Automatically apply for jobs with Zippia

Upload your resume to get started.

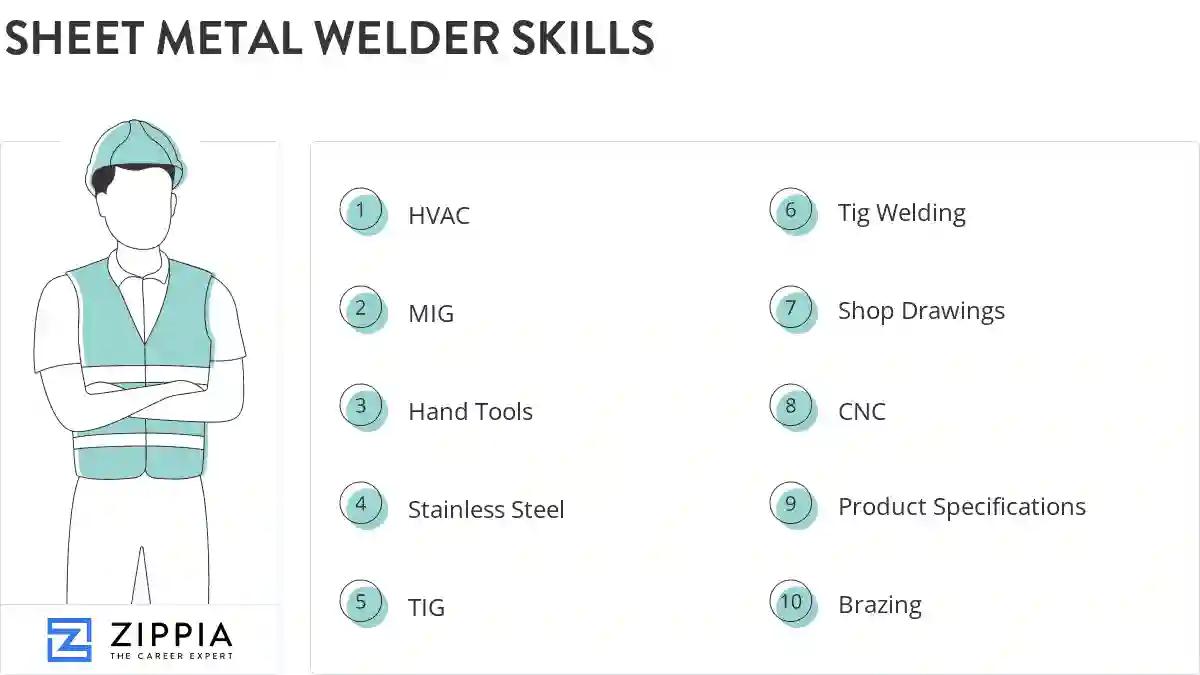

Sheet metal welder skills for your resume and career

15 sheet metal welder skills for your resume and career

1. HVAC

- Read Blueprints - Sheet metal welding/ plasma cutting - Sheet metal shear - Insulating HVAC curbs

- Welded Installed HVAC Installed McDonalds kitchens Installed sheet metal Gutters Flashing, Counter Flashing, Metal Era, etc.

2. MIG

MIG is a specific type of welding in which two base materials are welded together using a solid wire electrode fed through a welding gun and into the weld pool.

- Skilled in installation / welding Accomplishments Welding School stick and Mig

- Type of Welding: > Mig: Flux-core and stainless steel > Stick: 7018 11018 and 6011.

3. Hand Tools

- Fabricated and assembled custom built products according to work orders using hand tools, power tools and metal working machinery.

- Trim, file, grind, debar, buff and smooth surfaces using hand tools and portable power tools.

4. Stainless Steel

Stainless steel is an alloy of iron, chromium, carbon, and some other metals with corrosion-resistant properties. The components of steel include less than 1% carbon, 1% manganese, and small quantities of other elements such as phosphorus, silicon, sulfur, and oxygen. Iron and carbon are the two essential components of steel. Stainless steel is resistant to tarnishing and rust.

- Name of business The Portable Stainless Steel Guy.

- Operated plasma machine for 4 years on night shift in shop/layed out and welded stainless steel elbows and fittings

5. TIG

TIG stands for "tungsten inert gas welding" and is also known as gas tungsten arc welding (GTAW). This particular type of weld is more difficult as it requires the welder to heat materials until they are liquid.

- Experience in construction / maintenance history * Experience in TIG welding and fabrication.

- Sheet metal (TIG) welder for various industrial kitchens

6. Tig Welding

- Measured materials Analyzed blue prints Operated power tools used for drilling and tig welding.

Choose from 10+ customizable sheet metal welder resume templates

Build a professional sheet metal welder resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your sheet metal welder resume.7. Shop Drawings

- Convert blueprints into shop drawings to be followed in the construction and assembly of sheet metal products.

- Performed custom sheet metal fabrication, structural steel work, welding, pipe fabrication and layout, and shop drawing production.

8. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Utilized machine precision tools to exact tolerances using sophisticated CNC machinery.

- Work with computer numeric controlled (CNC) heavy machinery from setup to operation to produce parts and tools from metal.

9. Product Specifications

A product specification is a document detailing all the requirements and key features of a product that's about to be built. It's mostly called a blueprint because it's the product in its theoretical form which is also the preliminary stage of product design.

- Green Task Statement Selected gauges or types of sheet metal or nonmetallic material, according to product specifications.

- Performed Quality assurance inspections on all products to ensure conformance with product specifications.

10. Brazing

- Performed installations, copper brazing, and mechanical tasks associated with commercial construction

- Utilized oxygen soldering for brazing.

11. GMAW

- Utilized a variety of welding techniques to include-SMAW, FLAW and GMAW.

12. SMAW

- Used the SMAW, GMAW and GTAW welding processes to weld different types of material.

13. Arc Welding

- Performed gas/tungsten/arc welding on aircraft.

- Skilled with gas tungsten arc, gas metal arc, flux-cored arc, shielded metal arc, and submerged arc welding.

14. Jigs

- Set up jigs to weld pallets for individual orders, also marked measured and stamped material for jobs.

- Fabricate various jigs for various stools and chairs, school desks and cages.

15. Dividers

- Used measuring devices and layout tools such as calculators, scribes, dividers, squares, rulers, templates, compasses.

- Removed and replaced seats and class dividers.

5 Sheet Metal Welder resume examples

Build a professional sheet metal welder resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your sheet metal welder resume.

What skills help Sheet Metal Welders find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of sheet metal welder skills to add to your resume

The most important skills for a sheet metal welder resume and required skills for a sheet metal welder to have include:

- HVAC

- MIG

- Hand Tools

- Stainless Steel

- TIG

- Tig Welding

- Shop Drawings

- CNC

- Product Specifications

- Brazing

- GMAW

- SMAW

- Arc Welding

- Jigs

- Dividers

- Punch Press

Updated January 8, 2025