Automatically apply for jobs with Zippia

Upload your resume to get started.

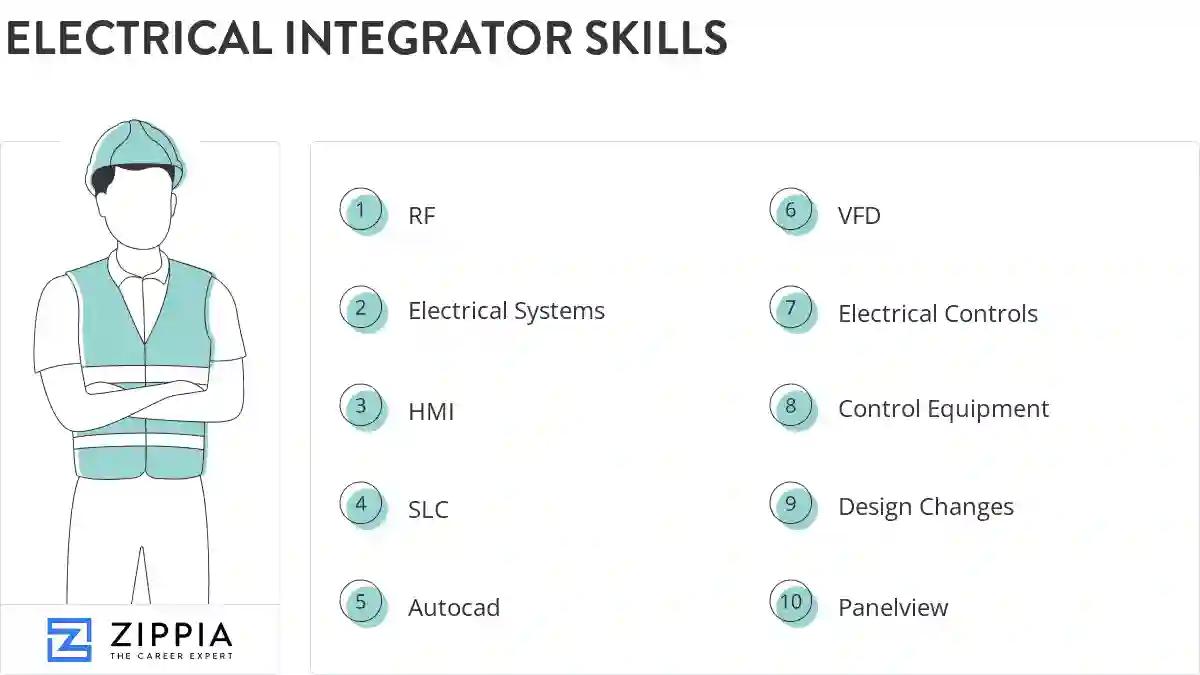

Electrical integrator skills for your resume and career

12 electrical integrator skills for your resume and career

1. RF

- Developed RF products based on low to high level implementation specifications based on customer or requests or company design modification requirements.

- Developed and analyzed prototype electronic RF circuits for improvement and modifications of Radar Systems to meet customer requirements.

2. Electrical Systems

- Contract position that developed and maintained machine electrical systems to support the different Forest Products, and variable margin improvement initiatives.

- Hold responsibility for requirements gathering, designing electrical systems, load calculations, equipment selection, project management and coordination.

3. HMI

A human-machine interface is a dashboard or user interface that connects an operator to a device, system, or machine.

- Control equipment included:1 PLC, 1 HMI, 1 Servo, 3 Robots / vision systems.

- Control equipment included: 1 PLC, 1 HMI, 5 Freq Drives, 1 Robot.

4. SLC

- Control equipment included AB SLC 500, AB ControlLogix 5000, PanelView, PanelView Plus and RSView32.

- Control equipment included: SLC 505 processor and FactoryTalk View ME operator interface.

5. Autocad

- Design supported with Visual Engineer and AutoCAD.

- Design Electrical Systems predominantly for building construction projects including power distribution systems, lighting, and other signal systems using AutoCAD.

6. VFD

- Programmed, Installed, and Maintained Mitsubishi, and Allen Bradley VFD's.

- Completed PLC/HMI program testing and modification and VFD programming.

7. Electrical Controls

Electrical control is a physical connection of electrical devices that are controlled by switches, relays, or rheostats and that influence the dynamic behavior of other devices or systems through control loops.

- Upgraded electrical controls for nineteen vessels with intrinsically safe - XP rated components.

- Provided electrical controls engineering support for five separate can line conveyor projects and two de-palletizers.

8. Control Equipment

- Control equipment included: ControlLogix 5000 PLC and FactoryTalk View ME operator interface.

9. Design Changes

- Interfaced with customer to work out design changes and assist during both on-site and off-site acceptance runs.

10. Panelview

- Implemented a PanelView Plus 1250 operator interface station to remotely control the rail car dump dust suppression system.

11. Variable Frequency

A Variable-Frequency Drive is a kind of motor that varies the voltage and frequency sent to an electric motor. This variation provides for more power-efficient equipment and technology, which saves energy, and also produces less noise in electronics such as pumps and fans. Because of these and other features, electronics with a variable-frequency drive (VFD) also typically have longer lifespans than other electronics.

- Examined and repaired variable frequency drives.

12. BOM

BOM stands for a bill of materials in design drafting. This list outlines the raw materials, instructions, and components required to manufacture or construct a product or service.

- Maintain Bill of Material (BOM) and issue change orders as needed to reflect changes for the most optimal design.

- Create, order and follow the Electrical BOM out the door assembled and/or as ship loose parts.

What skills help Electrical Integrators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of electrical integrator skills to add to your resume

The most important skills for an electrical integrator resume and required skills for an electrical integrator to have include:

- RF

- Electrical Systems

- HMI

- SLC

- Autocad

- VFD

- Electrical Controls

- Control Equipment

- Design Changes

- Panelview

- Variable Frequency

- BOM

Updated January 8, 2025