What does a warehouse assembler do?

A warehouse assembler takes on several responsibilities. They are responsible for preparing work that needs to be accomplished by studying and following assembly instructions to put together parts. They also interpret engineering blueprints and technical jargon. They are expected to verify accurate quantities of components and to check that the items are completed to ensure quality. They manage the inventory of parts and tools that are used in the process of assembly.

Warehouse assembler responsibilities

Here are examples of responsibilities from real warehouse assembler resumes:

- Operate heavy equipment such as, forklifts (stand up and sit down) and electric pallets jacks.

- Solder PC board and finish components by following blueprints and assembly specifications.

- Develop processes and documentation consistent with ISO requirements for assembling new products.

- Align units using jigs and fixtures also inspecting complete components to ensure satisfaction.

- Excel in interpreting detail aligning units using jigs and fixtures, and inspecting complete components to ensure conformance to specifications.

- Operate power equipment including: order pickers, tuggers, reach trucks, and counterbalance forklifts.

Warehouse assembler skills and personality traits

We calculated that 33% of Warehouse Assemblers are proficient in Basic Math, Hand Tools, and Assembly Line. They’re also known for soft skills such as Mechanical skills, Visual ability, and Hand-eye coordination.

We break down the percentage of Warehouse Assemblers that have these skills listed on their resume here:

- Basic Math, 33%

Warehouse maintenance as needed Skills Used *Determination *Consistency *Literary skills *Basic Mathematics

- Hand Tools, 9%

Install ground clamps on to the electrical wire with a screw gun and hand tools.

- Assembly Line, 9%

Worked assembly line to make furnace filters accurately and efficiently.

- Pallets, 8%

Prepared orders by unpacking material, packing boxes and placing completed orders onto pallets.

- Part Numbers, 8%

Distribute automotive parts to proper areas while ensuring accurate part numbers are associated with specified location numbers.

- Pallet Jack, 4%

Delivered and routed materials to departments, using work devices, such as forklift, pallet jack, hand trucks.

Common skills that a warehouse assembler uses to do their job include "basic math," "hand tools," and "assembly line." You can find details on the most important warehouse assembler responsibilities below.

Mechanical skills. The most essential soft skill for a warehouse assembler to carry out their responsibilities is mechanical skills. This skill is important for the role because "material moving machine operators make minor adjustments to their machines and perform basic maintenance on them." Additionally, a warehouse assembler resume shows how their duties depend on mechanical skills: "performed electrical/mechanical assembly/cnc and component id/smt/solder/kitting/packaging/qc/qa/order fulfillment/cycle counts. "

Visual ability. Another essential skill to perform warehouse assembler duties is visual ability. Warehouse assemblers responsibilities require that "material moving machine operators must be able to see clearly where they are driving or what they are moving." Warehouse assemblers also use visual ability in their role according to a real resume snippet: "designed, developed, and maintained an excel-visual basic for application inventory system to manage bonded goods. "

The three companies that hire the most warehouse assemblers are:

