Automatically apply for jobs with Zippia

Upload your resume to get started.

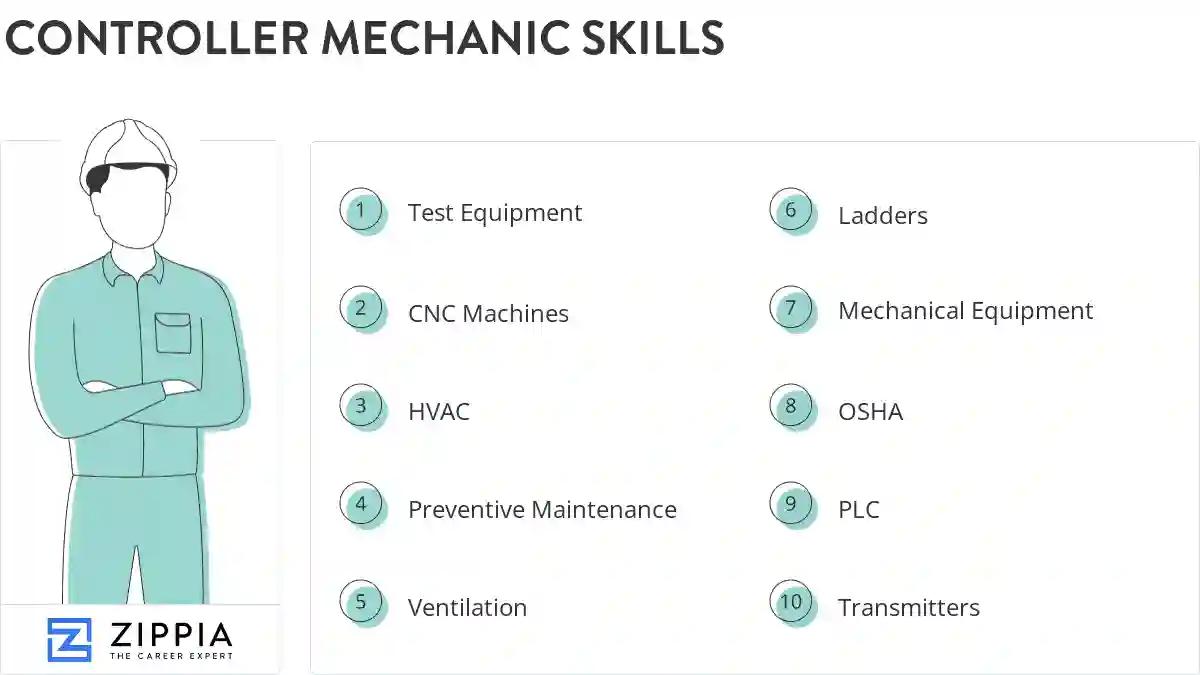

Controller mechanic skills for your resume and career

15 controller mechanic skills for your resume and career

1. Test Equipment

Test equipment is a mechanical tool or a device which is used create signals and gather response from an electronic device under test. It helps in detecting any faults in the device and it also proves the proper operation of the electronic device.

- Diagnosed malfunctions using technical orders, schematics, wiring diagrams, built-in-tests (BIT), and other test equipment.

- Used test equipment to locate sources of problems, Made required modifications and adjustments to UMCS.

2. CNC Machines

- Performed all levels of repair on multiple 5-axis CNC machines at an Aero-structural fabrication facility

- Service and repair CNC machines Rebuilt Turrets, linear guides, magazines etc.

3. HVAC

- Advised and trained Facilities HVAC mechanics on system configuration and component selection and operation.

- Maintained commercial and industrial heating, ventilation, HVAC equipment, and controls including individual systems feeding into the EMCS.

4. Preventive Maintenance

- Perform routine preventive maintenance on highly specialized production equipment used for toxic chemicals and hazardous materials.

- Perform preventive maintenance on DDC systems and methane sensors.

5. Ventilation

- Use machines such as grinders, solvent cleaner tubs, ventilation hoods and load tester.

