Automatically apply for jobs with Zippia

Upload your resume to get started.

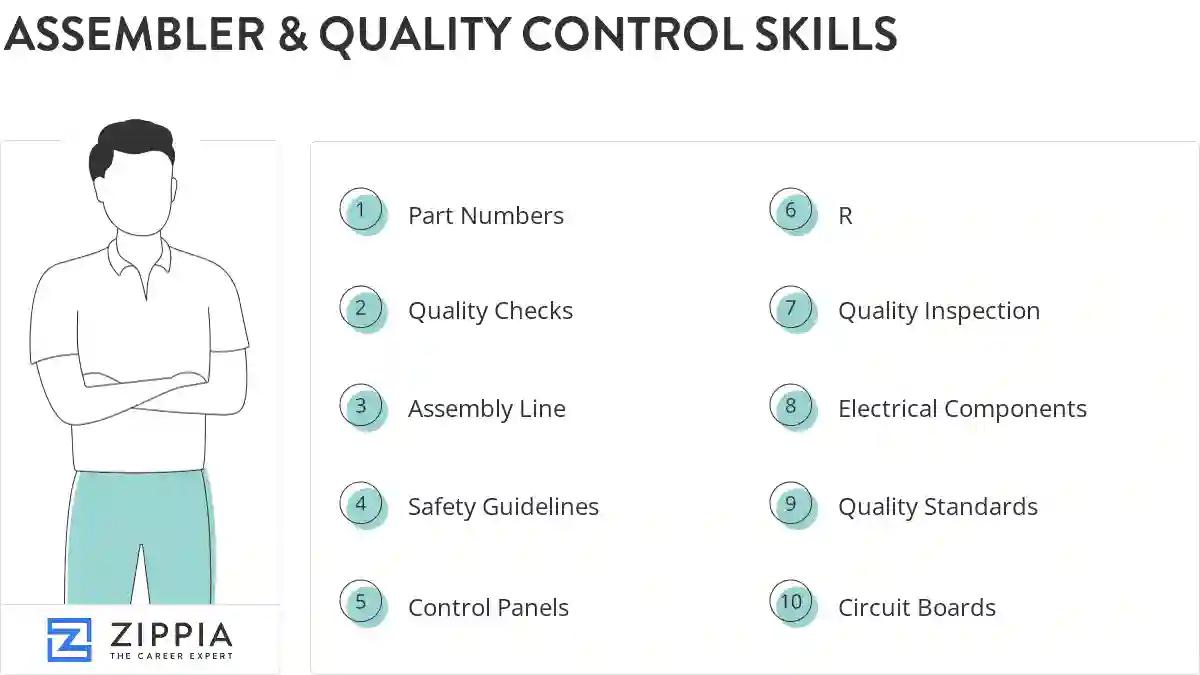

Assembler & quality control skills for your resume and career

15 assembler & quality control skills for your resume and career

1. Part Numbers

Part Numbers are special sets and strings of numbers used to identify and label parts. There is no one specific kind or set of parts for which this is used and the term can be found in various industries and used for various parts. Most often, a part number is only used to refer to one part and product within one company or organization. Part numbers, also, tend to inadvertently describe the item's purposes and physical features, too, through an organized code of sorts.

- Order parts and assign part numbers to new inventory as required.

- Compared part numbers to those on computer screen to determine if parts were correct and materials conformed to acceptable tolerances.

2. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Prepared daily quality check reports to supervisors and provide monthly quality control analysis.

- Assembled air vents for various auto companies and quality checked assembled parts for defects.

3. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Performed labor along an assembly line building automotive parts, verifying component accuracy and providing accurate component placement against blueprints.

- Maintain a report of unacceptable product to be reevaluated and fixed to an acceptable product by the assembly line.

4. Safety Guidelines

Safety guidelines are regulations or rules governing procedures, actions, or devices with the aim of reducing the occurrence or risk of loss, injury, and danger to properties, individuals, or the environment. To adhere to the safety guidelines and be able to make the best possible decisions to ensure everyone at the workplace is safe, you should possess a wide range of skills.

- Inspected finished products to ensure meeting the company and federal quality & safety guidelines.

- Followed safety guidelines and met all goals.

5. Control Panels

A control panel is a flat, enclosed unit, often the vertical part of a system in which the control or monitoring instruments are displayed and accessible to users. Control panels are typically closed-circuit boards with connections to all peripheral devices in their area. They can be found in factories to monitor and control machines or production lines and in places like nuclear power plants, ships, airplanes, and mainframe computers.

