Automatically apply for jobs with Zippia

Upload your resume to get started.

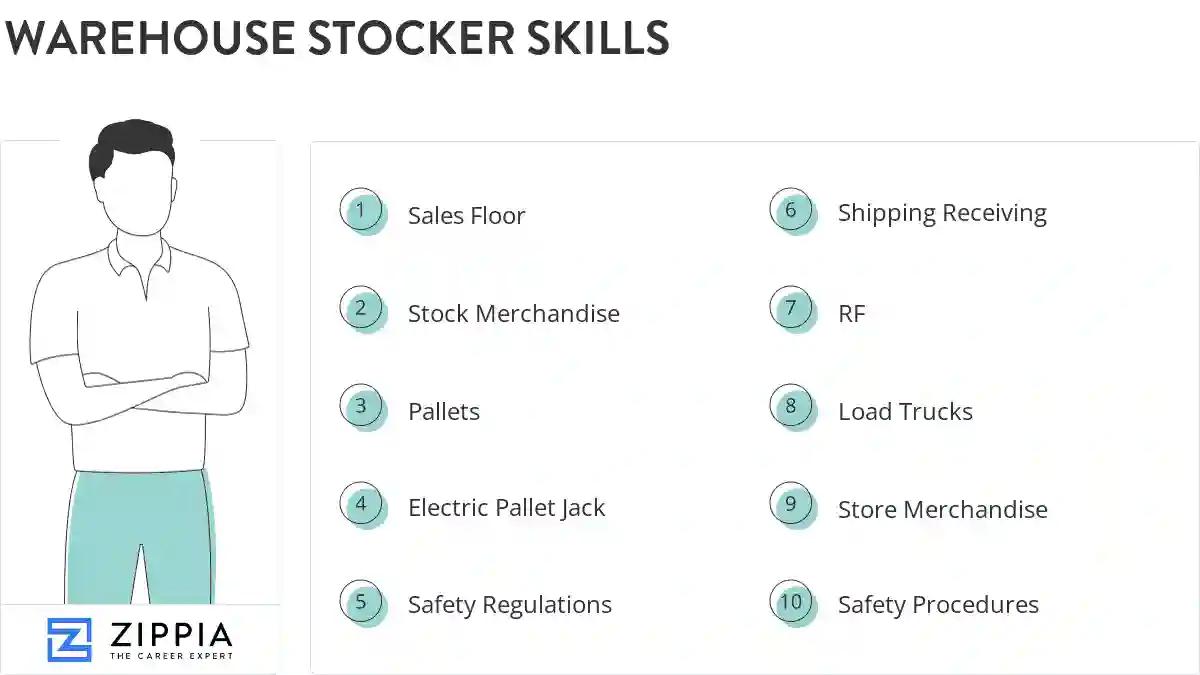

Warehouse stocker skills for your resume and career

15 warehouse stocker skills for your resume and career

1. Sales Floor

The sales floor is the area in a company or a business that is specified for retail activities or is designated as the selling area of the shop. A car showroom can be considered a sales floor, as it has cars in its display which are to be sold. A sales floor is generally crowded with sales assistants who are there to help you out while you can search and check out the products. Generally a sales floor has free access to the public and they can observe, view and get information about the product that is being sold.

- Warehouse (shipping and receiving), forklift operator, loading and unloading merchandise, delivering merchandise to the sales floor.

- Moved inventory throughout the store, including: sales floor; receiving; register areas and lawn and garden.

2. Stock Merchandise

- Unload the trucks stock merchandise, on the floor work in the warehouse and get the customer there merchandise

- Operate a Forklift to stock merchandise as needed.

3. Pallets

- Clean and organize warehouse, unload stock trucks, break down pallets, Stock goods in store and cashier when needed.

- Operate single/double pallet jacks, Crown reach lifts, and forklift, make sure Allocations are filled for the order selectors.

4. Electric Pallet Jack

- Operated forklifts, order pickers, electric pallet jacks to put away new stock, and also pull orders for customers.

