Automatically apply for jobs with Zippia

Upload your resume to get started.

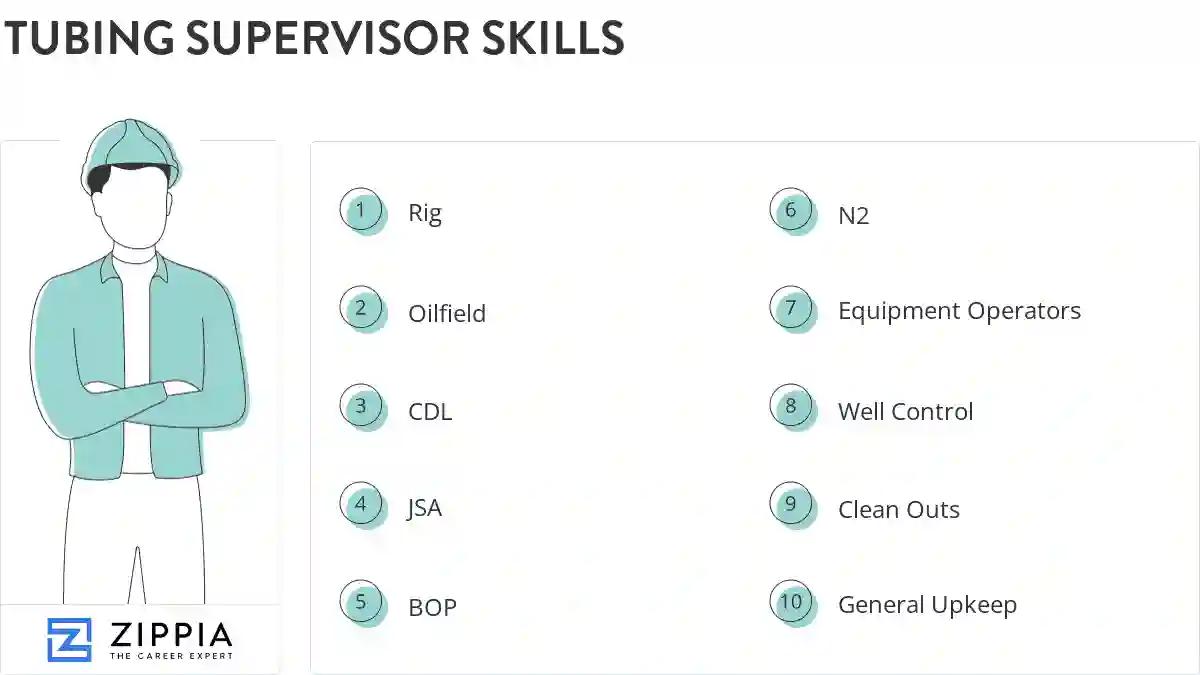

Tubing supervisor skills for your resume and career

15 tubing supervisor skills for your resume and career

1. Rig

Rigging includes designing, preparing, or setting up equipment for drilling operations. This skill is one of the main and most important activities in the oil and gas industry, whether it's for onboard operations or port operations. Rigging systems should have parts like master links, shackles, slings, and lifting bags for underwater lifting. Professionals working with rigging systems are responsible for tasks like operating platform lifts, forklifts, and overhead cranes.

- Coordinate operations directly with Company Representative, Coil Tubing Company and/or Work over Rig Representative.

- Rig up and running tools in and out of the borehole and related procedures associated with mill outs and fishing.

2. Oilfield

- Run crew doing oilfield interventions.

3. CDL

- Maintain a clean driving record and keep CDL current with all Federal requirements.

- Coil Tubing operator- Heavy equipment operator, CDL Driver.-Backhoe, trackhoe, dozer, heavy haul driver experience.

4. JSA

- Prepare JSA's & conduct daily Safety meetings.

- Do daily JSA and job tickets.

5. BOP

- Test/repaired trees as needed, rebuilt high pressure BOP's, hydraulics, injector heads.

- Monitor all bop testing on specific job locations.Class A CDLThru Tubing Fishing/Milling/Perforating experience-4 years

6. N2

- Certified, Coil Tubing, Fluid Pump, N2 Pump Operations, Crane Operater.

- Supervised N2 functions of foam frac, 45k-60kscfm.

Choose from 10+ customizable tubing supervisor resume templates

Build a professional tubing supervisor resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your tubing supervisor resume.7. Equipment Operators

- Assist in training or indirectly supervising entry level Equipment Operators.

- Directed and coordinated equipment operators' activities.

8. Well Control

- Prepared jobs working in normal, high pressure, blowouts and well control situations.

- Certified Crane Operator CPR Trained Certified in Well Control EDUCATION:.

9. Clean Outs

- Operate and maintain a fluid pump for oil well and down hole clean outs.

- Worked offshore for three years performing washes, N2 jetting, fishing and sand wash clean outs.

10. General Upkeep

General upkeep means keeping a place or property in a good state. One can do this by regularly checking on both its exteriors and interiors to prevent breakdowns and keep it looking its best.

- Performed maintenance and general upkeep of the coiled tubing units and related equipment.

11. TCP

- Perform field inspection of equipment prior to preparing equipment for a TCP job.

- Operated unit in relief of coil operator as needed performing all functions (TCP, Drilling, fishing)

12. Frac

- Coordinated crews and mixing plants and filtration, transfer pumps for coiled tubing and frac operations.

- Performed 2 millout operations following 8 stage frac.

13. Troubleshoot

Troubleshooting is the process of analyzing and fixing any kind of problem in a system or a machine. Troubleshooting is the detailed yet quick search in the system for the main source of an issue and solving it.

- Monitor, Troubleshoot, Evaluate and solve problems in a timely manner for Customer.

- Oversee coil and pump operators; troubleshoot onsite equipment malfunctions.

14. Equipment Maintenance

Equipment maintenance is any process that includes the use of maintenance methods and procedures to keep the organization's equipment in good and reliable working condition. This may include routine maintenance as well as corrective repairs. The practice takes place in a variety of settings, including catering establishments, industrial factories, manufacturing facilities, hotels, etc.

- Enforced and performed DOT compliance, equipment maintenance and employee training.

- Assist with other equipment maintenance while working at the the yard.Experience

15. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Maintained and ran a coil unit, pump, nitrogen pump.

- Travel to and from many different areas of Texas & South Eastern New Mexico Complete Knowledge of all tools ran.

5 Tubing Supervisor resume examples

Build a professional tubing supervisor resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your tubing supervisor resume.

What skills help Tubing Supervisors find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of tubing supervisor skills to add to your resume

The most important skills for a tubing supervisor resume and required skills for a tubing supervisor to have include:

- Rig

- Oilfield

- CDL

- JSA

- BOP

- N2

- Equipment Operators

- Well Control

- Clean Outs

- General Upkeep

- TCP

- Frac

- Troubleshoot

- Equipment Maintenance

- RAN

- Safety Procedures

- Safety Rules

- Customer Relations

- Equipment Inspections

- BHA

- H2S

- NCCCO

- General Maintenance

- HSE

Updated January 8, 2025