Automatically apply for jobs with Zippia

Upload your resume to get started.

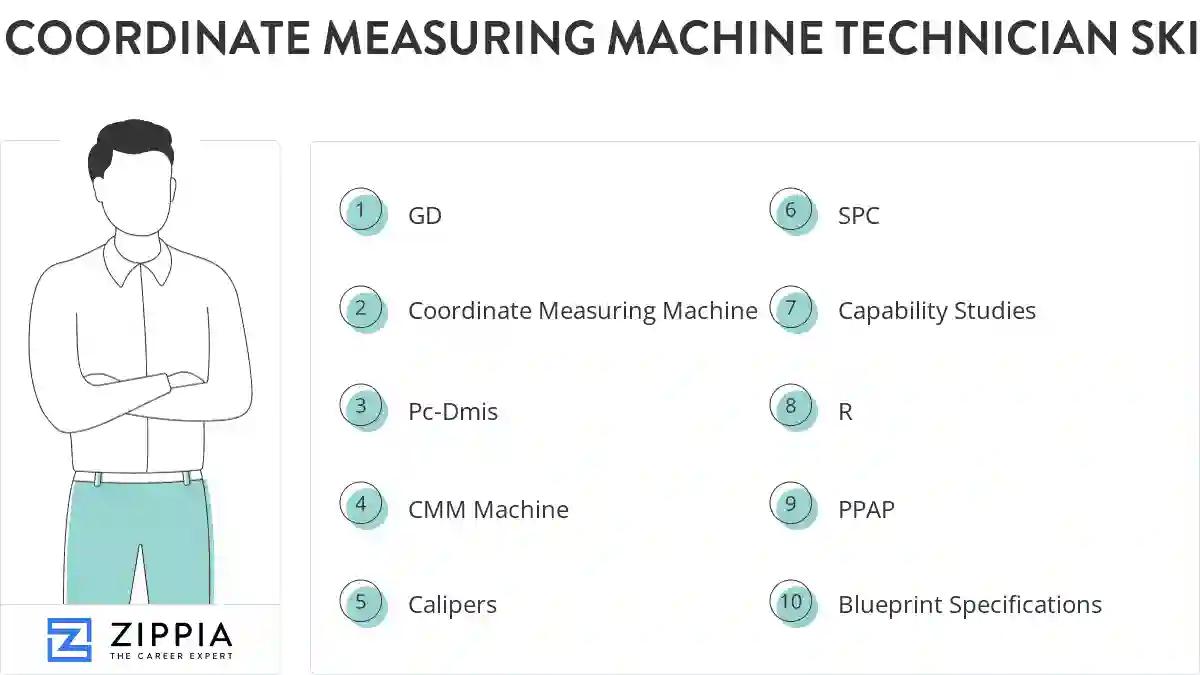

Coordinate measuring machine technician skills for your resume and career

10 coordinate measuring machine technician skills for your resume and career

1. GD

GD refers to Grade Delay and is often mentioned on report cards or academic records when the instructor of a particular subject decides to hold the grade of a student. This is usually done if the instructor wants the student to improve their grade by retaking the exam or doing something for extra credit that will ultimately enhance their overall grade. Eventually, when the grade is assigned, the GD is then replaced with the original grade.

- Blueprint reading with GD &T..

- Insured accuracy of bores and surfaces by GD & T.* Calibrated and set up CMM fixtures for daily operation.

2. Coordinate Measuring Machine

- Operate and program several types of coordinate measuring machines and video measuring system.

- Program and operate Coordinate Measuring Machine using Virtual DMIS and Capps and Edges

3. Pc-Dmis

- Created and maintained CMM programs using PC-DMIS, ensuring that the highest quality standards are maintained.

- Developed competency in the basic uses of PC-DMIS software Inspected parts on CMM

4. CMM Machine

- Performed CMM fixture set-up and maintain CMM calibrations, CMM machine preventive maintenance, and write CMM inspection program routines.

- Maintained cleanliness of CMM Machine to ensure the most accurate measurement readings.

5. Calipers

- Perform calibration of Micrometers and Calipers.

- Measured dimensions of products to verify conformance to specifications, using measuring instruments including calipers and gauges.

6. SPC

SPC stands for "statistical process control," a method that uses statistical tools and charts to analyze a process or procedure over time. This could reveal an error in production or an internal system by highlighting data points outside the expected results. These anomalies, likely caused by outside sources, can then be studied and remedied.

- Ensured adherence to SPC requirements and oversaw data collections to communicate required adjustments and/or corrections to management and engineering teams.

- Verify part conformance to specification of injection molded components according to requirements detailed on inspection cards or SPC files.

7. Capability Studies

- Developed Capability studies to determine present standards then established proposed quality and reliability expectancy of finished product.

- Monitor and/or update coordination of a receiving inspection/audit procedure, capability studies, and measurement standards.

8. R

R is a free software environment and a language used by programmers for statistical computing. The R programming language is famously used for data analysis by data scientists.

- Complete capabilities and Gauge R and R for machines and components.

- Perform Gage R and R and calibrate required equipment.

9. PPAP

- Ensured quality and consistency across various product lines through Production Part Approval Process (PPAP) inspections.

- Prepare Production Parts Verification reports (PPV, PPAP) as determined by CMM data.

10. Blueprint Specifications

Blueprints are layouts or designs about the construction of a building or structure. It consists of accurate engineering drawing on light-sensitive sheets allowing to create copies easily.

- Measured tool dyes to ensure all were to blueprint specifications for quality components.

What skills help Coordinate Measuring Machine Technicians find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of coordinate measuring machine technician skills to add to your resume

The most important skills for a coordinate measuring machine technician resume and required skills for a coordinate measuring machine technician to have include:

- GD

- Coordinate Measuring Machine

- Pc-Dmis

- CMM Machine

- Calipers

- SPC

- Capability Studies

- R

- PPAP

- Blueprint Specifications

Updated January 8, 2025