Automatically apply for jobs with Zippia

Upload your resume to get started.

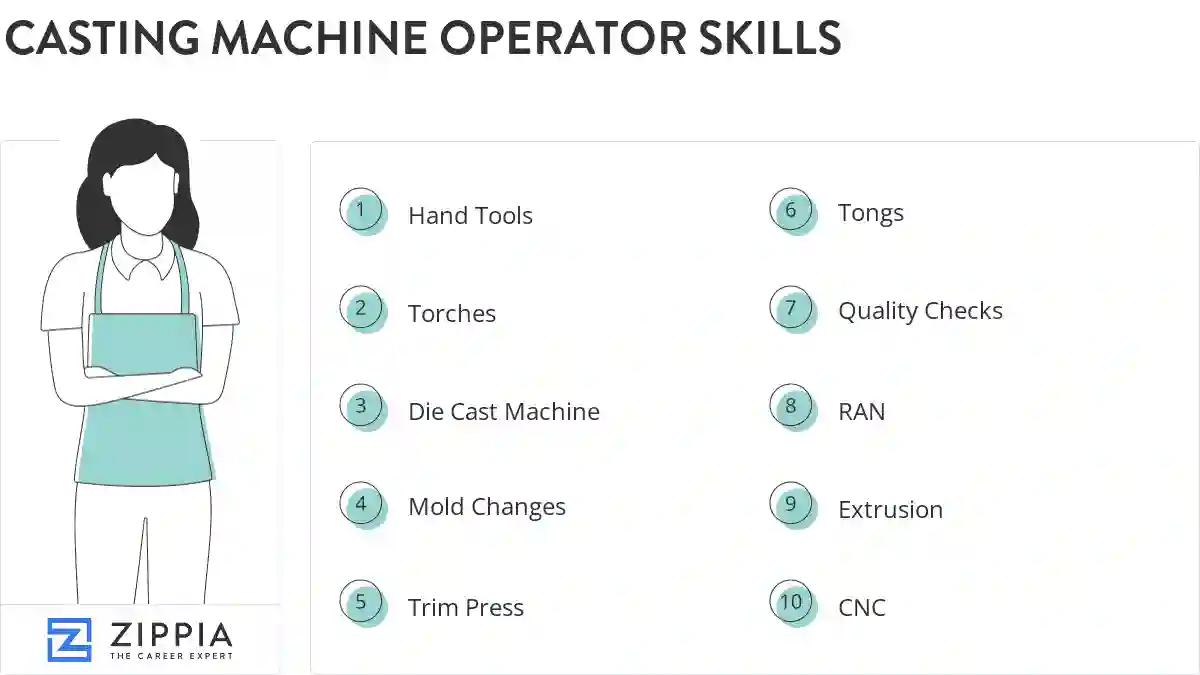

Casting machine operator skills for your resume and career

15 casting machine operator skills for your resume and career

1. Hand Tools

- Operate industrial saws, grinders, and a variety of hand tools in daily operations.

- Connected water hoses to cooling systems of dies, using hand tools.

2. Torches

- Spray, smoke, or coat molds with compounds to lubricate or insulate molds, using acetylene torches or sprayers.

- Spray molds with compounds of lubricate molds, using acetylene torches.

3. Die Cast Machine

- Operated a die cast machine, trim press, robots, charger bucket system for the furnace and related machinery.

- Repaired, operated, performed maintenance, and changed tools on 800 & 1200 Ton Die Cast Machines.

4. Mold Changes

Mold Changes refers to the act of altering a current mold used in product manufacturing. Any time the design of a product changes, whether just a component of the product or a mold of the entire product, the mold used must be changed.

- Cast quality parts clean, grind, and coat mold torch and preheat tubes and i can perform mold changes

- Mold changes Major to minor repairs Fill melting pots Inspect and pack parts

5. Trim Press

- Die casting machine operator, trim press operator, shipping and receiving, furnace operator loading trucks, and heat treat operator

- Die Cast Manufacturer, produce die castings, to instruction do machine setups, operate trim press.

6. Tongs

- Removed casting from mold, mold from press, using tongs or channel locks.

- Removed casting after die opened automatically, using pliers and tongs.

Choose from 10+ customizable casting machine operator resume templates

Build a professional casting machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your casting machine operator resume.7. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Apply procedures, perform required quality checks on product and equipment and take corrective actions when needed.

- Performed off-sets and tool changes, gauged parts, performed quality checks and completed set-ups.

8. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Exchange information with shifts before and after on where the product is going and how the machines ran.

- Grind castings according to specs, set up machines for different jobs to be ran

9. Extrusion

- Start up and fully run all casting machines Completes the Polymer extrusion process Assist in maintenance of casting machines.

- Work with injection molding manufacturing hospital product parts -Operated machines in departments of extrusion and injection molding -Experience with digital calipers.

10. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- X-ray certified to look for internal air in parts production and fix prior to CNC usage

- Machine Operator, worked two fields Gravity Die-Casting Machine Department and CNC Machine Side.

11. Automatic Machines

- Observe continuous operation of automatic machines to ensure that products meet specifications and to detect jams malfunctions making adjustments as necessary.

- Observe continuous operation of automatic machines to ensure that products meet specifications.

12. Continuous Operation

- Observed continuous operation of automatic machine and width and alignment of plastic sheeting to ensure side flanges.

- Implemented preventative maintenance techniques to ensure tools were in continuous operation, promoting efficiency and productivity.

13. Dimension Defects

- Measured and visually inspected products for surface and dimension defects to ensure conformance to specifications.

- Measured and visually inspected products for surface and dimension defects to ensure conformance to specifications, using precision measuring instruments.

14. Press Machine

- Hand ladle molten aluminum into machine and extract finished product from machine.Use of punch press machines also.

- Performed troubleshooting and basic maintenance of stamp press machinery.

15. Rakes

- Skimmed or poured dross, slag, from molten metal, using rakes.

5 Casting Machine Operator resume examples

Build a professional casting machine operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your casting machine operator resume.

What skills help Casting Machine Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of casting machine operator skills to add to your resume

The most important skills for a casting machine operator resume and required skills for a casting machine operator to have include:

- Hand Tools

- Torches

- Die Cast Machine

- Mold Changes

- Trim Press

- Tongs

- Quality Checks

- RAN

- Extrusion

- CNC

- Automatic Machines

- Continuous Operation

- Dimension Defects

- Press Machine

- Rakes

- Production Process

- Nonferrous Metals

- Assembly Line

- Preheat

- Grinding Wheels

- Oiling

- Toyota

- Surface Defects

- Honda

- Quality Products

- Hoists

Updated January 8, 2025