- Perform repairs on engines auxiliary power unit, and ventilation and heating systems.

6. Ladders

- Work from ladders, scaffolds, and roofs to install, maintain or repair electrical wiring, equipment, and fixtures.

- Required to stand for long periods of time, bend often, climb ladders, and squat for heavy lifting.

7. Mechanical Equipment

Mechanical equipment is a term referring to the machinery which have been created and gathered for the purpose of fulfilling one or more functions and consisting of, most often, multiple components.

- Supervised preventative and corrective maintenance as well as testing and repairs of mechanical equipment to include replacing mechanical components and parts.

- Developed written troubleshooting plans to analyze malfunctions to mechanical equipment to determine and repair root cause of failures.

8. OSHA

- Take immediate corrective action regarding unsafe conditions and always abiding by OSHA regulations.

- Maintained a level of qualifications as required by applicable OSHA, ASTM and ANSI standards, and site accredited training programs.

9. PLC

- Designed PLC ladderdiagrams for gate control systems and water system process with Mitsubishi (FX Series) PLC.

- Supervised staff of six technicians in calibration of temperature/pressure sensors and in full PLC validation testing.

10. Transmitters

- Replaced and upgraded hardwire fire alarm transmitters and communication cables to the Monaco Radio Transmitter and Antenna.

11. Logic Controllers

- Performed troubleshooting on Programmable Logic Controllers integrated with the steamgenerators and turbines.

12. Switches

- Configured Microsoft Active Directory, Microsoft Exchange, Cisco firewall, routers, switches, installed andconfigured Windows 2003 server.

- Clamp and crank switches, Running cables, Meggering, relay testing diagram reading and interpretation.

13. Variable Frequency

A Variable-Frequency Drive is a kind of motor that varies the voltage and frequency sent to an electric motor. This variation provides for more power-efficient equipment and technology, which saves energy, and also produces less noise in electronics such as pumps and fans. Because of these and other features, electronics with a variable-frequency drive (VFD) also typically have longer lifespans than other electronics.

- Increase Fans and Pumps efficiency by installing and commissioning Variable Frequency Drives.

- Tested and repaired electric motors, variable frequency drives, alarms and control systems.

14. Hydraulic Systems

- Recognized for working knowledge of control loops, PLCs, relay logic, hydraulic systems, and pneumatic systems.

- Performed corrective organizational maintenance on previously diagnosed malfunctions of mechanical, electrical, and hydraulic systems and or components.

15. Hazardous Materials

Any substance or good that is harmful to human health as well as the environment are called hazardous materials. Such materials must be handled carefully to avoid any mishaps. Harmful gases. chemicals, strong medicines or drugs, radioactive elements required for radiation purposes, a human blood sample that carries germs, all of these are considered hazardous materials.

- Collected and disposed of hazardous materials.

- Fabricated parts using metal forming techniques and fiberglass materials, apply primers/paints on aircraft surfaces and maintained facilities storing flammable/hazardous materials.

What skills help Controller Mechanics find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of controller mechanic skills to add to your resume

The most important skills for a controller mechanic resume and required skills for a controller mechanic to have include:

- Test Equipment

- CNC Machines

- HVAC

- Preventive Maintenance

- Ventilation

- Ladders

- Mechanical Equipment

- OSHA

- PLC

- Transmitters

- Logic Controllers

- Switches

- Variable Frequency

- Hydraulic Systems

- Hazardous Materials

- Electrical Equipment

- Technical Manuals

- Mechanical Drawings

- Cranes

- Ac

- Dc

- Engineering Drawings

- Electrical Troubleshooting

- Control Panels

- Technical Orders

- Shop Equipment

- Unscheduled Maintenance

- Production Equipment

- Equipment Repair

- Cooling Towers

- Hand Tools

- Depot

- Fire Alarm Systems

- Microprocessors

- Mechanical Problems

- Assembly Line

- CPR

Updated January 8, 2025