Automatically apply for jobs with Zippia

Upload your resume to get started.

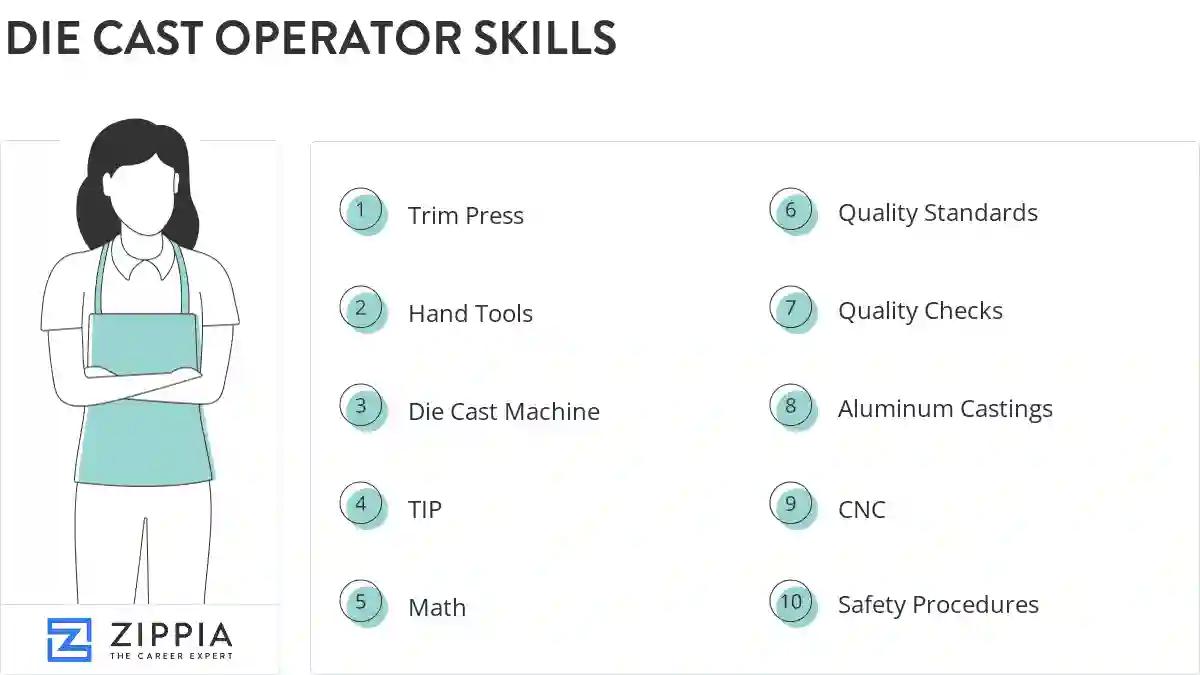

Die cast operator skills for your resume and career

15 die cast operator skills for your resume and career

1. Trim Press

- Inspect parts to make sure they are quality, trimmed parts with trim press while working as a Die Cast Operator.

- Take parts from die, and trim on trim press and inspection of parts.the use of calibers and special gauges.

2. Hand Tools

- Operated automatic compression/sonic weld machines and used various hand tools to assemble various components into finished product.

- Replaced defective or improperly functioning circuitry or electronics components, using hand tools or soldering iron.

3. Die Cast Machine

- Operated die cast machinery, inspected and packaged parts and recorded measurements and documentation.

- Operated aluminum injection robotic die cast machines.

4. TIP

- Poured shots in sleeves by using a ladel sprayed die repaired shot arm or tip reading blue prints.

5. Math

- Achieved enhancement in shop math: trigonometry, compound angles, and geometry.

- used basic math skills to count parts threw out the day.

6. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Inspected finished products for imperfections, assuring the product met Quality Standards.

- Maintain quality standards by approving material at in-process inspection for all products verify conformance to specified dimensions.

Choose from 10+ customizable die cast operator resume templates

Build a professional die cast operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your die cast operator resume.7. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Required to perform quality checks as needed, and maintain the integrity and cleanliness of all equipment.

- Performed quality check first time inspections of product.

8. Aluminum Castings

- Die Caster Responsibilities include: Die Caster of aluminum castings and trimmer

9. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Operated a cnc robotic helium arc welder, under water plasma cutter and a seam welder.

- Operated and retool CNC and conventional manufacturing equipment.

10. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Train new hires on machine operation, paperwork and safety procedures.

- General Duties-Keep work area clean, complied with all safety procedures

11. SPC

SPC stands for "statistical process control," a method that uses statistical tools and charts to analyze a process or procedure over time. This could reveal an error in production or an internal system by highlighting data points outside the expected results. These anomalies, likely caused by outside sources, can then be studied and remedied.

- Performed Statistical Process Control (SPC), including data collection, charts and graphs on my first two parts.

- Fill out necessary SPC Charts hourly for my production status and tracking periods for an automotive manufacturing plant.

12. Punch Press

- Worked at piece work rate on punch press and drill press machines.

- Changed out dies for punch presses, and die-cast machines.

13. Press Machine

- Molded aluminum parts using press machinery.

- Die Cast Operator (Cutting, Punching, and Press Machine Setters, Operators, and Tenders, Metal and Plastic)

14. Troubleshoot Problems

- Monitor operation of machines and troubleshoot problems as needed.

15. Automatic Machines

- Observe continuous operation of automatic machines to ensure that products meet specifications and to detect jams malfunctions making adjustments as necessary.

- Observe continuous operation of automatic machines to ensure that products meet specifications.

5 Die Cast Operator resume examples

Build a professional die cast operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your die cast operator resume.

What skills help Die Cast Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of die cast operator skills to add to your resume

The most important skills for a die cast operator resume and required skills for a die cast operator to have include:

- Trim Press

- Hand Tools

- Die Cast Machine

- TIP

- Math

- Quality Standards

- Quality Checks

- Aluminum Castings

- CNC

- Safety Procedures

- SPC

- Punch Press

- Press Machine

- Troubleshoot Problems

- Automatic Machines

- Mowers

- Continuous Operation

- Cast Process

- Assembly Line

- PPE

- Hoists

- Quality Inspection

- Torches

- Dimension Defects

- Quality Products

- Skim

- Drill Press

- ISO

- Tongs

- Safety Regulations

- Tig Welding

- Chrysler

- FANUC

- Production Process

- Quality Issues

- Production Runs

- CMM

Updated January 8, 2025