Automatically apply for jobs with Zippia

Upload your resume to get started.

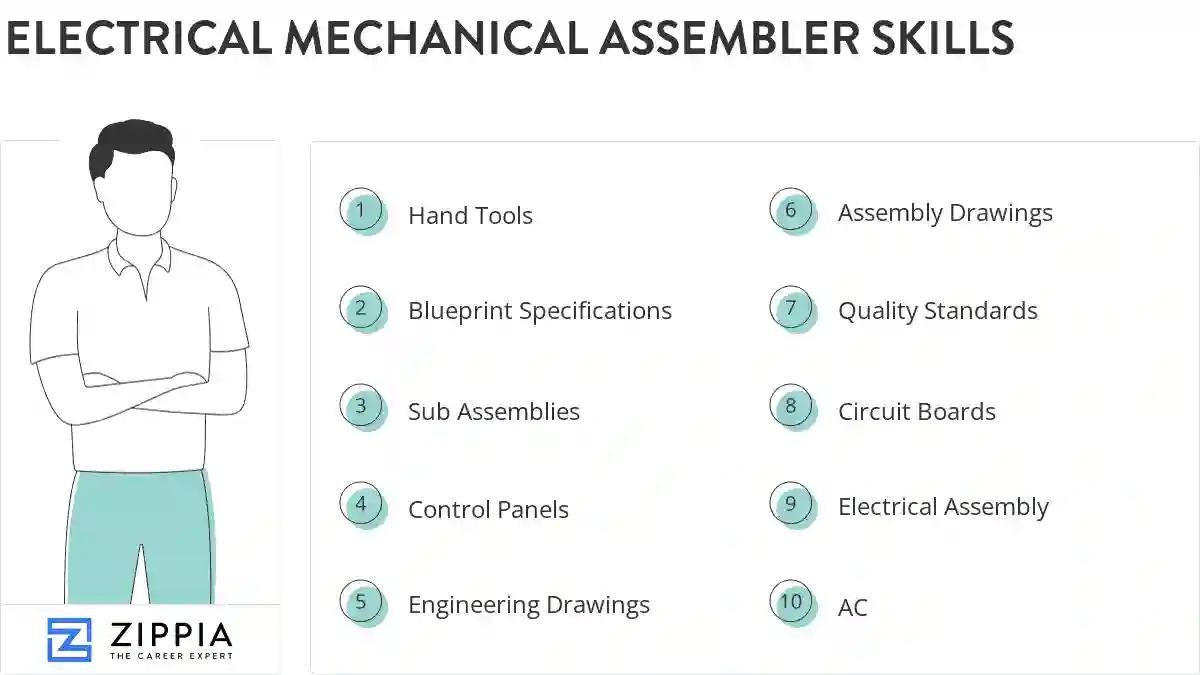

Electrical mechanical assembler skills for your resume and career

15 electrical mechanical assembler skills for your resume and career

1. Hand Tools

- Aligned, fit and assembled component parts, using hand tools, power tools, fixtures, templates, and microscopes.

- Used standard hand tools as well as specialty tools to assemble joy sticks, track balls, and hand controls.

2. Blueprint Specifications

Blueprints are layouts or designs about the construction of a building or structure. It consists of accurate engineering drawing on light-sensitive sheets allowing to create copies easily.

- Measured products according to blueprint specifications and tracked to ensure specifications were met.

- Make setups and adjustments holding all tolerances to blueprint Specifications.

3. Sub Assemblies

Sub-assembly is the process of combining or building components into component assemblies for inclusion in larger final products. It is the combination of components to create a new parent that requires assembly. It can be replaced in its entirety, but some of its parts can be replaced individually. Therefore, it is a manufacturing process in itself. The subassembly process makes manufacturing more efficient. With the subparts already assembled, the final product can be assembled much faster. Starting with a base, component parts are attached and incorporated to form a completely new item. Sub-assemblies may also need to be customized for specific end items.

- Assembled and modified electrical and mechanical sub assemblies, (electrical cables, throttle assemblies).

- Assemble sub assemblies/lighting systems (high & low voltage) for airport runways per schematic/blueprint.

