Automatically apply for jobs with Zippia

Upload your resume to get started.

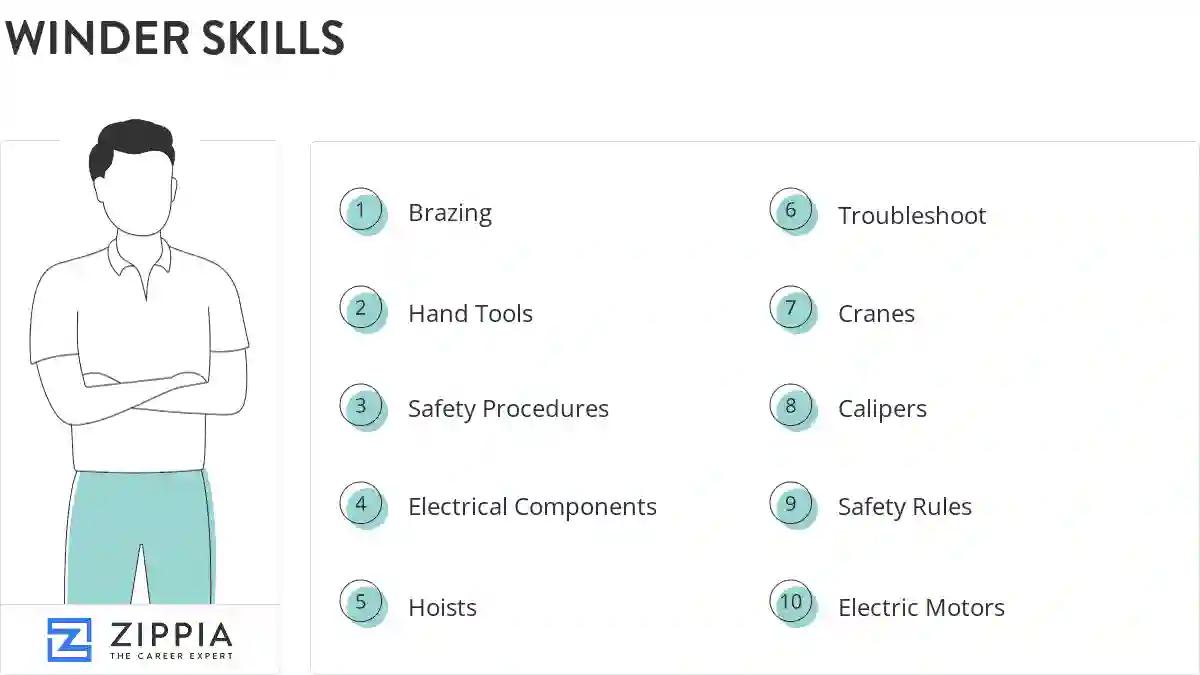

Winder skills for your resume and career

15 winder skills for your resume and career

1. Brazing

- Certified in overhead crane and propane forklift operation Certified in copper and silver acetylene brazing.

- Set up and operate thermal brazing machine by reading work orders, blueprints, and data charts.

2. Hand Tools

- Attached, altered, and trimmed materials such as wire, insulation, and coils, using hand tools.

- Disassemble and assemble motors, and repair and maintain electrical components and machinery parts, using hand tools.

3. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Observe all safety procedures and policies and use proper protective equipment.

- Adhere to all compliance and safety procedures in the workplace.

4. Electrical Components

- Tested and assembled electrical components and wires for gas detection monitors.

- Examined and tested wired electrical components, using measuring devices.

5. Hoists

- Maintain production machines and other various equipment (including winders, hoists, trim puller, mixers).

- Lift raw materials, finished products, and packed items, manually or using hoists.

6. Troubleshoot

Troubleshooting is the process of analyzing and fixing any kind of problem in a system or a machine. Troubleshooting is the detailed yet quick search in the system for the main source of an issue and solving it.

- Tear down, inspect, and troubleshoot problem motors.

Choose from 10+ customizable winder resume templates

Build a professional winder resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your winder resume.7. Cranes

- Handled overhead 5-ton crane to move magnets

- worked on the production line, Loading Parent rolls of Paper into Winder which would feed the machine Used hoist Cranes.

8. Calipers

- Used micrometers and calipers to measure, also used a turn to turn counter to count turns on coils.

- Used tools such as calipers, saws, welders and overhead crane to assist in producing coils.

9. Safety Rules

Principles or regulations that ensure the protection of people, objects, or the environment are called safety rules. These rules can be governing actions, devices, or procedures that help in minimizing the risks of loss, injury, or damage.

- Operate Crown forklifts, reach trucks, winders and stock pickers* Follow safety rules and regulations

- Followed all safety rules required by OSHA while operating in twelve hour shifts.

10. Electric Motors

- Burned, stripped and took data relative to electric motors.

- Burned, stripped and took data off of electric motors.

11. Production Process

The production process is a series of events and industrial activities that come into play when raw material are delivered onto the production facility for manufacturing. The process involves different steps of production from start to finish such as; research, design formation, design testing, product manufacturing, and assembly according to the design, product experimentations, and supply.

- Perform proper scanning procedures during production process.

- Prepared machine for production process.

12. Armatures

- Wind armatures by diagrams to meet manufactures specifications.

- Form and mush wound armatures, using an epoxy resin VPI system for impregnation.

13. Electrical Equipment

- Coordinated projects for and collected data on electrical equipment.

- Worked directly with engineers in order to create mock-ups and prototypes to give our customers the best quality electrical equipment possible.

14. Fork Trucks

- Operate: Sand Blaster, Steam Jenny, 10-75 Ton Crane & Fork Trucks.

15. Ac

AC (Alternating Current) is the electric current that periodically changes its polarity and magnitude. Most devices, which are connected to the electrical grid directly, operate on AC. Electrical outlets in commercial areas and homes also supply electrical current.

AC may also refer to Air Conditioning as it relates to working to install duct work and air conditing units as part of an HVAC system.

- Repair and rebuild AC and DC Electrical Motors.

- Take data, wind, and connect Large AC and DC Motors.

5 Winder resume examples

Build a professional winder resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your winder resume.

What skills help Winders find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of winder skills to add to your resume

The most important skills for a winder resume and required skills for a winder to have include:

- Brazing

- Hand Tools

- Safety Procedures

- Electrical Components

- Hoists

- Troubleshoot

- Cranes

- Calipers

- Safety Rules

- Electric Motors

- Production Process

- Armatures

- Electrical Equipment

- Fork Trucks

- Ac

- Dc

- Engineering Blueprints

- Electrical Tests

- Assembly Line

- VPI

- TIG

- CNC

- Customer Specs

- Spindles

- Safety Regulations

- Power Transformers

- Detect Defects

- Asbestos

- Resistors

Updated January 8, 2025