- Assembled and wired electrical control panels and explosion proof enclosures to customer's schematics Worked from schematics and customer's wiring diagrams

- Based on them, build/wire control panels Accomplishments My last project was building a PLC control panel for GE.

6. R

R is a free software environment and a language used by programmers for statistical computing. The R programming language is famously used for data analysis by data scientists.

- Assisted with R and D projects, developed jig process, troubleshooting.

- Helped implement and maintain QC program to obtain and keep our U and R stamps for the Wichita facility.

Choose from 10+ customizable assembler & quality control resume templates

Build a professional assembler & quality control resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your assembler & quality control resume.7. Quality Inspection

Quality inspections are measures to verify, examine or test various properties of one or more products and relate the results to the requirements to confirm compliance with the manufacturing processes. This is carried out to discover product defects and inform the management team for a decision on whether to approve or reject the product release.

- Scheduled daily production meetings and quality inspections.

- Performed quality inspections to finalized products.

8. Electrical Components

- Assembled and soldered car electrical components using hand solderer or a solder robot in an assembly cell group.

- Use of electrical components ex, test boards for touchscreens Solve problems quickly Customer Service Quality consistent work

9. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Trained and supervised new employees to follow engineering drawing specifications and quality standards.

- Ensured products manufactured met certain quality standards.

10. Circuit Boards

A circuit board refers to an electronic device used to offer mechanical support and connect components electrically using signal traces and conductive pathways.

- Assemble printed circuit boards, and electronic assemblies from documentation following quality specifications, while utilizing various tools and equipment.

- Manufacture construction, mining and agricultural equipment, electrical/air and electrical/hydraulics with circuit boards.

11. Tape Measure

A tape measure is a thin, flexible strip of plastic or metal that can be rolled up when it is not being used. The tape measure has numbers marked on it linearly which is used for measuring length.

- Use calipers,micrometers,height gauges,protractors and tape measure.

- Put awnings together worked about 72 hours a week it was a temporary job worked with drills tape measures hammers and etc

12. Soldering Irons

- Use of soldering irons and soldering.

- Heat soldering irons to specified temperatures for soldering.

13. ISO

- Preformed, installed and soldered parts per blueprint specifications* Quality Control Inspector* ISO certified* Certified to IPC-A-610 standards.

- Maintain proper paperwork, adhere to GMP, ISO 9001, and EHS standard operating procedures.

14. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Preformed inspection and processing focusing on precision CNC machining product.

- Performed inspection of incoming material, in-process, and final quality audits for the CNC manufactured line of engine cylinder sleeves.

15. QA

QA, or Quality Assurance is a procedure that entails all of the steps taken to avoid any errors in the manufacturing process or in the production of the goods that a company produces. It can also include ensuring the consistency of the services rendered. Quality assurance ensures that the quality of the service delivered to consumers meets or exceeds the promised expectations. This greatly aids in the prevention of any complications that might arise after the goods or services have been distributed. It makes sure that customers are satisfied.

- Assist with revising QA related SOPs, device investigations and NCR investigations.

- Assembled military cables Inspected all work done on cables (QA) tested tension and continuity

5 Assembler & Quality Control resume examples

Build a professional assembler & quality control resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your assembler & quality control resume.

What skills help Assemblers & Quality Control find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of assembler & quality control skills to add to your resume

The most important skills for an assembler & quality control resume and required skills for an assembler & quality control to have include:

- Part Numbers

- Quality Checks

- Assembly Line

- Safety Guidelines

- Control Panels

- R

- Quality Inspection

- Electrical Components

- Quality Standards

- Circuit Boards

- Tape Measure

- Soldering Irons

- ISO

- CNC

- QA

- Inventory Control

- Troubleshoot

- PCB

- PLC

- Clean Room Environment

- PC Boards

- Wire Harnesses

- Control Inspection

- Catheter

- Customer Specifications

- Assembly Drawings

- Product Quality

- Test Equipment

- Surface Mount

- Production Equipment

- Medical Devices

- Machine Operators

- IPC

- Blueprint Specifications

- Brazing

- Assembly Process

- BOM

- FDA

- SMT

- Tweezers

- Production Reports

- Chrysler

- Visual Inspections

- Production Process

Updated January 8, 2025