Automatically apply for jobs with Zippia

Upload your resume to get started.

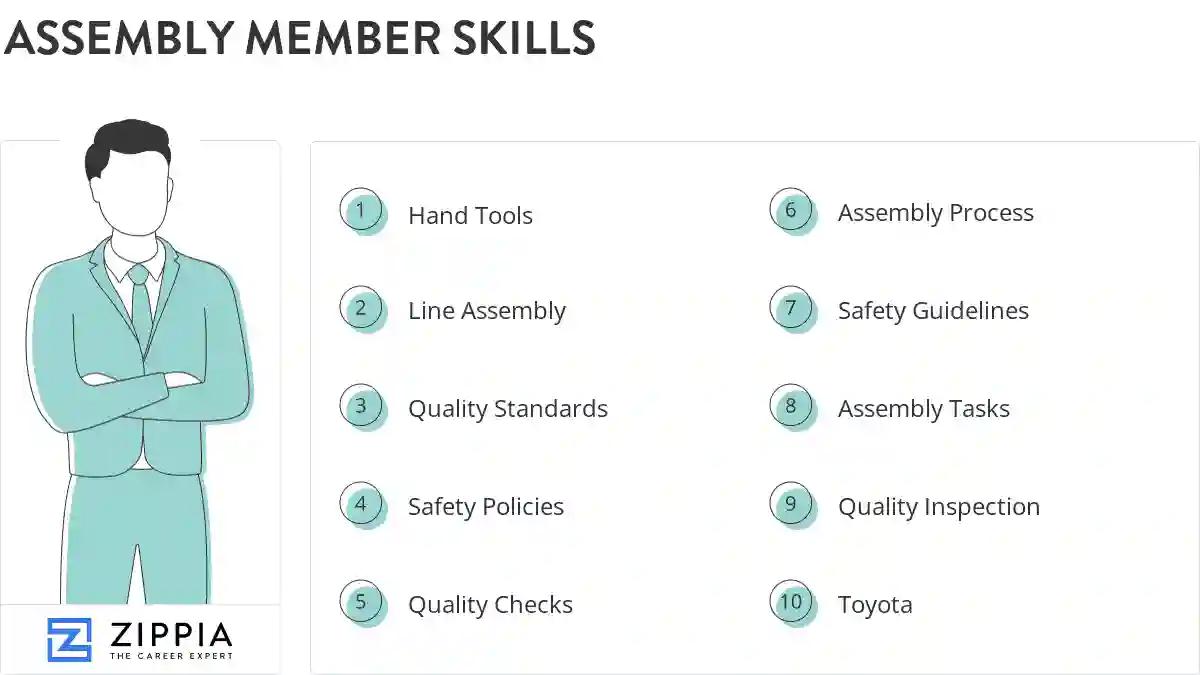

Assembly member skills for your resume and career

15 assembly member skills for your resume and career

1. Hand Tools

- Assembled electrical and Mechanical components for Coordinate Measuring Machines using hand tools.

- Operated and maintained hand tools, power equipment, drill machines, and measuring devices.

2. Line Assembly

- Perform various work station, line assembly, or production support operations to mass produce automobile components and/or automobiles.

- Performed and rated with 90 to 100 percent accuracy based on line assembly.

3. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Perform assembly of mechanical components and electronic controls meeting all product specifications, engineering drawings, work instructions and quality standards.

- Examined and assembled furniture product to ensure conformance to quality standards.

4. Safety Policies

Safety policies are the rules and codes of conduct developed by an organization to ensure workplace safety.

- Supported corporate environmental health safety policies.

- Operate forktruck and tow motor, deliver parts to assembly, follow OSHA safety policies, load and unload small parts.

5. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Performed computerized diagnostic quality checks.

- Work on the Assembly Line at Toyota presently, on 3rd shift * Install of automotive parts and conduct quality checks.

6. Assembly Process

- Proposed new methodologies for cost reduction and improved efficiency; eliminated bottlenecks in assembly process.

- Demonstrated accuracy in checking case differential Lash run-out during final assembly process.

Choose from 10+ customizable assembly member resume templates

Build a professional assembly member resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your assembly member resume.7. Safety Guidelines

Safety guidelines are regulations or rules governing procedures, actions, or devices with the aim of reducing the occurrence or risk of loss, injury, and danger to properties, individuals, or the environment. To adhere to the safety guidelines and be able to make the best possible decisions to ensure everyone at the workplace is safe, you should possess a wide range of skills.

- Follow regulation, safety guidelines, and company procedure Maintain clean work area Assemble frozen food packaging in a fast pace environment

8. Assembly Tasks

- Performed complex assembly tasks in limited time with very high accuracy and quality.

9. Quality Inspection

Quality inspections are measures to verify, examine or test various properties of one or more products and relate the results to the requirements to confirm compliance with the manufacturing processes. This is carried out to discover product defects and inform the management team for a decision on whether to approve or reject the product release.

- Circuit board assembly, quality inspection, general assembly, laser detail imaging operator

- General knowledge of quality inspection duties- defect detection, mutilation, and torque settings.

10. Toyota

- Welded seat frames for Toyota Manufacturing

- Work as assembly line team member installing parts and components to Large and small V8 engine block on the Toyota tundra.

11. Production Lines

- Have gained knowledge of every function of all production lines.

12. Door Panels

- Assemble incoming door panels, windshields, and door glass as well as inspect product for final installation.

- Used various power tools and welding equipment to fasten parts to make door panels for 2009 Honda pilot.

13. Air Tools

- Used air tools ranging from power drills, torque wrenches all the way to screw drivers.

14. Safety Standards

- Maintained company safety standards and assembly-line speed.

- Maintained work environment according to safety standards.

15. Power Drills

- Used hand power drills of different torque, multiple pliers, and plastic knives.

5 Assembly Member resume examples

Build a professional assembly member resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your assembly member resume.

What skills help Assembly Members find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of assembly member skills to add to your resume

The most important skills for an assembly member resume and required skills for an assembly member to have include:

- Hand Tools

- Line Assembly

- Quality Standards

- Safety Policies

- Quality Checks

- Assembly Process

- Safety Guidelines

- Assembly Tasks

- Quality Inspection

- Toyota

- Production Lines

- Door Panels

- Air Tools

- Safety Standards

- Power Drills

- Safety Procedures

- Troubleshoot

- Community Events

- Press Releases

- Customer Specifications

- Hyundai

- Customer Orders

- Production Targets

- ISO

- Quality Products

- Honda

- Production Process

- Product Orders

- Chrysler

Updated January 8, 2025