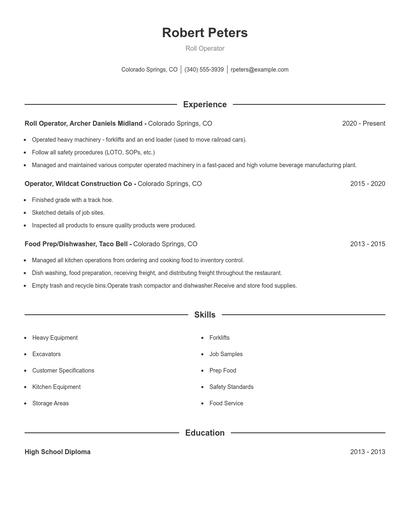

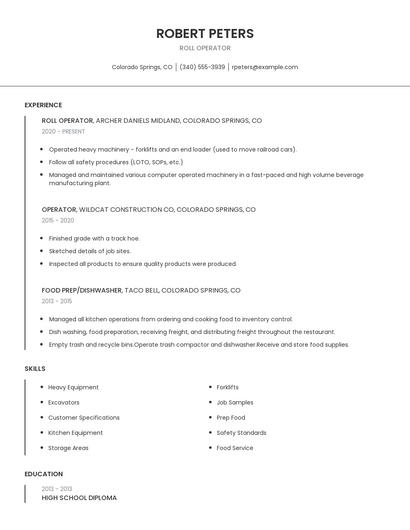

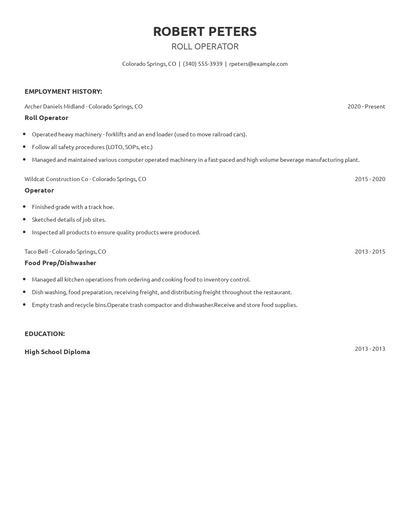

Choose from 10+ customizable roll operator resume templates

Build a professional roll operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your roll operator resume.Compare different roll operators

Roll operator vs. First leveler

A machine operator/forklift operator is responsible for operating industrial trucks to move merchandise around the warehouse facilities and other assigned areas. Machine operators/forklift operators also assist with inventory tasks by scanning orders and ensuring the correct merchandise for shipment. They manage the stability of the vehicles, ensuring its efficiency and optimization during operations, performing engine repairs for any inconsistencies to avoid delays on deliveries. A machine operator/forklift operator should strictly follow the safety protocols of the business, as well as have knowledge of the mechanical industry.

While similarities exist, there are also some differences between roll operators and first leveler. For instance, roll operator responsibilities require skills such as "asphalt," "construction sites," "hand tools," and "hot mix." Whereas a first leveler is skilled in "level support," "troubleshoot," "technical support," and "printers." This is part of what separates the two careers.

First levelers tend to reach higher levels of education than roll operators. In fact, first levelers are 7.3% more likely to graduate with a Master's Degree and 2.8% more likely to have a Doctoral Degree.Roll operator vs. Machine operator/forklift operator

In addition to the difference in salary, there are some other key differences worth noting. For example, roll operator responsibilities are more likely to require skills like "asphalt," "construction sites," "hand tools," and "hot mix." Meanwhile, a machine operator/forklift operator has duties that require skills in areas such as "safety standards," "drive forklift," "load trucks," and "machine operation." These differences highlight just how different the day-to-day in each role looks.

On average, machine operator/forklift operators earn a lower salary than roll operators. Some industries support higher salaries in each profession. Interestingly enough, machine operator/forklift operators earn the most pay in the automotive industry with an average salary of $36,711. Whereas roll operators have higher pay in the manufacturing industry, with an average salary of $39,490.machine operator/forklift operators earn similar levels of education than roll operators in general. They're 0.5% less likely to graduate with a Master's Degree and 2.8% more likely to earn a Doctoral Degree.Roll operator vs. Steel roller

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a roll operator is likely to be skilled in "construction sites," "hand tools," "hot mix," and "tape measure," while a typical steel roller is skilled in "control systems," "proactive," "wire-up," and "multimeters."

Most steel rollers achieve a similar degree level compared to roll operators. For example, they're 1.0% less likely to graduate with a Master's Degree, and 0.0% less likely to earn a Doctoral Degree.Roll operator vs. Tube roller

Types of roll operator

Updated January 8, 2025