- Use of box cutters, ladders, scanning gun, operating forklift and use of electric pallet jack

5. Safety Regulations

- Cleaned and maintained supplies, tools, equipment and storage areas in order to ensure compliance with safety regulations.

- Experienced in line assembly, complying with all job safety regulations, and keeping warehouse cleaned and organized.

6. Shipping Receiving

- Operated various types of forklifts, pulled orders, light shipping receiving using UPS and Fed Ex shipping software.

- Worked in shipping receiving in charge of packaging labeling and loading unloading product.

Choose from 10+ customizable warehouse stocker resume templates

Build a professional warehouse stocker resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your warehouse stocker resume.7. RF

- Use RF scanner to scan boxes to be returned to their right location.

- Use of RF scanner to record and relocate inventory items in stock.

8. Load Trucks

- Stock seed products, run purifying machines, load trucks for shipping and receiving and supervise temp workers.

- Worked with team members to unload and load trucks and put stock away with other warehouse teammates.

9. Store Merchandise

- Conducted monthly audits of store merchandise, decreasing the occurrence of lost/misplaced items aiding the Loss Prevention team.

- Unloaded store merchandise from trucks, kept track of items, and stored them.

10. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Followed proper safety procedures while using the pallet jack and trash compactor.

- Understand the safety procedures for loading and unloading a truck.

11. Delivery Truck

- Stocked warehouse with new inventory* Loaded merchandise from warehouse to delivery truck* Made deliveries to customers

- Utilize power equipment to unload delivery trucks (concrete, soil, compost, etc.)

12. Safety Rules

Principles or regulations that ensure the protection of people, objects, or the environment are called safety rules. These rules can be governing actions, devices, or procedures that help in minimizing the risks of loss, injury, or damage.

- Worked within the guidelines of safety rules and regulations.

- Learned and followed safety rules and guidelines.

13. Hand Trucks

Hand trucks are also known as a dolly or a two wheeler is an L-shaped, box moving, handcart. The hand truck has two big wheels on one side of the base and has a small ledge that holds the object to be moved. The hand truck is operated manually and has a handle that a person can use to load the boxes into the base and then unload it. It balances the weight of the objects and makes carrying heavy boxes easier.

- Experience with operating a baler, pallet jack, ladders, multiple hand & power tools, dollies & hand trucks.

- Cleaned and maintained the warehouse in compliance with OSHA safety standards Unloaded cargo from truck with hand trucks and pallet jacks.

14. Customer Orders

- Demonstrated ability to organize products according to specific customer orders.

- Stocked warehouse shelves; inventoried merchandise; processed and filled customer orders for packing and shipment.

15. Stock Shelves

To "stock shelves" is referred as the process of putting the supplies on the shelves in the store. It is important to stock the shelves timely as empty shelves can cost a business too much.

- Load and unload merchandise, sort and stack then transport to floor and stock shelves.

- Prepare products ordered by stores, deliver products to Receiving department, stock shelves.

5 Warehouse Stocker resume examples

Build a professional warehouse stocker resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your warehouse stocker resume.

What skills help Warehouse Stockers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of warehouse stocker skills to add to your resume

The most important skills for a warehouse stocker resume and required skills for a warehouse stocker to have include:

- Sales Floor

- Stock Merchandise

- Pallets

- Electric Pallet Jack

- Safety Regulations

- Shipping Receiving

- RF

- Load Trucks

- Store Merchandise

- Safety Procedures

- Delivery Truck

- Safety Rules

- Hand Trucks

- Customer Orders

- Stock Shelves

- Safety Standards

- Filling Orders

- Physical Counts

- Electric Marking Tools

- Identification Tags

- Purchase Orders

- Assembly Line

- Stock Location Orders

- Stock Warehouse

- Dollies

- Orderly Fashion

- Store Shelves

- Clean Warehouse

- Physical Capabilities

- Stock Room

- Quality Service

- Inventory Computations

- Inventory Control Codes

- Workstations Neat

- Manual Pallet Jack

- Groceries

- Warehouse Shelves

- Taking Inventory

- Display Cases

Updated January 8, 2025