Automatically apply for jobs with Zippia

Upload your resume to get started.

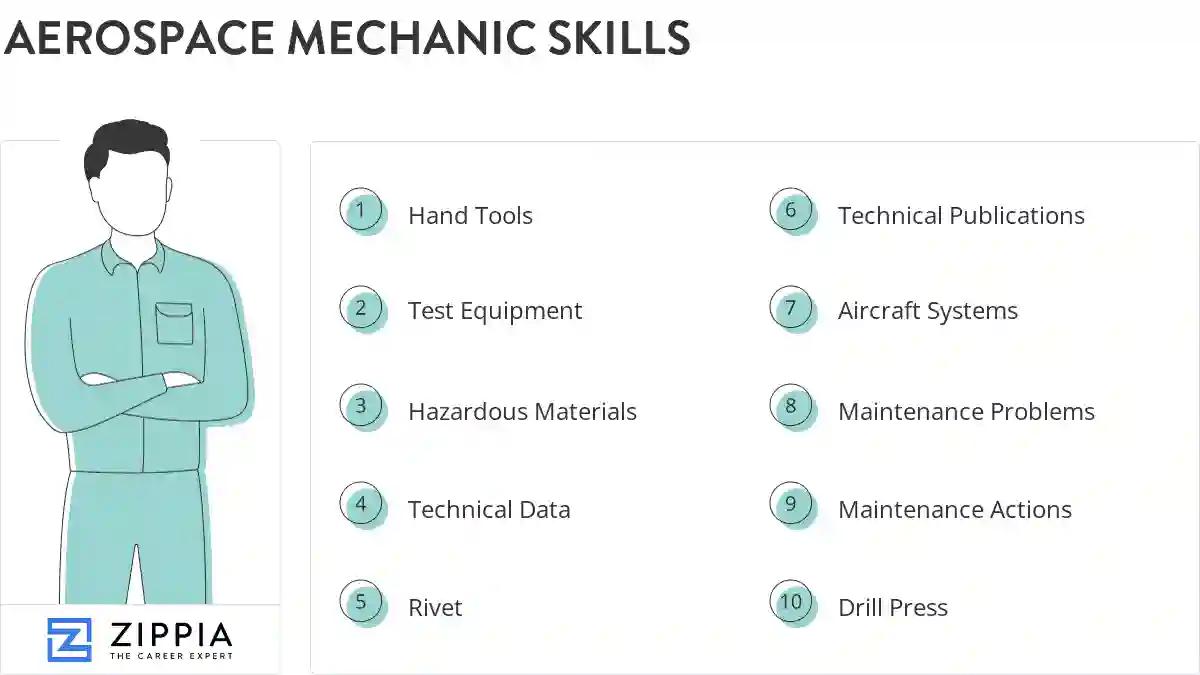

Aerospace mechanic skills for your resume and career

15 aerospace mechanic skills for your resume and career

1. Hand Tools

- Dismantled and reassembled products using calipers to calibrate shims and other hand tools for assembly.

- Assembled aircraft, using layout tools, hand tools, power tools, rivets, clamps, jigs.

2. Test Equipment

Test equipment is a mechanical tool or a device which is used create signals and gather response from an electronic device under test. It helps in detecting any faults in the device and it also proves the proper operation of the electronic device.

- Diagnose faults or malfunctions to determine required repairs, using engine diagnostic equipment such as computerized test equipment and calibration devices.

- Set up, operated and tested hydraulic equipment under simulated or actual operation utilizing ground test equipment as required.

3. Hazardous Materials

Any substance or good that is harmful to human health as well as the environment are called hazardous materials. Such materials must be handled carefully to avoid any mishaps. Harmful gases. chemicals, strong medicines or drugs, radioactive elements required for radiation purposes, a human blood sample that carries germs, all of these are considered hazardous materials.

- Inspected outgoing packages to ensure hazardous materials/dangerous goods were transported safely and in compliance with International Air Dangerous Good Regulations.

- Validated government compliance of 72 hazardous materials to achieve zero organizational discrepancies during federal inspection.

4. Technical Data

Technical data refers to both scientific and technical nature and information recorded and presented in any form other than financial and management information but includes manuals and instructional materials, as well as technical data formatted as a computer database.

- Maintain bench stock and order parts using technical data and company procedures.

- Used technical data, layout drawings, schematics and pictorial diagrams to troubleshoot/repair engine malfunctions.