- Nexus Staffing Solutions131 warehouse assemblers jobs

- Kelly Services11 warehouse assemblers jobs

- Staff Management11 warehouse assemblers jobs

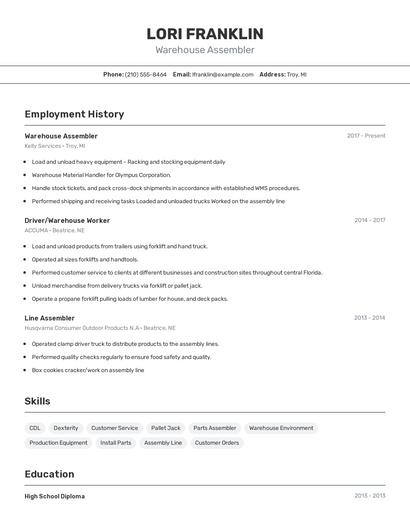

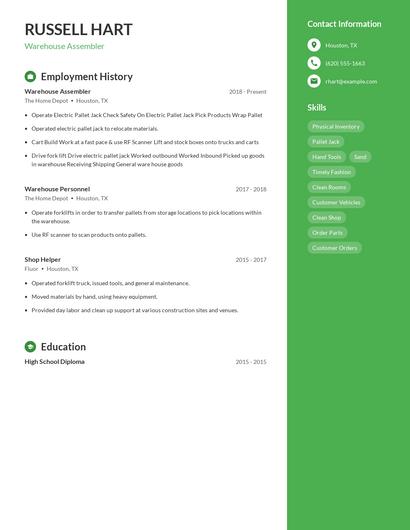

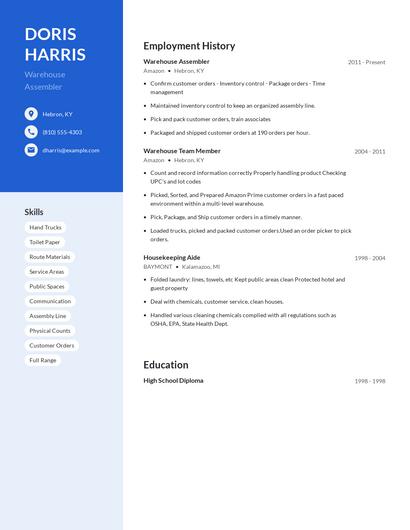

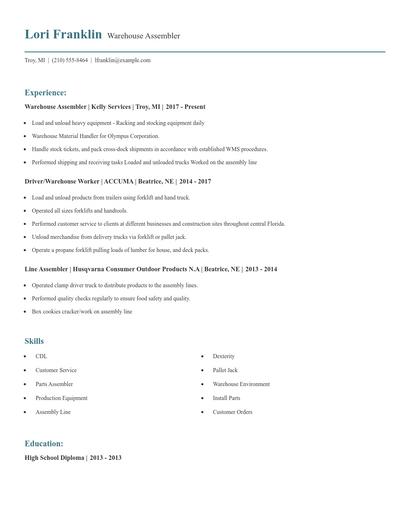

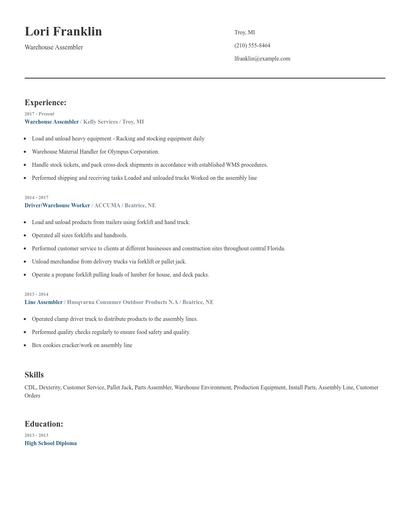

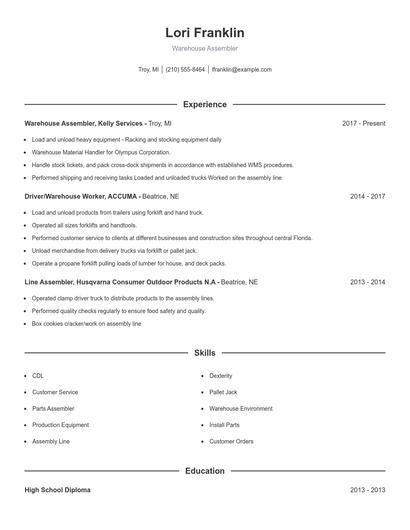

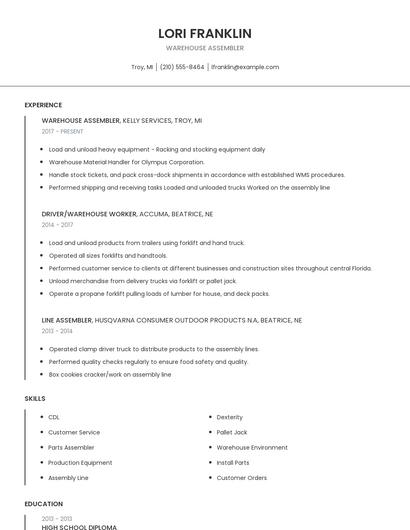

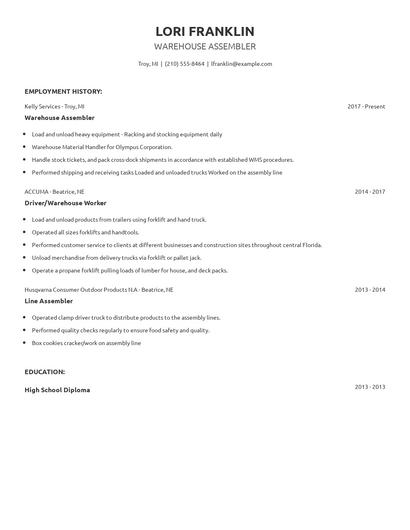

Choose from 10+ customizable warehouse assembler resume templates

Build a professional warehouse assembler resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your warehouse assembler resume.Compare different warehouse assemblers

