Automatically apply for jobs with Zippia

Upload your resume to get started.

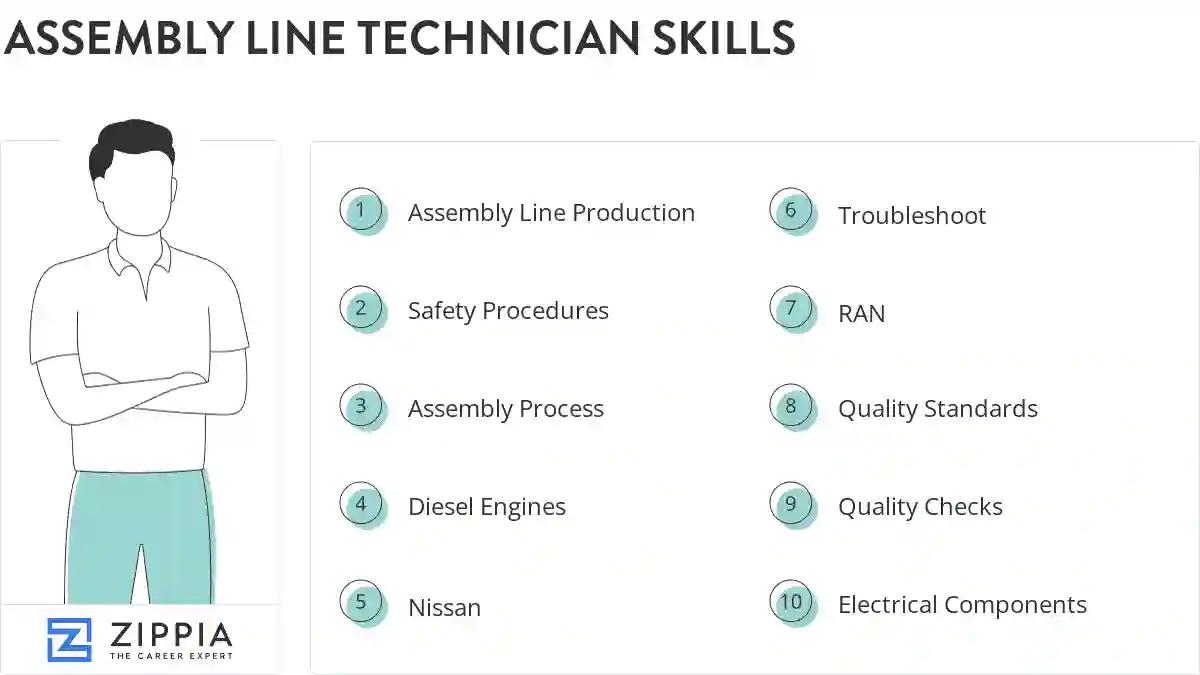

Assembly line technician skills for your resume and career

15 assembly line technician skills for your resume and career

1. Assembly Line Production

- Oversee assembly line production of ATV, UTV, and motorcycles.

- Improved assembly line production by 15% while working with group leader to streamline the operation.

2. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Followed safety procedures to maintain a safe work environment.

- Implemented airfield safety procedures, to ensure a safe operating environment for personnel and aircraft operation.

3. Assembly Process

- Worked as a team member in the assembly process for the Mack Truck Axle assembly line.

- Executed assembly processes on the chassis line; inspected parts for defects.

4. Diesel Engines

Diesel engines use an internal combustion technique that burns diesel oil in hot compressed air to propel a machine.

- Assembled diesel engines for a broad range of customers, including Ford Motor Company.

- Overhauled, rebuilt and repaired diesel engines and transmissions

5. Nissan

- Worked at the Nissan automobile manufacturing plant in Smyrna, Tennessee, as a technician in the Car Closures department.

- Worked with Nissan engineers and maintenance personnel on TPM projects to incorporate better ergonomics within the work center.

6. Troubleshoot

Troubleshooting is the process of analyzing and fixing any kind of problem in a system or a machine. Troubleshooting is the detailed yet quick search in the system for the main source of an issue and solving it.

- Assemble and build quality air conditioning units Operate and troubleshoot equipment effectively 5s and housekeeping Inventory management

- Assemble and troubleshoot several apparatus.

Choose from 10+ customizable assembly line technician resume templates

Build a professional assembly line technician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your assembly line technician resume.7. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Program E-proms, trained other employees, ran contact machine.

- Replaced temper seal, tape, and labels when the machines ran out.

8. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Work entails building motors in the assembly department and inspecting production to meet clients quality standards.

- Preform Mechanical Maintenance of production machine by executing daily preventive maintenance or maintenance as necessary to meet production and quality standards.

9. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Determined quality and usability of various engine components through quality checks.

- Performed in various maintenance and quality checks to ensure a great product.

10. Electrical Components

- Use of various tools to test voltage, Ohms, and other electrical components.

- Developed an understanding of various mechanical and electrical components and processes while manufacturing various types of projectors.

11. Circuit Boards

A circuit board refers to an electronic device used to offer mechanical support and connect components electrically using signal traces and conductive pathways.

- Inspected and tested the final product of all circuit boards.

- Assembled circuit boards for surge protectors

12. Air Tools

- Learned to drive a forklift and use power tools/air tools Safety is always paramount.

- Skilled in use of air tools, torque wrenches, hydraulic machines.

13. Assembly Problems

- Resolved assembly problems by altering dimensions to meet specifications; notifying supervisor to obtain additional resources.

- Resolved assembly problems by altering dimensions to meet specifications; notifying supervisor to obtain additional resources.

14. Safety Standards

- Ensured area cleanliness and safety standards were implemented in work area.

- Adhered to all OSHA workplace safety standards.

15. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Performed CNC precision sheet metal fabrication and structural modeling.

- Operated/monitored multiple specialized computer numerically controlled (CNC) machines.

5 Assembly Line Technician resume examples

Build a professional assembly line technician resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your assembly line technician resume.

What skills help Assembly Line Technicians find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of assembly line technician skills to add to your resume

The most important skills for an assembly line technician resume and required skills for an assembly line technician to have include:

- Assembly Line Production

- Safety Procedures

- Assembly Process

- Diesel Engines

- Nissan

- Troubleshoot

- RAN

- Quality Standards

- Quality Checks

- Electrical Components

- Circuit Boards

- Air Tools

- Assembly Problems

- Safety Standards

- CNC

- Jigs

- Production Targets

- Continuous Improvement

- AC

- Blueprint Specifications

- Assembly Operations

- Honda

- BMW

- A/C

- Toyota

- HVAC

- Production Equipment

- Equipment Operational

- Electrical Systems

- Inventory Control

- Assembly Stations

- Sigma

- Chrysler

- Jeep

- Stoves

Updated January 8, 2025