What does a tool technician do?

Tool technicians are skilled professionals who are responsible for repairing a variety of pneumatic and hand tools as well as disassemble defective electrical equipment in a manufacturing firm using these hand tools. These technicians are required to coordinate with other areas of the company to schedule and perform preventive maintenance duties. They must provide support for CNC operators by setting up the caliper and micrometer of all the CNC machines. Tool technicians must also assist coworkers in ordering materials and purchasing machine parts.

Tool technician responsibilities

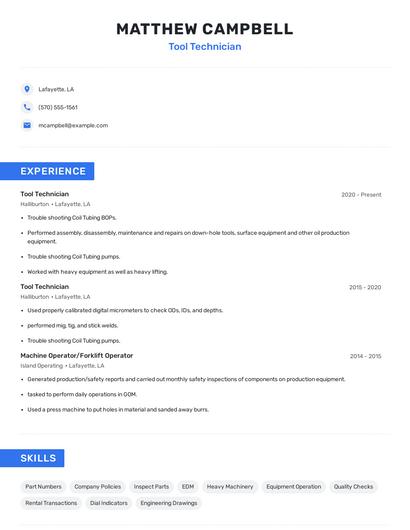

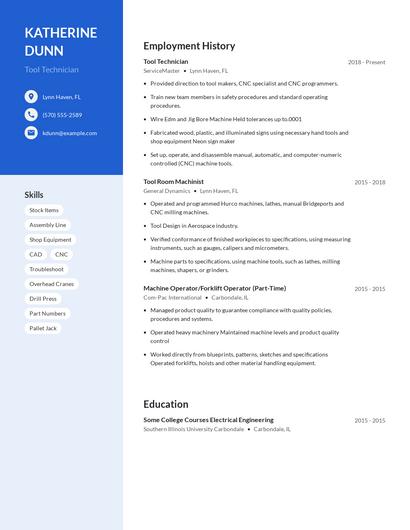

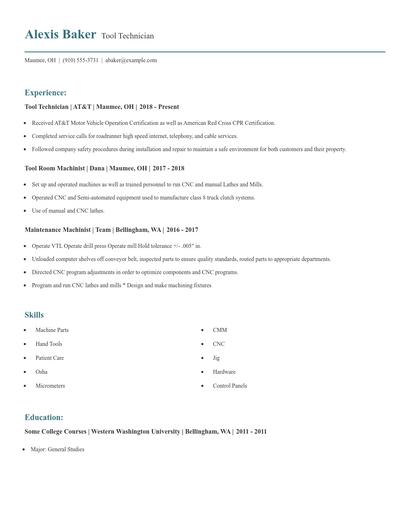

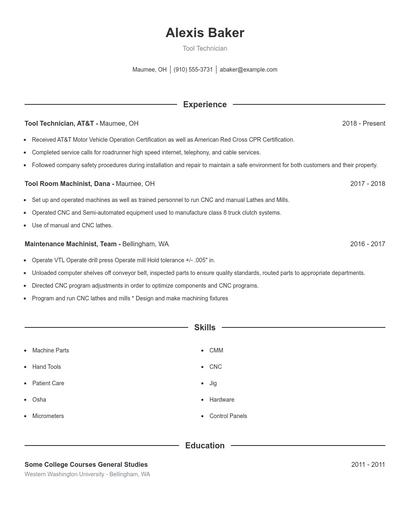

Here are examples of responsibilities from real tool technician resumes:

- Use specialize tools and machinery (CNC milling machine, manual lathe, manual milling machine and surface grinders . )

- Program and operate wire EDM machine, milling machines, drill presses, surface grinders, lathes and jig grinders.

- Perform mig, tig, and stick welds.

- Skil welder utilizing TIG, MIG and stick welding processes.

- Work on and troubleshoot the press machinery using calipers, micrometers and other precision tools.

- Learned to use a TIG welder . )

- Make basic prints using Solidworks.

- Adhere to ISO rules and regulations.

- Test and run finished machines for customer approval.

- Etch department - manufacturing of analog microchip devices.

- Prepare thorough diagnosis notes and work summaries for work orders.

- Close tolerance fabrication of prototype parts for miniature DC motors.

- Machine new parts or repair existing parts using manual mills and lathes, and CNC mill.

- Perform inventory control on all CNC tooling, fixtures, and electrical supplies used in the support of production operations.

- Use calipers, metric tools, and tape measures to record measurements.

Tool technician skills and personality traits

We calculated that 11% of Tool Technicians are proficient in Grinders, Hand Tools, and CNC. They’re also known for soft skills such as Analytical skills, Manual dexterity, and Math skills and computer application experience.