5. Rivet

- Used rivet guns, squeeze, bucking bars, drills 500rpm-5500, 45 degree-double 90degree.

- Used rivet tools including compression riveters, metal bucking bars, recoilless, rivet hammers.

6. Technical Publications

- Utilized technical publications or automated systems in maintaining vehicles to prescribed manufactures maintenance schedules and for researching parts.

- Assembled repairs using special fasteners and adhesives, check repairs for serviceability according to specifications and technical publications.

Choose from 10+ customizable aerospace mechanic resume templates

Build a professional aerospace mechanic resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your aerospace mechanic resume.7. Aircraft Systems

Aircraft systems refer to the subsystems necessary for the efficient and safe operation of an aircraft, including flight controls, landing gear, electrical systems, hydraulics, avionics, navigation, communications, and instrumentation. All aircraft require essential systems such as engine, propeller, induction, ignition systems, as well as fuel, lubrication, cooling, electrical, landing gear, and environmental control systems to aid flight. Understanding aircraft systems in flight is essential for safe operation and proper maintenance.

- Adjusted, aligned, rigged, and calibrated aircraft systems and instruments.

- Performed systems readiness tests on aircraft systems under simulated operational conditions.

8. Maintenance Problems

- Diagnosed and repaired maintenance problems through engineering and troubleshooting.

- Report maintenance problems occurring at project site to supervisor and negotiate changes to resolve system conflicts.

9. Maintenance Actions

- Plan maintenance actions and coordinate support.

- Qualified: Became a collateral duty inspector, inspected and supervised maintenance actions to ensure quality and safety of maintenance performed.

10. Drill Press

A drill press refers to a device used to produce holes in hard substances. When drilling the holes, you need to clamp the workpiece on a table and hold the drill in a rotating spindle and feed it into the workpiece.

- Operated hand and floor mounted power tools such as hand drills, band saw, drill press and disk sanders.

- Operated brake press, punch press, bladder press, drill press, bandsaws, grinders, and polishers.

11. Maintenance Procedures

A maintenance procedure refers to a thorough list of steps that details the way a maintenance task needs to be performed. It also acts as a documented standard that should be maintained when performing the task or job.

- Co-created and implemented additional maintenance procedures to routinely clean acceleration bleed valve screens.

- Interpreted and advised on maintenance procedures and policies to repair aircraft as part of a maintenance team.

12. Aircraft Maintenance

- Managed a five seasoned-mechanic team in the daily performance of duties pertaining to jet engine and aircraft maintenance.

- Manage administrative functions including comprehensive documentation of all aircraft maintenance records and inventory of aircraft equipment.

13. Unscheduled Maintenance

- Perform scheduled and unscheduled maintenance on 18 assigned C-5 B/C-model aircraft valued at over $3.7B.

- Work is performed in conjunction with scheduled and unscheduled maintenance on all aircraft systems to ensure reliability, acceptability and airworthiness.

14. Jigs

- Can operate hydraulic testing gear not pertaining but not limited to jigs such as HCT-10, T-10.

- Manufacture jigs, fixtures, forms, and molds.

15. Troubleshoot

Troubleshooting is the process of analyzing and fixing any kind of problem in a system or a machine. Troubleshooting is the detailed yet quick search in the system for the main source of an issue and solving it.

- Utilized testing equipment to inspect, analyze, and troubleshoot F-15 C/D aircraft.

- Repaired aircraft propellers and quick engine change kits Operated hydraulic propeller tester to troubleshoot and diagnose needed repairs

5 Aerospace Mechanic resume examples

Build a professional aerospace mechanic resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your aerospace mechanic resume.

What skills help Aerospace Mechanics find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of aerospace mechanic skills to add to your resume

The most important skills for an aerospace mechanic resume and required skills for an aerospace mechanic to have include:

- Hand Tools

- Test Equipment

- Hazardous Materials

- Technical Data

- Rivet

- Technical Publications

- Aircraft Systems

- Maintenance Problems

- Maintenance Actions

- Drill Press

- Maintenance Procedures

- Aircraft Maintenance

- Unscheduled Maintenance

- Jigs

- Troubleshoot

- Maintenance Forms

- Repair Aircraft

- Due Dates

- Landing Gear

- Test Runs

- Maintenance Functions

- Hazardous Waste

- Aircraft Structures

- Assembly Line

- Security Clearance

- FAA

- Safety Procedures

Updated January 8, 2025