Warehouse assembler vs. Assembler/material handler

A warehouse material handler is responsible for assisting warehouse operations, moving merchandise from one place to another, labeling products, performing quality check procedures, packaging goods, and loading and unloading items from distribution vehicles. Warehouse material handlers operate warehouse tools and equipment for production, as well as ensuring the adequacy of stock inventory needed for orders and deliveries. A warehouse material handler also updates product information on the database and do administrative tasks, such as writing reports and responding to customers' inquiries and concerns.

These skill sets are where the common ground ends though. The responsibilities of a warehouse assembler are more likely to require skills like "basic math," "hand tools," "assembly line," and "pallets." On the other hand, a job as an assembler/material handler requires skills like "line assembly," "safety procedures," "electric pallet jack," and "safety rules." As you can see, what employees do in each career varies considerably.

Assembler/material handlers earn the highest salaries when working in the automotive industry, with an average yearly salary of $36,778. On the other hand, warehouse assemblers are paid more in the manufacturing industry with an average salary of $31,847.The education levels that assembler/material handlers earn slightly differ from warehouse assemblers. In particular, assembler/material handlers are 0.6% more likely to graduate with a Master's Degree than a warehouse assembler. Additionally, they're 0.1% more likely to earn a Doctoral Degree.Warehouse assembler vs. Material handler/warehouse

In the manufacturing industry, an assembler/packer is primarily responsible for assembling components and packing products according to guidelines and protocols. They are responsible for understanding assembly instructions and schematics, operating tools and equipment, and developing safe and efficient strategies to accomplish production goals according to schedules. There are also times when they must attend meetings, produce progress reports, perform maintenance checks on machines, and clean work areas. Moreover, as an assembler/packer, it is essential to adhere to the facility's safety standards and policies for a safe and effective workflow.

In addition to the difference in salary, there are some other key differences worth noting. For example, warehouse assembler responsibilities are more likely to require skills like "part numbers," "pallet jack," "production process," and "clean rooms." Meanwhile, a material handler/warehouse has duties that require skills in areas such as "work ethic," "supply support," "ladders," and "customer service." These differences highlight just how different the day-to-day in each role looks.

Material handler/warehouses earn a higher average salary than warehouse assemblers. But material handler/warehouses earn the highest pay in the manufacturing industry, with an average salary of $34,722. Additionally, warehouse assemblers earn the highest salaries in the manufacturing with average pay of $31,847 annually.material handler/warehouses earn similar levels of education than warehouse assemblers in general. They're 0.7% more likely to graduate with a Master's Degree and 0.1% more likely to earn a Doctoral Degree.Warehouse assembler vs. Assembler/packer

A general warehouse worker takes responsibility for doing various duties in warehousing. General warehouse workers receive and process incoming materials and stock, pick and file orders, and pack and ship these orders. The workers manage, organize, and retrieve stocks from the warehouse. They make sure that the orders are picked up and/or delivered on time. It is expected from them to have working experience in the job. They have to be proficient in terms of inventory software, systems, and databases. Among the other necessary skills for this career are time management, analytical, communication, and good organizational skills.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from warehouse assembler resumes include skills like "basic math," "pallets," "warehouse environment," and "hand trucks," whereas an assembler/packer is more likely to list skills in "defective products," "safety procedures," "safety policies," and "inspect containers. "

Assembler/packers earn the highest salary when working in the manufacturing industry, where they receive an average salary of $30,029. Comparatively, warehouse assemblers have the highest earning potential in the manufacturing industry, with an average salary of $31,847.When it comes to education, assembler/packers tend to earn similar degree levels compared to warehouse assemblers. In fact, they're 0.5% more likely to earn a Master's Degree, and 0.0% more likely to graduate with a Doctoral Degree.Warehouse assembler vs. General warehouse worker

Types of warehouse assembler

Updated January 8, 2025