We break down the percentage of Tool Technicians that have these skills listed on their resume here:

- Grinders, 11%

Use of manual lathes, mills surface grinders, core grinders and various other tool making Machines.

- Hand Tools, 10%

Adjusted functional parts of devices and control instruments, using hand tools, levels, plumb bobs and straightedges.

- CNC, 9%

Performed inventory control on all CNC tooling, fixtures, and electrical supplies used in the support of production operations.

- Calipers, 7%

Worked on and troubleshoot the press machinery using calipers, micrometers and other precision tools.

- Micrometers, 6%

Gauged test results using various measuring tools including micrometers and microscopes.

- Jigs, 6%

Conceived and designed precision scanner target cutting jig - reduced cutting time, increased productivity, increased accuracy.

"grinders," "hand tools," and "cnc" are among the most common skills that tool technicians use at work. You can find even more tool technician responsibilities below, including:

Analytical skills. The most essential soft skill for a tool technician to carry out their responsibilities is analytical skills. This skill is important for the role because "machinists and tool and die makers must be able to interpret technical blueprints, models, and specifications so that they can craft precision tools and metal parts." Additionally, a tool technician resume shows how their duties depend on analytical skills: "analyze data from catia v5, right hemisphere and engineering drawings/sketches. "

Manual dexterity. Many tool technician duties rely on manual dexterity. "machinists’ and tool and die makers’ work demands accuracy, sometimes to within .0001 of an inch," so a tool technician will need this skill often in their role. This resume example is just one of many ways tool technician responsibilities rely on manual dexterity: "generate records digitally on computer and manually spreadsheets in excel for iso requirements. "

Technical skills. For certain tool technician responsibilities to be completed, the job requires competence in "technical skills." The day-to-day duties of a tool technician rely on this skill, as "machinists and tool and die makers must understand metalworking processes." For example, this snippet was taken directly from a resume about how this skill applies to what tool technicians do: "use of precision instruments such as micrometers, optical comparator multi-skill quality and technical operator. "

Mechanical skills. A commonly-found skill in tool technician job descriptions, "mechanical skills" is essential to what tool technicians do. Tool technician responsibilities rely on this skill because "machinists and tool and die makers may operate milling machines, lathes, grinders, laser and water jetting machines, wire electrical discharge machines, and other machine tools." You can also see how tool technician duties rely on mechanical skills in this resume example: "performed minor preventative and routine maintenance services to equipment, furnishings, fixtures, and pneumatic/electric/mechanical hand tools. "

The three companies that hire the most tool technicians are:

