Automatically apply for jobs with Zippia

Upload your resume to get started.

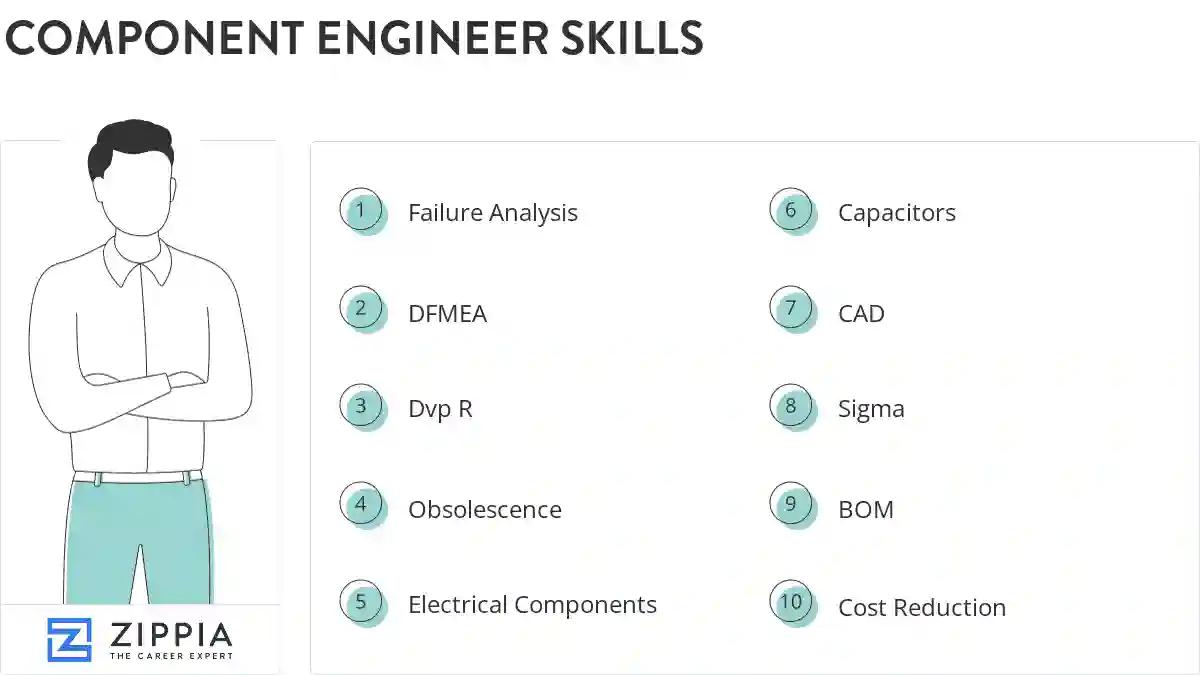

Component engineer skills for your resume and career

15 component engineer skills for your resume and career

1. Failure Analysis

Failure Analysis is a step-by-step process of determining the reason for a particular machine or equipment failure by way of checking, identification, and examination. It means conducting a test within the system and perform a maintenance check that leads you to a conclusion. A failure analysis takes place to prevent further damages.

- Conducted failure analysis of microelectronic components and lab analysis of warranty return components utilizing various testing equipment and recording resulting data.

- Gained additional practical technical experience and problem solving skills through failure analysis related to various products and components.

2. DFMEA

- Collaborate with suppliers and Engineering team members to author DFMEA and DVP&R documents.

- Developed DFMEA and DVP&R for body sealing components of a car.

3. Dvp R

- Led testing and validation of sub-systems and cockpit for material properties, design integrity, and passing all DVP requirements.

4. Obsolescence

- Managed obsolescence issues by closely monitoring all PCN activity via various commercial services.

- Developed procedure and created reports for parts obsolescence studies of military vehicle assemblies.

5. Electrical Components

- Provided sourcing and alternate sourcing for electrical components and obsolete/hard to find devices.

- Performed failure analyses on a variety of electrical components.

6. Capacitors

- Researched / identified / selected unique vibration resistant electrolytic capacitors.

- Proved the capacitors should be removed and replaced without cost to SSL under standard product warranty.

Choose from 10+ customizable component engineer resume templates

Build a professional component engineer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your component engineer resume.7. CAD

- Reduced CAD drawing time of Specifications and Drawings to hours from up to 2 weeks using Snag-It.

- Support during program launches, using the APQP process, provides product design, CAD drawings.

8. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Led a Lean/Six Sigma Green Belt project to reduce the company's non-conformance reports (NCR) using the DMAIC process.

- Achieved Design for Six Sigma Black Belt certification.

9. BOM

BOM stands for a bill of materials in design drafting. This list outlines the raw materials, instructions, and components required to manufacture or construct a product or service.

- Body Engineering coordinator and pilot team representative for new prototype/production BOM management system.

- Performed BOM review to screen out EOL, obsolete, non-standard / mixed components before preliminary BOM released to manufacturing.