4. Control Panels

A control panel is a flat, enclosed unit, often the vertical part of a system in which the control or monitoring instruments are displayed and accessible to users. Control panels are typically closed-circuit boards with connections to all peripheral devices in their area. They can be found in factories to monitor and control machines or production lines and in places like nuclear power plants, ships, airplanes, and mainframe computers.

- Constructed and wired electrical control panels.

- Performed panel lay-out and determined proper wire sizes prior to assembly, reading of electrical drawings, and building control panels.

5. Engineering Drawings

Engineering drawings are technical drawings that tell about the requirements for engineering components or equipment. Such drawings have standardized languages and symbols. There are multiple types of engineering drawings such as isometric drawing, orthographic or multiview drawing, schematic drawings, one view, and two view drawings, etc.

- Performed assembly of components according to engineering drawings and quality standards which decreases waste.

- Worked effectively from engineering drawings, product structures and control documents.

6. Assembly Drawings

- Ensured proper assembly by using printed documentation assembly drawings, blue prints and verbal instruction.

- Assembled, per assembly drawings, blueprints and electrical schematics, electrical and mechanical instruments.

Choose from 10+ customizable electrical mechanical assembler resume templates

Build a professional electrical mechanical assembler resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your electrical mechanical assembler resume.7. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Performed all work with quality standards and established safety precautions

- Assembled products to meet scheduled deadlines by using approved assemble methods within standard times while maintaining high quality standards.

8. Circuit Boards

A circuit board refers to an electronic device used to offer mechanical support and connect components electrically using signal traces and conductive pathways.

- Soldered electrical components onto circuit boards.

- Connect lead wires to printed circuit boards Install finished assemblies, attaching hardware, switches, or other parts.

9. Electrical Assembly

- Performed wiring, mechanical and electrical assembly of battery back-up systems.

- Read and followed schematics to provide quality in electrical assembly.

10. AC

- Test portable AC unit used in military trailer and SAP train as well.

- Wired AC - DC power devices.

11. Electrical Components

- Wired and soldered electrical components to include but not limited to switches, relays, thermostats, motors and junction boxes.

- Installed and assembled electrical components, in units, using engineer drawings and schematics.

12. Electro-Mechanical Assembly

- Perform a wide range of complex electro-mechanical assembly operations.

- Perform required Optical, electro-mechanical assembly, alignment, calibration of subassembly or system level hardware.

13. PLC

- Manufactured PLC control cabinets for high temperature ovens.

- Performed PLC installation and troubleshooting.

14. Electronic Components

Electronic Components refer to the structure of a circuit that controls and directs electric current to perform various tasks. These functions include signal computation, amplification, and data transfer. It includes several components such as resistors, capacitors, inductors, transistors, or diodes and connected using conductive wires or traces. Though, a circuit is complete only when it forms a loop.

- Performed installations of electric and electronic components for power generation cabinets.

- Assembled electronic components using various types of power tools

15. Assembly Operations

- Retain knowledge of assembly operations.

- Performed assembly operations on structural parts of the aircraft as well as required fixture and bench assembly operations.

5 Electrical Mechanical Assembler resume examples

Build a professional electrical mechanical assembler resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your electrical mechanical assembler resume.

What skills help Electrical Mechanical Assemblers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of electrical mechanical assembler skills to add to your resume

The most important skills for an electrical mechanical assembler resume and required skills for an electrical mechanical assembler to have include:

- Hand Tools

- Blueprint Specifications

- Sub Assemblies

- Control Panels

- Engineering Drawings

- Assembly Drawings

- Quality Standards

- Circuit Boards

- Electrical Assembly

- AC

- Electrical Components

- Electro-Mechanical Assembly

- PLC

- Electronic Components

- Assembly Operations

- Tweezers

- Assembly Process

- Trouble Shoot

- Electrical Equipment

- Drill Press

- Wire Harnesses

- Jigs

- Electrical Schematics

- Electrical Tools

- Electrical Panels

- Torque Wrenches

- Switchboards

- Electrical Drawings

- Circuit Breakers

- CNC

- Test Equipment

- ISO

- PCB

- Assembly Line

- Schematic Drawings

- Install Components

- Electrical Systems

- IPC

- Mechanical Drawings

- PC

- BOM

- Electronic Systems

- Mechanical Components

- Customer Specifications

- Surface Mount

- SMT

- Production Floor

- Brazing

- ESD

Updated January 8, 2025