- Mac Tools1,271 tool technicians jobs

- Oil States International20 tool technicians jobs

- Novolex9 tool technicians jobs

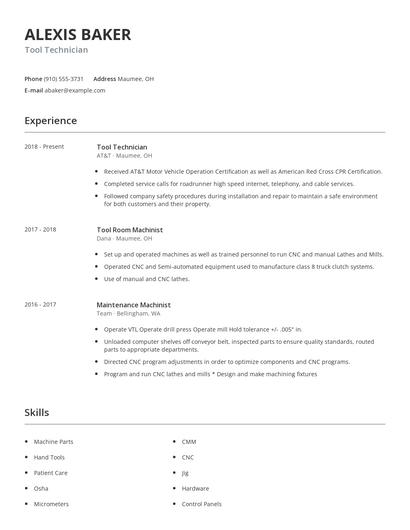

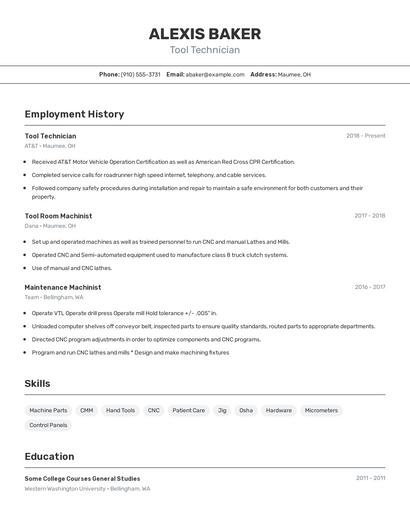

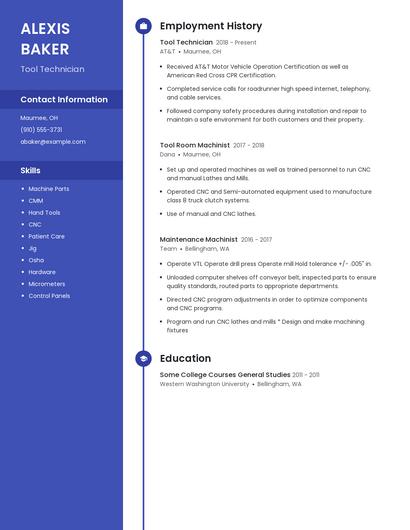

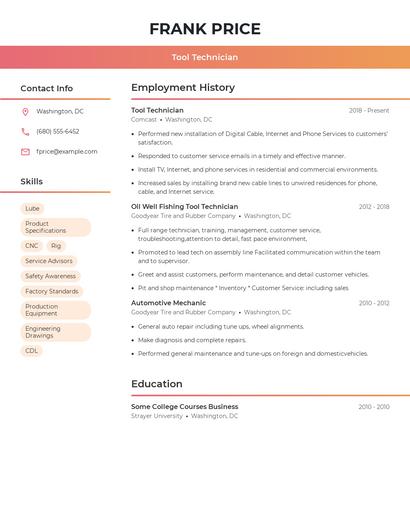

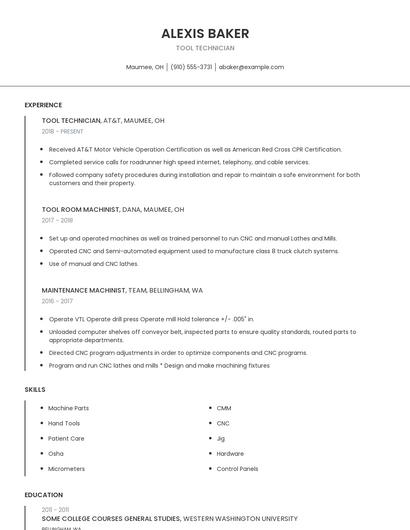

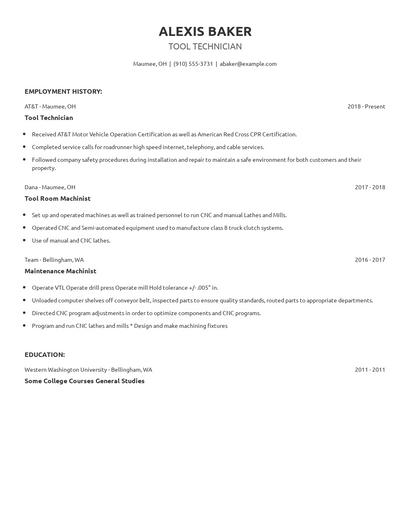

Choose from 10+ customizable tool technician resume templates

Build a professional tool technician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your tool technician resume.Compare different tool technicians

Tool technician vs. Grinder

Depending on the industry, a grinder has a diverse range of duties. Typically, they oversee setting up and operating bearing grinders, cam grinders, and CNC lathes. A grinder must meet with the manufacturer's specifications by making use of shop drawings. Additionally, they may be tasked with repairing any mechanical breakdowns on the machines.

These skill sets are where the common ground ends though. The responsibilities of a tool technician are more likely to require skills like "first hand," "micrometers," "preventive maintenance," and "machine tools." On the other hand, a job as a grinder requires skills like "grinding machines," "grinding wheels," "safety procedures," and "math." As you can see, what employees do in each career varies considerably.

Grinders really shine in the automotive industry with an average salary of $40,459. Comparatively, tool technicians tend to make the most money in the energy industry with an average salary of $64,215.grinders tend to reach similar levels of education than tool technicians. In fact, grinders are 1.3% less likely to graduate with a Master's Degree and 0.1% more likely to have a Doctoral Degree.Tool technician vs. Machine operator/machinist

A Maintenance Machinist is responsible for implementing and maintaining industrial machinery. Their primary duties include investigating and diagnosing equipment failures and performing corrective actions.

Each career also uses different skills, according to real tool technician resumes. While tool technician responsibilities can utilize skills like "hand tools," "first hand," "cnc," and "preventive maintenance," machine operators/machinist use skills like "cnc lathes," "math," "cnc machines," and "safety procedures."

Machine operators/machinist earn similar levels of education than tool technicians in general. They're 0.6% less likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.Tool technician vs. Maintenance machinist

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a tool technician is likely to be skilled in "first hand," "micrometers," "preventive maintenance," and "injection molds," while a typical maintenance machinist is skilled in "cranes," "math," "preventative maintenance," and "aluminum."

Maintenance machinists earn the best pay in the technology industry, where they command an average salary of $61,086. Tool technicians earn the highest pay from the energy industry, with an average salary of $64,215.Most maintenance machinists achieve a similar degree level compared to tool technicians. For example, they're 1.1% less likely to graduate with a Master's Degree, and 0.1% less likely to earn a Doctoral Degree.Tool technician vs. Machinist apprentice

Types of tool technician

Updated January 8, 2025