10. Cost Reduction

- Provided component where-used and volume estimates to the corporate commodity managers for targeting specific areas of cost reduction through price negotiation.

- Provided alternate components for cost reduction, quality improvement, and manufacturing lead time reduction.

11. UL

- Created component specification standards including specifying the critical to quality parameters and for UL and NEBS compliance requirements.

- Acquired UL approval for a 3-wire input into a Phoenix terminal connector to gain a market advantage.

12. Part Numbers

Part Numbers are special sets and strings of numbers used to identify and label parts. There is no one specific kind or set of parts for which this is used and the term can be found in various industries and used for various parts. Most often, a part number is only used to refer to one part and product within one company or organization. Part numbers, also, tend to inadvertently describe the item's purposes and physical features, too, through an organized code of sorts.

- Standardized manufacturers' names and part numbers and then loaded completed file into a web-based solution tool and performed final validation.

- Documented in the ERP system, new company part numbers, created source control drawings, and maintained Approved Vendor List.

13. GD

GD refers to Grade Delay and is often mentioned on report cards or academic records when the instructor of a particular subject decides to hold the grade of a student. This is usually done if the instructor wants the student to improve their grade by retaking the exam or doing something for extra credit that will ultimately enhance their overall grade. Eventually, when the grade is assigned, the GD is then replaced with the original grade.

- Trained in GD & T workbook and in various other industry standards.

- Performed mechanical and electrical drafting while using GD & T standards.

14. EOL

- Provided technical component support to Design Engineering and assisted with the identification and selection of alternate component sources and EOL evaluation.

- Review End of Life (EOL) notices to allow graceful transition from existing to future technologies.

15. Component Selection

- Worked closely with designers and suppliers to ensure electronic component selections meet both quality expectations and product performance requirements.

- Assisted design engineers in component selection, cataloged component data and provided source information for procurement.

5 Component Engineer resume examples

Build a professional component engineer resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your component engineer resume.

What skills help Component Engineers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

What skills stand out on component engineer resumes?

Charles Jenckes

Assistant Professor, University of North Carolina at Charlotte

1.Where the candidate went to school and what was studied

2.GPA

3.Any successful internships

4.Projects completed by the student

What component engineer skills would you recommend for someone trying to advance their career?

Dr. Yousef Sardahi

Associate Professor of Mechanical Engineering, Marshall University

Advanced Computational Skills: Proficiency in simulation and modeling software (like ANSYS, SolidWorks, or MATLAB) will be crucial as these tools become more integral in designing and testing complex systems.

Robotics and Automation: With industries moving towards automation, skills in robotics, automated systems, and knowledge of AI integration will be highly sought after.

Additive Manufacturing and 3D Printing: Expertise in 3D printing and additive manufacturing techniques will be valuable as these technologies revolutionize product development and manufacturing processes.

Renewable Energy Technologies: As the world shifts towards sustainable energy sources, mechanical engineers with knowledge in solar, wind, and other renewable energy technologies will be in high demand.

Data Analysis and IoT: Skills in data analytics and understanding the Internet of Things (IoT) will be important as more mechanical systems are connected and produce large amounts of data.

Materials Science: Knowledge in advanced materials, such as composites or smart materials, will be crucial for developing more efficient and sustainable products and systems.

Systems Engineering and Integration: The ability to understand and integrate various subsystems within a larger system will be key, especially in complex projects.

Project Management and Leadership: As projects become more complex, skills in project management and leadership will be essential for overseeing projects and leading teams effectively.

Interdisciplinary Collaboration: The ability to work effectively across disciplines, understanding aspects of electrical engineering, computer science, and even business, will be increasingly important.

Communication and Soft Skills: Strong communication skills, both for technical and non-technical audiences, along with teamwork and problem-solving skills, will always be invaluable in the engineering field.

What hard/technical skills are most important for component engineers?

Mike DeVore Ph.D.

Professor & Program Chair, Cincinnati State Technical & Community College

-Knowledge of manufacturing processes

-A good mathematics foundation

-Technical communication

-Problem solving

List of component engineer skills to add to your resume

The most important skills for a component engineer resume and required skills for a component engineer to have include:

- Failure Analysis

- DFMEA

- Dvp R

- Obsolescence

- Electrical Components

- Capacitors

- CAD

- Sigma

- BOM

- Cost Reduction

- UL

- Part Numbers

- GD

- EOL

- Component Selection

- Product Development

- Transistors

- EEE

- Test Data

- Design Reviews

- Technical Support

- PCB

- Corrective Action

- RF

- Lifecycle Management

- RoHS

- Component Suppliers

- Engineering Support

- Component Issues

- ISO

- Part Selection

- Resistors

- CE

- Component Specifications

- Test Procedures

- NPI

- ECO

- PC

- R

- Commodities

- Electro-Mechanical Components

- Power Electronics

- FMEA

- Cycle Management

- Component Data

- DPA

- Cots

- Manufacturing Support

Updated January 8, 2025